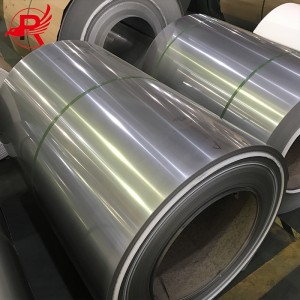

I-Cold Rolled Duplex Strip ASTM A240 2205 2507 Ikhoyili Yensimbi Engagqwali

| Igama Lomkhiqizo | Ikhoyili yensimbi engagqwali engu-2205 2507 |

| Amabanga | 201/EN 1.4372/SUS201 |

| Ubulukhuni | 190-250HV |

| Ubukhulu | 0.02mm-6.0mm |

| Ububanzi | 1.0mm-1500mm |

| Umphetho | Isivalo/Isigayo |

| Ukubekezelela Ubuningi | ±10% |

| Ububanzi Bangaphakathi Be-Paper Core | Ingaphakathi lephepha elingu-Ø500mm, ingaphakathi elikhethekile lobubanzi futhi elingenalo ingaphakathi lephepha uma kucelwa ikhasimende |

| Ukuqedwa Komphezulu | I-NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror, njll. |

| Ukupakisha | Ikesi Lephalethi/Lokhuni |

| Imigomo Yokukhokha | Idiphozithi engu-30% TT kanye nebhalansi engu-70% ngaphambi kokuthunyelwa, i-100% LC lapho ibonwa |

| Isikhathi sokuthumela | Izinsuku zokusebenza eziyi-7-15 |

| I-MOQ | 200Kgs |

| Ichweba Lokuthumela | Ichweba laseShanghai/Ningbo |

| Isampula | Isampula yekhoyili yensimbi engagqwali engu-2205 2507 iyatholakala |

Insimbi engagqwali engu-2205 2507 enikeza ukushibilika okuhle kakhulu, ukumelana okuhle nokugqwala kanye namandla aphezulu. Iyinto efanelekile yezinhlelo zokusebenza ezahlukahlukene okuhlanganisa imishini yokucubungula ukudla kanye nemishini yokucubungula amakhemikhali.

Okulandelayo uhlu lwezinye zezinhlelo zokusebenza ezivame kakhulu zamakhoyili ensimbi engagqwali angu-2205 2507:

1. Imishini Yokucubungula Ukudla kanye Nemishini Yokucubungula Amakhemikhali

2. Izimboni Zikawoyela Negesi

3. Izicelo Zasolwandle

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Izakhi Zamakhemikhali Zekhoyili Yensimbi Engagqwali

| Ukwakheka Kwamakhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ukwelashwa kobuso bezinsimbi zensimbi engagqwali kubaluleke kakhulu, okuthinta ngqo ukubukeka, ukumelana nokugqwala kanye nezinkambu ezisebenzayo zezinsimbi zensimbi engagqwali. Ukwelashwa okuvamile kobuso bezinsimbi zensimbi engagqwali kufaka phakathi i-2B, i-BA, i-NO.4, njll.

Ukwelashwa kobuso be-2B yikona okuvame kakhulu, okunokukhanya okungcono nokushelela, futhi kufaneleka kakhulu ezinhlotsheni eziningi zezicelo ezinezidingo ezijwayelekile, njengokwakha, ifenisha, njll.

Ukwelashwa kobuso be-BA kutholakala ngokupholisha nge-electrolytic, kanti ukuqeda kobuso kuphakeme. Kufanelekile ngezikhathi ezinezidingo eziphezulu zokuqeda kobuso, njengezinto zasekhishini, izinto zikagesi, njll.

Ukwelashwa kobuso be-NO.4 kutholakala ngokupholisha ibhande, kanti ubuso bubonisa ukuthungwa okuqandisiwe. Kufanelekile ngezikhathi ezidinga ukuhlobisa kanye nokulwa nokuklwebheka, njengamaphaneli okuhlobisa, ingaphakathi le-lifti, njll.

Ngaphezu kwezindlela zokwelapha ubuso ezivamile ezingenhla, amakhoyili ensimbi engagqwali angenziwa ngokwezifiso ngokwezidingo zamakhasimende, njengokupholisha esibukweni, ukudweba ucingo, njll., ukuze kuhlangatshezwane nezidingo ezikhethekile zezinkambu ezahlukene.

Ukwelashwa kobuso bezinsimbi zensimbi engagqwali kubalulekile ekusetshenzisweni kwayo kokugcina kanye nokusebenza kwayo. Ukwelashwa kobuso bezinsimbi zensimbi engagqwali okuvamile kuhlanganisa i-2B, i-BA, i-NO.4, njll.

Ukwelashwa kobuso be-2B yikona okuvame kakhulu, okunokukhanya okungcono nokushelela, futhi kufaneleka kakhulu ezinhlotsheni eziningi ezinezidingo ezijwayelekile, njengokwakhiwa, ifenisha, njll. Le ndlela yokwelapha isebenzisa ukuhluza kobuso ngemva kokuguqa okubandayo ukuze kwenziwe ubuso bube bushelelezi, kodwa ayinawo umphumela wesibuko.

