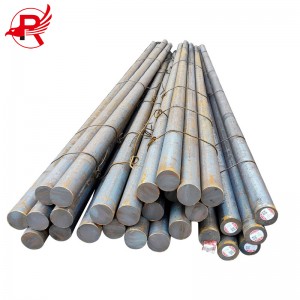

Umhlinzeki waseShayina Ukuthengiswa Okushisayo 12CrMo 15CrMo 20CrMo 30CrMo 42CrMo 35CrMo Ipuleti Lensimbi Yekhabhoni

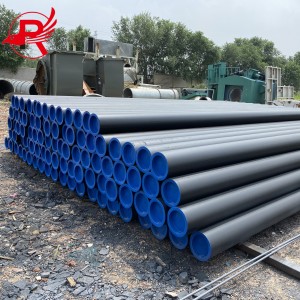

| Igama Lomkhiqizo | Ikhwalithi Engcono Kakhulu Ethengiswayo EshisayoIshidi Lensimbi Eligoqiwe Elishisayo |

| Izinto | 10#, 20#, 45#, 16Mn, A53(A,B), Q235, Q345, Q195, Q215, St37, St42, St37-2, St35.4, St52.4, ST35,20Mn2, 40Mn2, 50Mn2, 20MnV, 45B, 20Cr, 40Cr, 38CrSi, 12CrMo, 15CrMo, 20CrMo, 30CrMo, 42CrMo, 35CrMo, 12CrMoV, 12Cr1MoV, 25Cr2Mo1VA, 20CrV, 50CrVA, 40CrNi, 20MnMoB, 38CrMoAlA, 40CrNiMoA, |

| Ubukhulu | 1.5mm ~ 24mm |

| Usayizi | 3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm ngokwezifiso |

| Okujwayelekile | I-ASTM A53-2007, i-ASTM A671-2006, i-ASTM A252-1998, i-ASTM A450-1996, i-ASME B36.10M-2004, i-ASTM A523-1996, i-BS 1387, i-BS EN10296, i-BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

| Ibanga | I-A53-A369, Q195-Q345, ST35-ST52 |

| Ibanga A, Ibanga B, Ibanga C | |

| Ubuchwepheshe | I-Hot rolled |

| Ukupakisha | Iphakheji, noma nazo zonke izinhlobo zemibala ye-PVC noma njengezidingo zakho |

| Iziphetho Zepayipi | Isiphetho esilula/Esigoqekile, esivikelwe ngamakepisi epulasitiki kuzo zombili izinhlangothi, isikwele esinqunyiwe, esigoqiwe, esinomucu kanye nesixhunywayo, njll. |

| I-MOQ | Amathani angu-1, intengo yobuningi engeziwe izoba ngaphansi |

| Ukwelashwa Okuphezulu | 1. Isigayo siqediwe / Insimbi egayiwe / engagqwali |

| 2. Ukupenda kwe-PVC, Okumnyama nombala | |

| 3. Uwoyela obonakalayo, uwoyela olwa nokugqwala | |

| 4. Ngokwezidingo zamakhasimende | |

| Isicelo Somkhiqizo |

|

| Umsuka | Tianjin China |

| Izitifiketi | ISO9001-2008, SGS.BV, TUV |

| Isikhathi sokuthumela | Ngokuvamile zingakapheli izinsuku eziyi-7-10 ngemuva kokuthola inkokhelo kusengaphambili |

Insimbi engu-12CrMo:

Okuqukethwe kwe-Chromium: 0.90-1.20%

Okuqukethwe kwe-Molybdenum: 0.15-0.30%

Ukusetshenziswa Okuvamile: Imikhumbi yokucindezela, imishini yokushisa okuphezulu

Izakhiwo Zomshini: Amandla okudonsa angu-440-640 MPa, amandla okukhiqiza angu-235-295 MPa

Insimbi engu-15CrMo:

Okuqukethwe kwe-Chromium: 0.80-1.10%

Okuqukethwe kwe-Molybdenum: 0.40-0.55%

Ukusetshenziswa Okuvamile: Insimbi yebhoyila kanye nesitsha sokucindezela, izingxenye zesakhiwo

Izakhiwo Zomshini: Amandla okudonsa angu-440-640 MPa, amandla okukhiqiza angu-235-295 MPa

Insimbi engu-20CrMo:

Okuqukethwe kwe-Chromium: 0.70-1.00%

Okuqukethwe kwe-Molybdenum: 0.15-0.25%

Ukusetshenziswa Okuvamile: Amagiya, imiphini, izingxenye zezimoto

Izakhiwo Zomshini: Amandla okudonsa angu-885-1080 MPa, amandla okukhiqiza angu-685-885 MPa

Insimbi engu-30CrMo:

Okuqukethwe kwe-Chromium: 0.80-1.10%

Okuqukethwe kwe-Molybdenum: 0.15-0.25%

Ukusetshenziswa Okuvamile: Insimbi yesakhiwo semishini, izingxenye zezimoto

Izakhiwo Zomshini: Amandla okudonsa angu-900-1100 MPa, amandla okukhiqiza angu-650-850 MPa

Insimbi engu-42CrMo:

Okuqukethwe kwe-Chromium: 0.90-1.20%

Okuqukethwe kwe-Molybdenum: 0.15-0.25%

Ukusetshenziswa Okuvamile: Amagiya, imiphini, izingxenye zesakhiwo

Izakhiwo Zomshini: Amandla okunamathela angu-1080-1220 MPa, amandla okukhiqiza angu-930-1000 MPa

Insimbi engu-35CrMo:

Okuqukethwe kwe-Chromium: 0.17-0.37%

Okuqukethwe kwe-Molybdenum: 0.40-0.70%

Ukusetshenziswa Okuvamile: Izingxenye zesakhiwo, amagiya, imiphini

Izakhiwo Zomshini: Amandla okunamathela angu-1080-1220 MPa, amandla okukhiqiza angu-930-1000 MPa

| Ithebula Lokuqhathanisa Ubukhulu Begeji | ||||

| Igeyiji | Okuncane | I-Aluminium | I-Galvanised | Insimbi Engagqwali |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Ukusetshenziswa kwe-Hot Rolled Steel Plate

1. Insimu Yokwakha: Amapuleti ensimbi ashiswa ngokushisa avame ukusetshenziswa ekusekeleni, phansi, kumaphaneli odonga kanye nophahla lwezakhiwo zokwakha, okuhlanganisa izakhiwo ezinkulu ezifana namabhuloho nezakhiwo eziphakeme.

2. Insimu yokukhiqiza izimoto: amashidi ensimbi ashisiwe athatha indawo ebalulekile enqubweni yokukhiqiza izimoto, futhi ukusetshenziswa kwawo okuyinhloko ukukhiqiza izakhiwo zomzimba, iminyango, izembozo nezinye izingxenye.

3. Insimu yamandla: amapuleti ensimbi ashiswa ngokushisa asetshenziselwa ukukhiqiza izikhungo zamandla njengezikhungo zamandla, imibhoshongo yokudlulisa kanye namapayipi kawoyela.

4. Emkhakheni wokukhiqiza imishini: amapuleti ensimbi ashiswa ngokushisa angasetshenziswa ukukhiqiza amathuluzi omshini, amarobhothi kanye neminye imishini yezimboni.

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Ukugoqa okushisayo inqubo yokugaya ehilela ukugoqa insimbi ekushiseni okuphezulu

okungaphezu kwensimbiizinga lokushisa lokuphinda kusetshenziswe kabusha.

Ukupakisha ngokuvamile akunalutho, kubopha ucingo lwensimbi, kuqinile kakhulu.

Uma unezidingo ezikhethekile, ungasebenzisa ukupakisha okuvikela ukugqwala, futhi kube kuhle kakhulu.

