Ipayipi Lomugqa Wensimbi Yekhabhoni ye-API 5L B/X42 /X52 /X60 /X65 Psl2

| Amabanga | I-API 5L Ibanga B, X42, X52, X56, X60, X65, X70, X80 |

| Izinga Lokucaciswa | I-PSL1, i-PSL2 |

| Ububanzi Bobubanzi Bangaphandle | 1/2” kuya ku-2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 18”, 20”, 24” kuya ku-40”. |

| Ishejuli Yokujiya | I-SCH 10. I-SCH 20, I-SCH 40, I-SCH STD, I-SCH 80, I-SCH XS, kuya ku-SCH 160 |

| Izinhlobo Zokukhiqiza | Akunamthungo (Okugoqekile Okushisayo Nokugoqekile Okubandayo), I-Welded ERW (Okugoqekile Ukumelana Nogesi), I-SAW (Okugoqekile I-Arc Welded) ku-LSAW, DSAW, SSAW, HSAW |

| Uhlobo Lokuphela | Iziphetho ezigobile, Iziphetho ezicacile |

| Ibanga Lobude | I-SRL (Ubude Obungahleliwe Obubodwa), i-DRL (Ubude Obuphindwe Kabili Obungahleliwe), 20 FT (amamitha ayi-6), 40FT (amamitha ayi-12) noma, ngokwezifiso |

| Izigqoko Zokuvikela | ipulasitiki noma insimbi |

| Ukwelashwa Okuphezulu | Upende Owemvelo, Ovarnished, Omnyama, i-FBE, i-3PE (3LPE), i-3PP, i-CWC (Isisindo Esimboziwe Esiqinile) i-CRA Embozwe noma Enemigqa |

Ipayipi le-API 5L libhekisela epayipini lensimbi yekhabhoni elisetshenziswa ezinhlelweni zokudlulisa uwoyela negesi. Liphinde lisetshenziselwe ukuthutha ezinye izinto eziwuketshezi ezifana nomusi, amanzi, nodaka.

Imininingwane ye-API 5L ihlanganisa izinhlobo zokwenziwa ezihlanganisiwe nezingenamthungo.

Izinhlobo Ezihlanganisiwe: I-ERW, i-SAW, i-DSAW, i-LSAW, i-SSAW, ipayipi le-HSAW

Izinhlobo ezijwayelekile zepayipi elihlanganisiwe le-API 5L zimi kanje:

I-ERW: Ukushisela ukumelana nogesi kusetshenziselwa ipayipi elinobubanzi obungaphansi kwamasentimitha angu-24.

I-DSAW/ I-SAW: Ukushisela i-arc engaphansi kwamanzi okuphindwe kabili/ukushisela i-arc engaphansi kwamanzi kungenye indlela yokushisela engasetshenziswa esikhundleni se-ERW yepayipi elikhulu.

I-LSAW: Ukushisela kwe-Arc Engaphansi Komphetho we-Longitudinal kusetshenziselwa ipayipi elingafika kumasentimitha angu-48 ububanzi. Kwaziwa ngokuthi inqubo yokwakha i-JCOE.

I-SSAW/HSAW: Ukushisela i-arc engaphansi komhlaba okujikelezayo/ukushisela i-arc engaphansi komhlaba okujikelezayo okufika kumasentimitha angu-100 ububanzi bepayipi.

Izinhlobo Zepayipi Elingenamthungo: Ipayipi Elingenamthungo Eligoqekile Elishisayo kanye Nepayipi Elingenamthungo Eligoqekile Elibandayo

Ipayipi elingenamthungo livame ukusetshenziselwa amapayipi amancane anobubanzi (ngokuvamile angaphansi kwamasentimitha angu-24).

(Ipayipi lensimbi elingenamthungo livame ukusetshenziswa kakhulu kunepayipi elihlanganisiwe lamapayipi anobubanzi obungaphansi kuka-150 mm (amasentimitha angu-6).

Siphinde sinikeze ipayipi elikhulu elingenamthungo. Sisebenzisa inqubo yokukhiqiza egoqekayo ngokushisa, singakhiqiza ipayipi elingenamthungo elifinyelela kuma-intshi angu-20 (508 mm) ububanzi. Uma udinga ipayipi elingenamthungo elingaphezu kwama-intshi angu-20 ububanzi, singalikhiqiza sisebenzisa inqubo enwetshiwe ngokushisa efinyelela kuma-intshi angu-40 (1016 mm) ububanzi.

I-API 5L icacisa amamaki alandelayo: Ibanga B, X42, X46, X52, X56, X60, X65, X70, kanye ne-X80.

Kunezinhlobo eziningi ezahlukene zensimbi zamapayipi ensimbi e-API 5L njenge-Grade B, X42, X46, X52, X56, X60, X65, X70, kanye ne-X80. Ngokwanda kwe-grade yensimbi, ukulawulwa okulingana nekhabhoni kuqina kakhulu, amandla omshini aphezulu.

