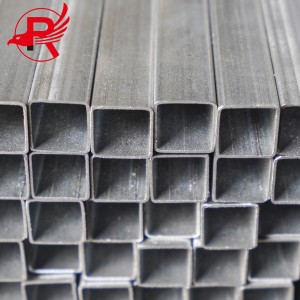

Ishubhu Lensimbi Engagqwali Eyi-Astm Standard St37 Eyi-Hollow Tube Eyisikwele Eyi-2.5 intshi

Ipayipi lesikwele elihlanganisiwe, eyaziwa nangokuthi ipayipi lensimbi elihlanganisiwe, elihlukaniswe nge-hot dip galvanized kanye ne-electric galvanized ezimbili, i-hot dip galvanized galvanized layer ebanzi, ene-coating efanayo, ukunamathela okuqinile, impilo yenkonzo ende kanye nezinye izinzuzo. Izindleko ze-electrogalvanizing ziphansi, indawo engaphezulu ayibushelelezi kakhulu, futhi ukumelana kwayo nokugqwala kubi kakhulu kunokwamapayipi ahlanganisiwe ahlanganisiwe ahlanganisiwe ashisayo.

Ipayipi elibandayo elihlanganisiwe: ipayipi elihlanganisiwe elihlanganisiwe elihlanganisiwe elihlanganisiwe elihlanganisiwe liyi-electric galvanizing, inani elihlanganisiwe lincane kakhulu, lingamagremu ayi-10-50 kuphela ngemitha yesikwele, ukumelana kwalo nokugqwala kuhluke kakhulu kunepayipi elishisayo elihlanganisiwe. Izitshalo zokukhiqiza amapayipi avamile ahlanganisiwe, ngenxa yekhwalithi, iningi alisebenzisi i-electric galvanizing (i-cold plating). Yilawo mabhizinisi amancane kuphela anemishini esidala asebenzisa i-electric galvanizing, vele, intengo ishibhile.

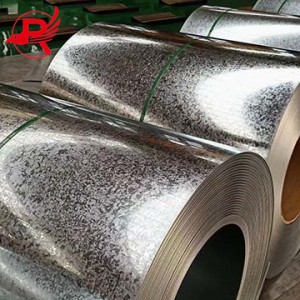

Ipayipi elifakwe ngogesi elishisayo

Insimbi encibilikisiwe ihlangana ne-matrix yensimbi ukuze ikhiqize ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kuhlanganiswe. I-hot dip galvanizing iwukuqala ngokukha ipayipi lensimbi, ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokukha, ngesisombululo samanzi se-ammonium chloride noma i-zinc chloride noma ithangi lesisombululo samanzi esixubile se-ammonium chloride kanye ne-zinc chloride ukuze kuhlanzwe, bese kufakwa ethangini le-hot dip plating. I-hot dip galvanizing inezinzuzo zokukhahlela okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside. Iningi lezinqubo enyakatho lisebenzisa inqubo yokugcwalisa kabusha i-zinc yepayipi le-coil eliqondile le-galvanizing.

Ipayipi elibandayo elihlanganisiwe

I-cold galvanizing igesi kagesi, inani le-galvanizing lincane kakhulu, liyi-10-50g/m2 kuphela, ukumelana kwayo nokugqwala kuhluke kakhulu kunepayipi elishisayo le-galvanizing. Abakhiqizi bamapayipi avamile e-galvanizing, ukuze baqinisekise ikhwalithi, iningi labo alisebenzisi i-electric galvanizing (i-cold plating). Yilawo mabhizinisi amancane kuphela anemishini esidala asebenzisa i-electric galvanizing, vele, amanani awo ashibhile. Esikhathini esizayo, amapayipi abandayo e-galvanizing awavunyelwe ukusetshenziswa njengamapayipi amanzi negesi.

Ipayipi lensimbi elicwengekileyo elishisayo

Ukusabela okuyinkimbinkimbi ngokomzimba nangokwekhemikhali kwenzeka phakathi kwe-substrate yeshubhu lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluqinile lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

