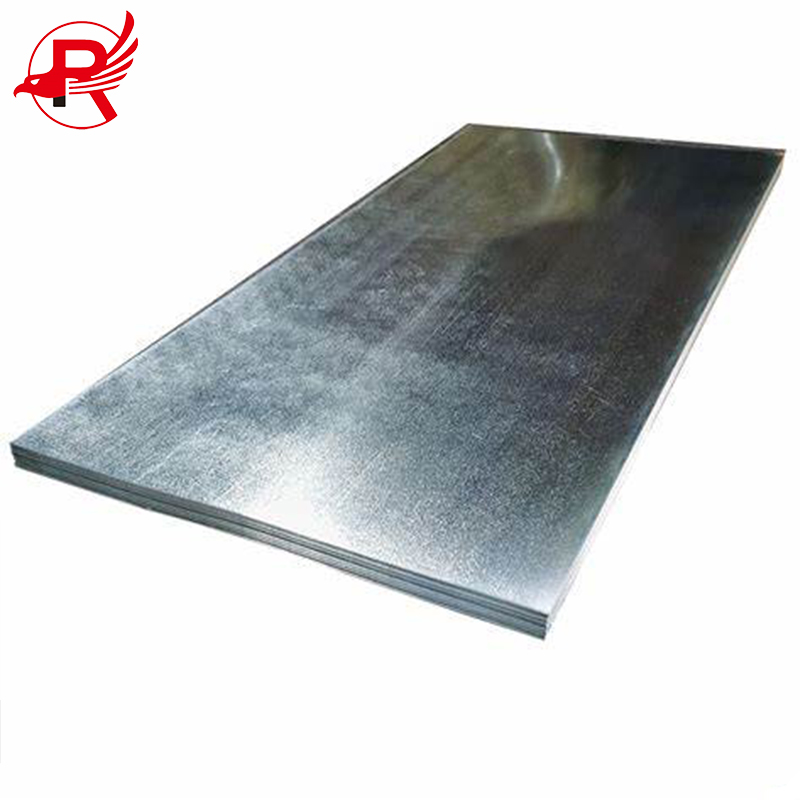

Ishidi Lensimbi Eliphezulu Eliphezulu Eliyi-0.27mm Elicwiliswe Ngokushisayo Elicwiliswe Nge-ASTM A653M-06a

Kunezinzuzo eziningana zokusebenzisa ishidi lensimbi elenziwe nge-galvanized:

1. Ukumelana nokugqwala: Ishidi lensimbi elihlanganisiwe limbozwe ngesendlalelo se-zinc, okwenza likwazi ukumelana nokugqwala kakhulu.

2. Ukuqina:Ipuleti Lensimbi Elakhiwe Nge-GalvanizedIhlala isikhathi eside kakhulu futhi ingamelana nezimo zezulu ezimbi kakhulu, okwenza kube ukukhetha okuhle kokusetshenziswa kwangaphandle.

3. Ukusebenza kahle kwezindleko: Ishidi lensimbi elihlanganisiwe lishibhile uma liqhathaniswa nezinye izinsimbi, okwenza kube ukukhetha okuthandwayo kwezicelo ezahlukahlukene.

4. Kulula ukusebenza ngayo: Ishidi lensimbi elihlanganisiwe kulula ukusebenza ngalo futhi lingakhiwa kalula libe nezimo nobukhulu obuhlukahlukene.

5. Ukugcinwa Okuphansi: Ishidi lensimbi elihlanganisiwe lidinga ukulungiswa okuncane, okwenza libe yinto engenazinkinga ezisetshenziswayo ezahlukahlukene.

6. Ukumelana nomlilo: Ishidi lensimbi elihlanganisiwe alishi, okwenza libe yindawo ekahle yokusetshenziswa ekwakheni nasezimbonini.

1. Ukumelana nokugqwala, ukupendwa kalula, ukwakheka kahle kanye nokushiselwa kwamabala.

2. Inezindlela eziningi zokusebenzisa, ikakhulukazi ezisetshenziselwa izingxenye zezinto zasekhaya ezincane ezidinga ukubukeka okuhle, kodwa ibiza kakhulu kune-SECC, ngakho abakhiqizi abaningi bashintshela ku-SECC ukuze bonge izindleko.

3. Ihlukaniswe yi-zinc: ubukhulu be-span kanye nobukhulu besendlalelo se-zinc kungabonisa ikhwalithi ye-galvanizing, uma incane futhi ikhulu kakhulu kungcono. Abakhiqizi bangangeza nokwelashwa okulwa nokunyathelisa iminwe. Ngaphezu kwalokho, ingahlukaniswa ngesendlalelo sayo, njenge-Z12, okusho ukuthi inani eliphelele lesendlalelo kuzo zombili izinhlangothi lingu-120g/mm.