Ukwelashwa kobuso be-BA kutholakala ngokupholisha nge-electrolytic. Ukuphela kobuso kuphakeme futhi kukhombisa umphumela wesibuko. Kufanelekile ngezikhathi ezidinga ukuqeda kobuso okuphezulu, njengezinto zasekhishini, izinto zikagesi, njll. Lokhu kwelashwa kunikeza ukubukeka okuhle kakhulu kanye nokumelana nokugqwala.

Ukwelashwa kobuso be-NO.4 kutholakala ngokupholisha ibhande, kanti ubuso bubonisa ukuthungwa okuqandisiwe. Kufanelekile ngezikhathi ezidinga ukuhlobisa kanye nokulwa nokuklwebheka, njengamaphaneli okuhlobisa, ingaphakathi le-lifti, njll. Le ndlela yokwelapha ingandisa ukuhlobisa kanye nobuhle bekhoyili yensimbi engagqwali, ngenkathi ithuthukisa ukumelana kwayo nokuguguleka.

Ngaphezu kwezindlela ezivamile zokwelapha ubuso, amakhoyili ensimbi engagqwali angenziwa ngokwezifiso ngokwezidingo zamakhasimende, njengokupholisha esibukweni, ukudweba ucingo, njll., ukuze kuhlangatshezwane nezidingo ezikhethekile zezinkambu ezahlukene. Ngakho-ke, ukukhetha indlela efanele yokwelapha ubuso yamakhoyili ensimbi engagqwali kubaluleke kakhulu ekusebenzeni nasekusetshenzisweni kokugcina komkhiqizo.

Inqubo yokukhiqiza ikhoyili yensimbi engagqwali yile: ukulungiswa kwezinto zokusetshenziswa - ukunamathisela kanye nokukha - (ukugaya okuphakathi) - ukugoqa - ukukha - ukukha - ukukha - ukulinganisa (ukugaya nokupholisha umkhiqizo okuqediwe) - ukusika, ukupakisha kanye nokugcina.

Ukufakwa kwamabhokisi kanye nokupakishwa kwamakhoyili ensimbi engagqwali kuyizixhumanisi ezibalulekile ukuqinisekisa ukuphepha kokuthuthwa komkhiqizo kanye nokuvikela ikhwalithi yomkhiqizo. Ngokuvamile, ukufakwa kwamabhokisi kanye nokupakishwa kwamakhoyili ensimbi engagqwali kulandela izinyathelo ezilandelayo:

Okokuqala, ama-coil ensimbi engagqwali kudingeka ahlolwe ngekhwalithi ngokuqinile ngaphambi kokuba afakwe emabhokisini ukuqinisekisa ukuthi indawo ayinayo imihuzuko nokungcola, futhi ihlangabezana nezidingo nezindinganiso zamakhasimende.

Okwesibili, khetha izinto zokupakisha ezifanele ngokwezincazelo kanye nobuningi bemiqulu yensimbi engagqwali. Izinto zokupakisha ezivamile zifaka ama-pallet okhuni, amabhokisi, amafilimu epulasitiki, njll. Kuma-roll amakhulu ensimbi engagqwali, avame ukupakishwa kuma-pallet okhuni ukuqinisekisa ukuthi imikhiqizo ayicindezelwa futhi ayiguquki ngesikhathi sokuthuthwa.

Bese, beka imiqulu yensimbi engagqwali kahle ezintweni zokupakisha, bese uthatha izinyathelo ezifanele zokuzivikela, njengokuqinisa ama-pallet okhuni, ukugoqa ngefilimu yepulasitiki, njll., ukuvimbela ukushayisana nomonakalo ngesikhathi sokuthuthwa.

Okokugcina, amakhoyili ensimbi engagqwali apakishiwe ayaphawulwa futhi aqoshwe, okuhlanganisa imininingwane yomkhiqizo, ubuningi, usuku lokukhiqiza kanye nolunye ulwazi, futhi amalebula okuhlonza acacile anamathiselwe ephaketheni ukuze kube lula ukuwahlonza nokuphatha.

Phakathi nayo yonke inqubo yokufaka ama-crate nokupakisha, kuyadingeka ukusebenza ngokuhambisana ngokuqinile nezindinganiso nezimfuneko ezifanele ukuqinisekisa ukuthi ama-coil ensimbi engagqwali awonakaliswa ngesikhathi sokuthuthwa nokuqinisekisa ukuthi ikhwalithi nobuqotho bomkhiqizo kufinyelela kumakhasimende.

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina. Ngaphandle kwalokho, sibambisana namabhizinisi amaningi kahulumeni, njenge-BAOSTEEL, i-SHOUGANG GROUP, i-SHAGANG GROUP, njll.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.