Ngemva kokuthuthukiswa kwepayipi lensimbi elishisayo elihlanganisiwe ngawo-1960 kuya ku-1970, ikhwalithi yomkhiqizo ithuthuke kakhulu, kusukela ngo-1981 kuya ku-1989 kwanikezwa uMnyango Wezensimbi Wemikhiqizo Esezingeni Eliphezulu kanye nomklomelo Wesiliva Kazwelonke, ukukhiqizwa nakho kwanda iminyaka eminingi, kusukela ngo-1993 kwakhiqizwa amathani angaphezu kuka-400,000, kusukela ngo-1999 kwakhiqizwa amathani angaphezu kuka-600,000, futhi kwathunyelwa emazweni aseNingizimu-mpumalanga ye-Asia, e-Afrika, e-United States, eJapane, eJalimane nasezifundeni. Amapayipi ahlanganisiwe ahlanganisiwe asetshenziswa kakhulu njengamapayipi amanzi namapayipi egesi, kanti imininingwane evamile ingu-+12.5~+102 mm. Ngemva kweminyaka yawo-1990, ngenxa yokunaka kukahulumeni ekuvikeleni imvelo, ukulawulwa kwamabhizinisi angcolisa kakhulu kuya ngokuya kuba nzima, "imfucuza emithathu" ekhiqizwa ekukhiqizweni kwamapayipi agqunywe ngokushisa kunzima ukuyixazulula, okuhambisana nokuthuthukiswa okusheshayo kwamapayipi agqunywe ngokushisa ngensimbi engagqwali, amapayipi e-PVC namapayipi ahlanganisiwe, kanye nokuthuthukiswa okusheshayo kwamapayipi okwakha amakhemikhali, ukusetshenziswa kwamapayipi ensimbi agqunywe ngokushisa kuyavinjelwa, okwenza ukuthuthukiswa kwamapayipi agqunywe ngokushisa agqunywe ngokushisa kuye kwathinteka kakhulu. Ukuqina kanye nomkhawulo, ipayipi eligqunywe ngokushisa eligqunywe ngokushisa kamuva lathuthuka kancane kancane.

Ipayipi lensimbi elibandayo elihlanganisiwe

Ingqimba ye-zinc iyisimbozo sikagesi, kanti ungqimba lwe-zinc luhlanganiswe ngokuzimela nge-matrix yepayipi lensimbi. Ingqimba ye-zinc incane, kanti ungqimba lwe-zinc lumane lunamathele ku-matrix yepayipi lensimbi futhi kulula ukuwa. Ngakho-ke, ukumelana kwayo nokugqwala akukuhle. Ezakhiweni ezintsha zokuhlala, akuvunyelwe ukusebenzisa amapayipi ensimbi abandayo agqunywe ngamapayipi okuhambisa amanzi.

Isicelo

Ngenxa yokuthi ipayipi lesikwele eligoqiwe ligoqiwe epayipini lesikwele, ngakho-ke ububanzi bokusetshenziswa kwepayipi lesikwele eligoqiwe buye banda kakhulu kunepayipi lesikwele. Lisetshenziswa kakhulu odongeni lwekhethini, ekwakheni, ekukhiqizeni imishini, kumaphrojekthi okwakha insimbi, ekwakheni imikhumbi, ebhulokini lokuphehla amandla elanga, ubunjiniyela besakhiwo sensimbi, ubunjiniyela bamandla, isitshalo samandla, ezolimo kanye nemishini yamakhemikhali, udonga lwekhethini lengilazi, ishasi yezimoto, isikhumulo sezindiza njalo njalo.

| Igama Lomkhiqizo | Ipayipi Lensimbi Eyisikwele Elakhiwe Nge-Galvanised Square | |||

| Isimbozo seZinc | 35μm-200μm | |||

| Ubukhulu Bodonga | 1-5MM | |||

| Ubuso | I-galvanized eseyivele ikhona, I-galvanized ecwiliswe ngokushisa, I-electro galvanized, Imnyama, Ipendiwe, Ifakwe intambo, Iqoshwe, Isokhethi. | |||

| Ibanga | Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.BD | |||

| Ukubekezelelana | ±1% | |||

| Okunamafutha noma Okungamafutha | Okungagcotshwanga Amafutha | |||

| Isikhathi sokuthumela | Izinsuku ezi-3-15 (ngokusho kwenani langempela) | |||

| Ukusetshenziswa | Ubunjiniyela bezakhiwo, izakhiwo, imibhoshongo yensimbi, indawo yokuthutha imikhumbi, izicafolding, izinsika, izinqwaba zokuvimbela ukudilika komhlaba kanye nokunye izakhiwo | |||

| Iphakheji | Kumaqoqo ane-strip yensimbi noma kumaphakethe ezindwangu ezikhululekile, ezingalukiwe noma ngokwesicelo samakhasimende | |||

| I-MOQ | Ithani eli-1 | |||

| Isikhathi Sokukhokha | I-T/T | |||

| Isikhathi Sokuhweba | I-FOB, i-CFR, i-CIF, i-DDP, i-EXW | |||

Imininingwane

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.