Ishidi Lensimbi Eligayiwe, eyaziwa nangokuthi ishidi lensimbi elihlanganisiwe noma ishidi elihlanganiswe ne-zinc, uhlobo lweshidi lensimbi elihlanganiswe ngengqimba ye-zinc ukuze ligweme ukugqwala. Ukusetshenziswa kweshidi elihlanganisiwe kusakazeke kabanzi ngenxa yokuqina kwalo okuhle kakhulu kanye nokumelana nokugqwala. Lesi sihloko sihlola ukusetshenziswa kwalo okuhlukahlukene ezimbonini ezahlukene.

Imboni Yokwakha: Embonini yokwakha, amashidi e-galvanized avame ukusetshenziswa ekufakeni uphahla kanye nokufakwa kwe-cladding. Ngenxa yokuqina kwawo kanye nekhono lokubekezelela izimo zezulu ezinzima, asephenduke ukhetho oludumile lokufulela izindlu, ezentengiselwano, kanye nezezimboni. Amashidi e-galvanized avame ukusetshenziswa ekwakhiweni kwezakhiwo ezakhiwe ngohlaka lwensimbi, amabhuloho, kanye nemigwaqo emikhulu ngenxa yamandla nokuthembeka kwawo.

Imboni Yezimoto:Ipuleti Lensimbi Elishisayo Eligayiwezisetshenziswa kakhulu embonini yezimoto. Zisetshenziswa ekukhiqizeni imizimba yezimoto, i-chassis, nezinye izingxenye ngenxa yokumelana kwazo nokugqwala kanye nekhono lokubekezelela amazinga okushisa aphezulu kanye nomswakama ophezulu. Amashidi e-galvanized nawo asetshenziswa njengesivimbeli sokugqwala ukuze kwandiswe isikhathi sokuphila kwezingxenye zezimoto.

Imboni Yezolimo: Imboni yezolimo isebenzisa amashidi e-galvanized ukuze isetshenziswe ngezindlela ezahlukene njengokwenza amashede, ama-silo, izindlu zezilwane, kanye nothango. Lokhu kungenxa yekhono lawo lokubekezelela izimo zezulu ezahlukene nokumelana nokugqwala, okuqinisekisa ukuqina okuhlala isikhathi eside kwalezi zakhiwo.

Imboni Kagesi: Amashidi e-galvanized asetshenziswa kakhulu embonini kagesi ukudala izakhiwo nezingxenye ezihlala isikhathi eside nezihlala isikhathi eside njengezimbobo zemishini kagesi, imigudu yensimbi, izibani, kanye nezesekeli zocingo.

Imboni Yezinto Zikagesi: Amashidi e-galvanized nawo asetshenziswa kabanzi ekukhiqizweni kwezinto zikagesi zasekhaya ezahlukahlukene njengezinto zokupholisa umoya, iziqandisi, kanye nemishini yokuwasha. Lezi zinto zikagesi zidinga izinto eziqinile nezihlala isikhathi eside ezingamelana nokusabela kwamakhemikhali okubangelwa ukuchayeka ezintweni ezahlukene, okwenza amashidi e-galvanized abe ukukhetha okuhle.

Izicelo Zezimboni: Amashidi e-galvanized asetshenziswa ezinhlotsheni ezahlukene zezimboni ezifana namathangi okugcina izinto, amapayipi, kanye nemishini yokucubungula. Asetshenziswa kulezi zinhlelo ngoba angamelana nezimo zemvelo ezinzima kanye namakhemikhali agqwalisayo angase ahileleke ezinqubweni zezimboni.

| Izinga Lobuchwepheshe | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga Lensimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); noma kwamakhasimende Isidingo |

| Ubukhulu | imfuneko yekhasimende |

| Ububanzi | ngokwezidingo zekhasimende |

| Uhlobo Lokumboza | Insimbi Eshisayo Ecwiliswe Ngogesi (HDGI) |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa (C), Ukufaka uwoyela (O), Ukuvala i-Lacquer (L), Ukuphosphating (P), Okungaphathwanga (U) |

| Isakhiwo Somphezulu | Ukugqoka okujwayelekile kwe-spangle (NS), ukugqoka okuncishisiwe kwe-spangle (MS), okungena-spangle (FS) |

| Ikhwalithi | Kuvunywe yi-SGS, ISO |

| ID | 508mm/610mm |

| Isisindo sekhoyili | I-metric ton engu-3-20 nge-coil ngayinye |

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Imakethe yokuthumela ngaphandle | IYurophu, i-Afrika, i-Asia Ephakathi, iNingizimu-mpumalanga ye-Asia, iMpumalanga Ephakathi, iNingizimu Melika, iNyakatho Melika, njll. |

| Ithebula Lokuqhathanisa Ubukhulu Begeji | ||||

| Igeyiji | Okuncane | I-Aluminium | I-Galvanised | Insimbi Engagqwali |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina. Ngaphandle kwalokho, sibambisana namabhizinisi amaningi kahulumeni, njenge-BAOSTEEL, i-SHOUGANG GROUP, i-SHAGANG GROUP, njll.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.