Futhi, ukwakheka kwamakhemikhali kwamapayipi angenamthungo nahlanganisiwe e-API 5L ebanga elithile akufani, ipayipi elihlanganisiwe linezidingo eziphezulu kakhulu kanye nenani elincane lekhabhoni nesibabule.

Ukwakheka Kwamakhemikhali kwepayipi le-PSL 1 elino-t ≤ 0.984” | |||||||

| Ibanga Lensimbi | Ingxenye yesisindo, i-% ngokusekelwe ekuhlaziyweni kokushisa nomkhiqizo a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| ubuningi b | ubuningi b | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | |

| Ipayipi Elingenamthungo | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| I-X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| I-X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| I-X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| I-X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Ipayipi Elihlanganisiwe | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| I-X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| I-X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| I-X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| I-X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; kanye ne-Mo ≤ 0.15%, | |||||||

| b. Kokuncishiswa ngakunye okungu-0.01% ngaphansi kokuhlushwa okuphezulu okucacisiwe kwekhabhoni, ukwanda okungu-0.05% ngaphezu kokuhlushwa okuphezulu okucacisiwe kwe-Mn kuvunyelwe, kuze kufike ku-1.65% kumagreyidi ≥ L245 noma B, kodwa ≤ L360 noma X52; kuze kufike ku-1.75% kumagreyidi > L360 noma X52, kodwa < L485 noma X70; futhi kuze kufike ku-2.00% kumagreyidi L485 noma X70., | |||||||

| c. Ngaphandle kokuthi kuvunyelwene ngenye indlela QAPHELA + V ≤ 0.06%, | |||||||

| d. I-Nb + V + TI ≤ 0.15%, | |||||||

| e. Ngaphandle kokuthi kuvunyelwene ngenye indlela., | |||||||

| f. Ngaphandle kokuthi kuvunyelwene ngenye indlela, QAPHELA + V = Ti ≤ 0.15%, | |||||||

| g. Akukho ukungezwa ngamabomu kuka-B okuvunyelwe futhi i-B eseleyo ≤ 0.001% | |||||||

| Ukwakheka Kwamakhemikhali kwepayipi le-PSL 2 elino-t ≤ 0.984” | |||||||||||||||||||||

| Ibanga Lensimbi | Ingxenye yesisindo, i-% ngokusekelwe ekuhlaziyweni kokushisa nomkhiqizo | I-Carbon Equiv a | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Okunye | CE IIW | CE Pcm | |||||||||||

| ubuningi b | ubuningi | ubuningi b | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ||||||||||||

| Ipayipi Elingenamthungo Nelihlanganisiwe | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| I-X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| I-X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Njengoba kuvunyelwene | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| I-X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| I-X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| I-X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | i,j | Njengoba kuvunyelwene | |||||||||||

| I-X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Njengoba kuvunyelwene | |||||||||||

| I-X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Njengoba kuvunyelwene | |||||||||||

| Ipayipi Elihlanganisiwe | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| I-X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| I-X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| I-X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| I-X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| I-X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| I-X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | i,j | .043f | 0.25 | ||||||||||

| I-X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | i,j | – | 0.25 | ||||||||||

| I-X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | i,j | – | 0.25 | ||||||||||

| a. Imikhawulo ye-SMLS t>0.787”, i-CE kufanele ibe njengoba kuvunyelwene. Imikhawulo ye-CEIIW esetshenziswayo fi C > 0.12% kanye nemikhawulo ye-CEPcm isebenza uma C ≤ 0.12%, | |||||||||||||||||||||

| b. Kokuncishiswa ngakunye okungu-0.01% ngaphansi komkhawulo ocacisiwe we-C, ukwenyuka okungu-0.05% ngaphezu komkhawulo ocacisiwe we-Mn kuvunyelwe, kuze kufike ku-1.65% wamamaki ≥ L245 noma B, kodwa ≤ L360 noma X52; kuze kufike ku-1.75% wamamaki > L360 noma X52, kodwa < L485 noma X70; kuze kufike ku-2.00% wamamaki ≥ L485 noma X70, kodwa ≤ L555 noma X80; futhi kuze kufike ku-2.20% wamamaki > L555 noma X80., | |||||||||||||||||||||

| c. Ngaphandle kokuthi kuvunyelwene ngenye indlela Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Ngaphandle uma kuvunyelwene ngenye indlela, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% kanye ne-Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Ngaphandle kokuthi kuvunyelwene ngenye indlela, | |||||||||||||||||||||

| g. Ngaphandle kokuthi kuvunyelwene ngenye indlela, i-Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Ngaphandle uma kuvunyelwene ngenye indlela, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% kanye ne-MO ≤ 0.50%, | |||||||||||||||||||||