Umkhawulo wesisindo sepuleti lensimbi

Ngenxa yobuningi obukhulu kanye nesisindo samapuleti ensimbi, amamodeli ezimoto afanele kanye nezindlela zokulayisha kudingeka kukhethwe ngokwezimo ezithile ngesikhathi sokuthuthwa. Ngaphansi kwezimo ezivamile, amapuleti ensimbi azothuthwa ngamaloli asindayo. Izimoto zokuthutha kanye nezesekeli kumele zihambisane nezindinganiso zokuphepha zikazwelonke, futhi kufanele kutholakale izitifiketi ezifanele zokufaneleka kwezokuthutha.

2. Izidingo zokupakisha

Kumapuleti ensimbi, ukupakisha kubaluleke kakhulu. Ngesikhathi senqubo yokupakisha, ubuso bepuleti lensimbi kumele buhlolwe ngokucophelela ukuze kutholakale umonakalo omncane. Uma kukhona umonakalo, kufanele kulungiswe futhi kuqiniswe. Ngaphezu kwalokho, ukuze kuqinisekiswe ikhwalithi iyonke kanye nokubukeka komkhiqizo, kunconywa ukusebenzisa izembozo zepuleti lensimbi zobungcweti zokupakisha ukuze kuvinjelwe ukuguguleka kanye nomswakama okubangelwa ukuthuthwa.

3. Ukukhetha umzila

Ukukhetha umzila kuyinkinga ebaluleke kakhulu. Uma uthutha amapuleti ensimbi, kufanele ukhethe umzila ophephile, ozolile futhi obushelelezi ngangokunokwenzeka. Kufanele uzame konke okusemandleni akho ukugwema izingxenye zomgwaqo eziyingozi njengemigwaqo eseceleni nemigwaqo yasezintabeni ukuze ugweme ukulahlekelwa ukulawula iloli nokugumbuqela futhi kubangele umonakalo omkhulu emthwalweni.

4. Hlela isikhathi ngendlela efanele

Uma kuthuthwa amapuleti ensimbi, isikhathi kufanele sihlelwe kahle futhi sibekelwe isikhathi esanele sokubhekana nezimo ezahlukahlukene ezingase ziphakame. Noma nini lapho kungenzeka, ukuthutha kufanele kwenziwe ngezikhathi ezingezona ezokuhamba ukuze kuqinisekiswe ukusebenza kahle kokuthutha nokunciphisa ingcindezi yethrafikhi.

5. Naka ukuphepha nokuvikeleka

Lapho kuthuthwa amapuleti ensimbi, kufanele kuqashelwe izindaba zokuphepha, njengokusebenzisa amabhande esihlalo, ukuhlola izimo zezimoto ngesikhathi, ukugcina izimo zomgwaqo zicacile, kanye nokunikeza izixwayiso ngesikhathi ezindaweni eziyingozi zomgwaqo.

Ngamafuphi, kunezinto eziningi okudingeka ziqashelwe lapho kuthuthwa amapuleti ensimbi. Kumelwe kucatshangelwe ngokuningiliziwe kusukela emikhawulweni yesisindo sepuleti lensimbi, izidingo zokupakisha, ukukhethwa komzila, amalungiselelo esikhathi, iziqinisekiso zokuphepha kanye nezinye izici ukuqinisekisa ukuthi ukuphepha kwempahla kanye nokusebenza kahle kwezokuthutha kuthuthukiswa kakhulu ngesikhathi senqubo yokuthutha. Isimo esingcono kakhulu.

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eDaqiuzhuang Village, eTianjin City, eShayina. Ngaphandle kwalokho, sibambisana namabhizinisi amaningi kahulumeni, njenge-BAOSTEEL, i-SHOUGANG GROUP, i-SHAGANG GROUP, njll.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

U: Ingabe unezinga eliphezulu lokukhokha?

A: Idiphozithi engu-30% nge-T/T, ibhalansi uma iqhathaniswa nekhophi ye-B/L nge-T/T.

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Singumhlinzeki wegolide weminyaka eyi-13 futhi samukela isiqinisekiso sokuhweba.