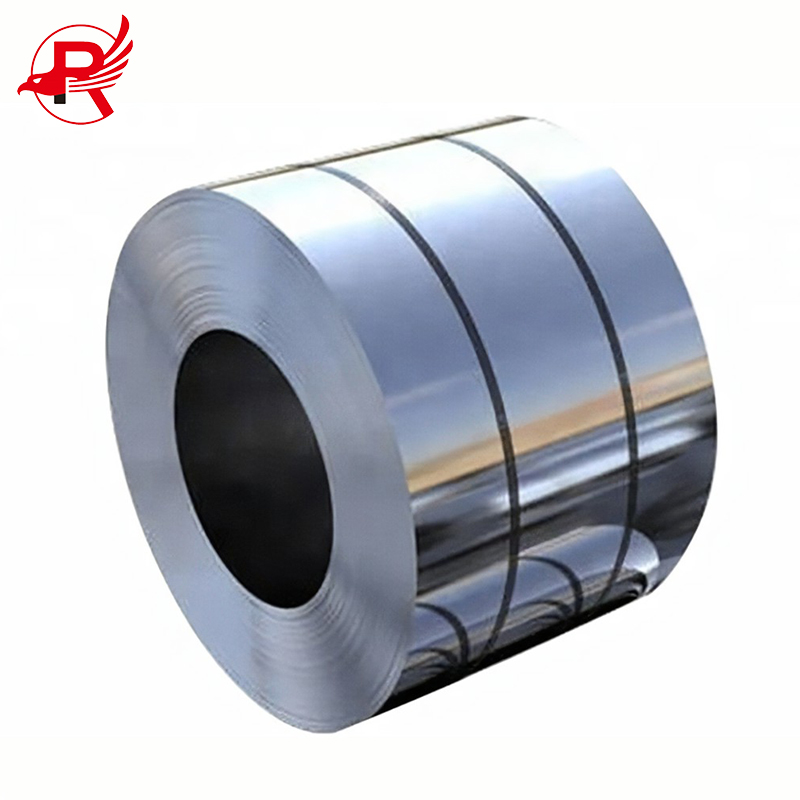

Ikhoyili Yensimbi Engagqwali Engu-1mm 2mm 3mm Ebandayo Egoqwe Ngensimbi Engagqwali engu-904 904L

| Igama Lomkhiqizo | Ikhoyili yensimbi engagqwali engu-904 904L |

| Ubulukhuni | 190-250HV |

| Ubukhulu | 0.02mm-6.0mm |

| Ububanzi | 1.0mm-1500mm |

| Umphetho | Isivalo/Isigayo |

| Ukubekezelela Ubuningi | ±10% |

| Ububanzi Bangaphakathi Be-Paper Core | Ingaphakathi lephepha elingu-Ø500mm, ingaphakathi elikhethekile lobubanzi futhi elingenalo ingaphakathi lephepha uma kucelwa ikhasimende |

| Ukuqedwa Komphezulu | I-NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror, njll. |

| Ukupakisha | Ikesi Lephalethi/Lokhuni |

| Imigomo Yokukhokha | Idiphozithi engu-30% TT kanye nebhalansi engu-70% ngaphambi kokuthunyelwa, i-100% LC lapho ibonwa |

| Isikhathi sokuthumela | Izinsuku zokusebenza eziyi-7-15 |

| I-MOQ | 200Kgs |

| Ichweba Lokuthumela | Ichweba laseShanghai/Ningbo |

| Isampula | Isampula yekhoyili yensimbi engagqwali engu-904 904L iyatholakala |

insimbi engagqwali enekhabhoni ephansi enikeza ukushibilika okuhle kakhulu, ukumelana okuhle nokugqwala kanye namandla aphezulu. Iyinto efanelekile yezinhlelo zokusebenza ezahlukahlukene okuhlanganisa imishini yokucubungula ukudla kanye nemishini yokucubungula amakhemikhali.

Okulandelayo uhlu lwezinye zezinhlelo zokusebenza ezivame kakhulu zamakhoyili ensimbi engagqwali angu-904 904L:

1. Imishini Yokucubungula Ukudla kanye Nemishini Yokucubungula Amakhemikhali

2. Izimboni Zikawoyela Negesi

3. Izicelo Zasolwandle

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Izakhi Zamakhemikhali Zekhoyili Yensimbi Engagqwali

| Ukwakheka Kwamakhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngezindlela ezahlukene zokucubungula zokugoqa okubandayo kanye nokucubungula kabusha ubuso ngemva kokugoqa, ukuqeda ubuso kwamakhoyili ensimbi engagqwali angu-904 904L kungaba nezinhlobo ezahlukene.