| i. Ngaphandle uma kuvunyelwene ngenye indlela, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% kanye ne-MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Ngaphandle uma kuvunyelwene ngenye indlela, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% kanye ne-MO ≤ 0.80%, | |||||||||||||||||||||

| l. Kuwo wonke amamaki ephayiphi e-PSL 2 ngaphandle kwalawo mamaki anemibhalo yaphansi ephawulwe ngu-j, okulandelayo kuyasebenza. Ngaphandle kokuthi kuvunyelwene ngenye indlela akukho ukwengezwa okuhlosiwe kuka-B okuvunyelwe futhi okusele okungu-B ≤ 0.001%. | |||||||||||||||||||||

| I-PSL | Isimo Sokulethwa | Ibanga lepayipi |

| I-PSL1 | Njengoba kugoqwe, kujwayelekile, kwakheka ngokwejwayelekile | A |

| Njengoba kugoqwe, kugoqwe ngendlela ejwayelekile, kugoqwe ngendlela ejwayelekile, kwakheka ngendlela ejwayelekile, kugoqwe ngendlela ejwayelekile futhi kuqiniswe noma uma kuvunyelwene nge-Q&T SMLS kuphela | B | |

| Njengoba kugoqwe, kugoqwe ngendlela ejwayelekile, kugoqwe ngendlela ejwayelekile, kwakheka ngendlela ejwayelekile, kugoqwe ngendlela ejwayelekile futhi kuqiniswe ngendlela evamile | X42, X46, X52, X56, X60, X65, X70 | |

| I-PSL 2 | Njengoba kugoqwe | I-BR, X42R |

| Ukulungisa okugoqiwe, okwenziwa ngendlela evamile, okwenziwa ngendlela evamile noma okwenziwa ngendlela evamile futhi okwenziwa ngendlela evamile | I-BN, X42N, X46N, X52N, X56N, X60N | |

| Kucinyiwe futhi kuthambile | I-BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| I-Thermomechanical rolled noma i-thermomechanical eyakhiwe | I-BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| I-Thermomechanical rolled | I-X90M, X100M, X120M | |

| Okwanele (R, N, Q noma M) kwamabanga e-PSL2, kungokwamazinga ensimbi |

I-PSL1 ne-PSL2 zihlukile ngobubanzi bokuhlola kanye nangezakhiwo zazo zamakhemikhali nezomshini.

I-PSL2 iqine kakhulu kune-PSL1 ngokwakheka kwamakhemikhali, izakhiwo zokuthamba, ukuhlolwa komthelela, ukuhlolwa okungabhubhisi njalo njalo.

Ukuhlolwa Komthelela

I-PSL2 kuphela edinga ukuhlolwa komthelela: ngaphandle kwe-X80.

I-NDT: Ukuhlolwa Okungabhubhisi. I-PSL1 ayidingi ukuhlolwa okungabhubhisi uma kutholakala isaphulelo. Ukuhlolwa okungabhubhisi kuyasebenza. I-PSL2 iyakwenza lokho.

(Ukuhlolwa okungabhubhisi: Ukuhlolwa okungabhubhisi okujwayelekile kwe-API 5L kusebenzisa i-radiographic, i-ultrasonic, noma ezinye izindlela (ngaphandle kokubhubhisa izinto) ukuthola amaphutha nokungapheleli emipayipini.)

Ukupakisha kuyintongokuvamile unqunu, ukubopha ucingo lwensimbi, kakhulueqinile.

Uma unezidingo ezikhethekile, ungasebenzisaukupakishwa okuvikela ukugqwala, futhi muhle kakhulu.

Izinyathelo zokuphepha zokupakisha nokuthuthwa kwamapayipi ensimbi yekhabhoni

1.Ipayipi Lensimbi le-API 5Lkumele ivikelwe emonakalweni obangelwa ukushayisana, ukukhishwa kanye nokusikeka ngesikhathi sokuthuthwa, ukugcinwa kanye nokusetshenziswa.

2. Ngesikhathi uphatha amapayipi ensimbi yekhabhoni Kufanele uqaphele ukuqhuma, umlilo, ubuthi kanye nezinye izingozi, futhi uhambisane nezinqubo zokusebenza zokuphepha.

3. Ngesikhathi sokusetshenziswa,Ipayipi le-API 5L lensimbi yekhabhonikufanele kugwenywe ukuthintana namazinga okushisa aphezulu, izinto ezigqwalisayo, njll. Uma zisetshenziswa kulezi zindawo, amapayipi ensimbi yekhabhoni enziwe ngezinto ezikhethekile njengokumelana nokushisa okuphezulu kanye nokumelana nokugqwala kufanele akhethwe.

4. Ukukhethwa kwepayipi lensimbi yekhabhoni kufanele kube yinto efanelekile kanye nencazelo ngokuya ngezici eziphelele kufaka phakathi indawo yokusetshenziswa, uhlobo oluphakathi, ingcindezi, izinga lokushisa nokunye.

5. Ukuhlolwa okudingekayo kanye nokuhlolwa kufanele kwenziwe ngaphambi kokuba kusetshenziswe ipayipi lensimbi yekhabhoni ukuze kuqinisekiswe ukuthi ikhwalithi yalo isezingeni elifanele.

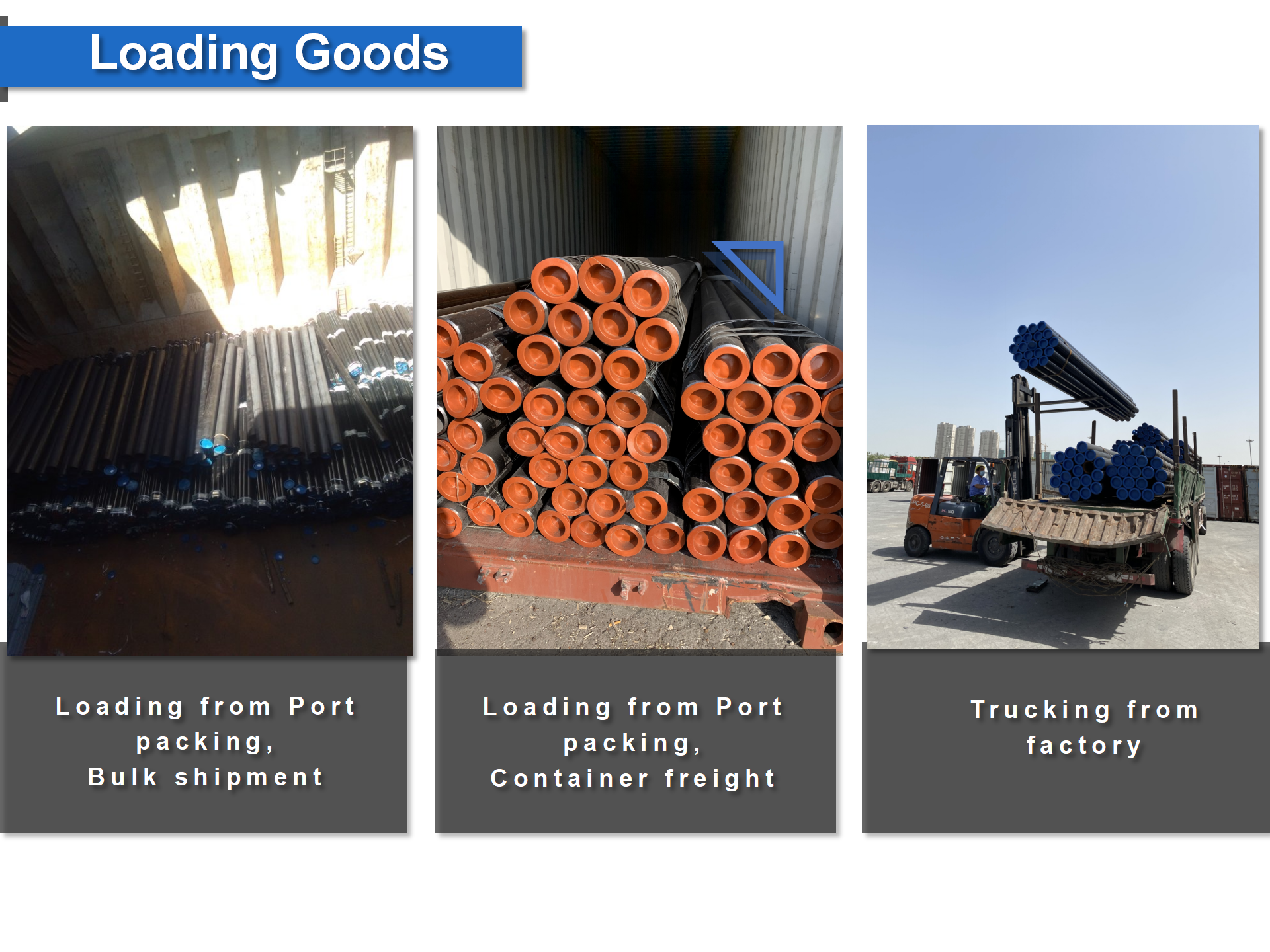

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (I-FCL noma i-LCL noma i-Bulk)

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi bamashubhu ensimbi ejikelezayo edolobhaneni laseDaqiuzhuang, edolobheni laseTianjin, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Singumhlinzeki wegolide weminyaka eyi-13 futhi samukela isiqinisekiso sokuhweba.