Ukucutshungulwa kwamakhoyili ensimbi engagqwali kubhekisela ekucutshungulweni nasekuphathweni komphezulu kwamakhoyili ensimbi engagqwali ukuze kuhlangatshezwane nezidingo ezithile zokusetshenziswa. Izindlela ezivamile zokucubungula zifaka phakathi ukusika, ukupholisha, ukudweba, njll. Ukusika ukusika ikhoyili yensimbi engagqwali ngokwesayizi edingekayo yikhasimende ukuze livumelane nezikhathi ezahlukene zokukhiqiza. Ukupholisha ukusebenzisa izindlela zemishini noma zamakhemikhali ukuze kufezwe umphumela okhanyayo ebusweni bamakhoyili ensimbi engagqwali, kuthuthukiswe ukuhlobisa kwayo kanye nobuhle bayo. Ukubhulasha kwenziwa ngokubhulasha okwenziwa ngomshini ukuze kunikezwe ubuso bomqulu wensimbi engagqwali ukuthungwa okuthile, kwandise ukumelana kwayo nokuklwebheka kanye nomphumela wokuhlobisa. Lokhu kwelashwa kungenziwa ngezifiso ngokwezidingo ezithile zamakhasimende ukuqinisekisa ukuthi ikhoyili yensimbi engagqwali inokusebenza okudingekayo kanye nokubukeka endaweni ethile yokusetshenziswa.

Inqubo yokukhiqiza ikhoyili yensimbi engagqwali yile: ukulungiswa kwezinto zokusetshenziswa - ukunamathisela kanye nokukha - (ukugaya okuphakathi) - ukugoqa - ukukha - ukukha - ukukha - ukulinganisa (ukugaya nokupholisha umkhiqizo okuqediwe) - ukusika, ukupakisha kanye nokugcina.

ukupakishwa olwandle okujwayelekile kwekhoyili yensimbi engagqwali engu-904 904L

Ukupakisha olwandle okujwayelekile kokuthumela ngaphandle:

Iphepha Elingangeni Manzi + Ifilimu ye-PVC + Ibhande Lebhande + Iphalethi Lokhuni noma Ikesi Lokhuni;

Ukupakishwa okwenziwe ngokwezifiso njengesicelo sakho (Ilogo noma okunye okuqukethwe kuyamukelwa ukuthi kuphrintwe ephaketheni);

Okunye ukupakisha okukhethekile kuzoklanywa njengesicelo sekhasimende;

Iphakheji:

Ukupakishwa kwamakhoyili ensimbi engagqwali kubalulekile ukuqinisekisa ukuvikeleka kwawo ngesikhathi sokuthuthwa. Inqubo yokupakishwa kufanele icabangele usayizi nesisindo samakhoyili ukuqinisekisa ukuthi afika lapho eya khona ngokuphephile. Okulandelayo yiminye yemikhuba evamile yokupakishwa kwamakhoyili ensimbi engagqwali:

1. Ibhokisi lokhuni: Lolu uhlobo lokupakisha olusetshenziswa kakhulu kuma-coil ensimbi engagqwali. Ibhokisi lokhuni liqinisekisa ukuthi ama-coil avikelekile ekulimaleni okufana nokuklwebheka noma ukufiphala ngesikhathi sokuthuthwa. Anikeza ukwesekwa okuhle kakhulu kwama-coil futhi amelana nokuphathwa nokulayisha okunzima.

2. Ukugqoka okuvikelayo: Ukugqoka okuvikelayo okufana nokupakisha uwoyela, iphepha noma ipulasitiki nakho kunganikeza ungqimba olwengeziwe lokuvikela ngesikhathi sokuthunyelwa. Ukugqoka kuvikela ubuso bekhoyili yensimbi engagqwali emswakama noma enhlabathini futhi kuvimbela ukugqwala noma ukugqwala.

3. Ukubopha: Bopha amakhoyili ensimbi ngamabhande ensimbi noma amabhande ensimbi ukuqinisekisa ukuthi awanyakazi ngesikhathi sokuthuthwa. Ukubopha kuvimbela futhi ikhoyili ukuthi yonakaliswe yimithelela evela kweminye imithwalo.

ezokuthutha:

Ukuthuthwa kwamakhoyili ensimbi engagqwali kubaluleke kakhulu njengokupakishwa kwawo. Kudingeka amasu okuphatha, ukulayisha, ukukhulula kanye nokuthumela ngendlela efanele ukuqinisekisa ukuthi amakhoyili awonakalanga noma aqhekekile. Nazi ezinye izindlela zokuthumela ezivamile zamakhoyili ensimbi engagqwali:

1. Ukulayisha nokukhipha imithwalo: Uma ulayisha futhi ukhipha imithwalo yensimbi engagqwali, kufanele uqaphele ukuvimbela umonakalo. Imithwalo kufanele ihlale iphakanyiswa, iphathwa futhi ithuthwe kusetshenziswa imishini ekhethekile njengama-crane noma ama-forklift.

2. Ukuvikela impahla: Impahla kumele ivalwe ngaphakathi kwe-trailer noma esitsheni ngesikhathi sokuthuthwa ukuze igweme ukuhamba noma ukugudluka. Ama-coil kufanele alayishwe ngendlela yokuthi aqine futhi angashayisani.

3. Khetha inkampani yokuthutha efanele: Kubalulekile futhi ukukhetha inkampani yokuthutha efanele. Inkampani yokuthutha kufanele ibe nolwazi lokuthutha amakhoyili ensimbi engagqwali. Kufanele ibe nemishini nabasebenzi abafanele ukuphatha impahla ngokuphepha nangokusebenza kahle.

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina. Ngaphandle kwalokho, sibambisana namabhizinisi amaningi kahulumeni, njenge-BAOSTEEL, i-SHOUGANG GROUP, i-SHAGANG GROUP, njll.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.