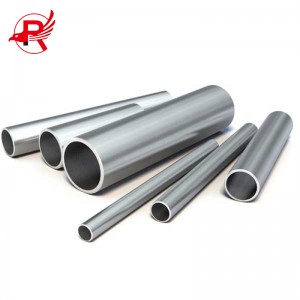

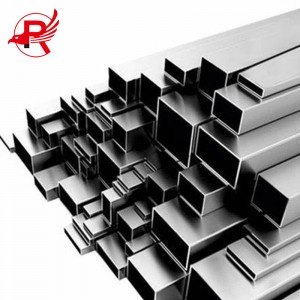

Ipayipi/Ipayipi Lensimbi Engagqwali Elihlanganisiwe Lokuhlobisa

| Igama Lomkhiqizo | Ipayipi eliyindilinga lensimbi engagqwali |

| Okujwayelekile | I-ASTM AISI DIN, EN, GB, JIS |

| Ibanga Lensimbi

| Uchungechunge lwama-200: 201,202 |

| Uchungechunge lwama-300: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| Uchungechunge lwe-400: 409L,410,410s,420j1,420j2,430,444,441,436 | |

| Insimbi Ephindwe Kabili: 904L, 2205, 2507, 2101, 2520, 2304 | |

| Ububanzi Bangaphandle | 6-2500mm (njengoba kudingeka) |

| Ubukhulu | 0.3mm-150mm (njengoba kudingeka) |

| Ubude | 2000mm/2500mm/3000mm/6000mm/12000mm (njengoba kudingeka) |

| Ubuchwepheshe | Akunamthungo |

| Ubuso | Inombolo 1 2B BA 6K 8K Isibuko No.4 HL |

| Ukubekezelelana | ±1% |

| Imigomo Yentengo | I-FOB, i-CFR, i-CIF |

Ipayipi lensimbi engagqwali uhlobo lwensimbi eyindilinga ende engenalutho, esetshenziswa kakhulu kumapayipi ezokuthutha ezimbonini afana ne-petroleum, imboni yamakhemikhali, ukwelashwa kwezokwelapha, ukudla, imboni elula, ithuluzi lomshini, njll., kanye nezingxenye zesakhiwo somshini. Ngaphezu kwalokho, lapho ukugoba namandla okugoba kufana, isisindo silula, ngakho-ke sisetshenziswa kabanzi ekwenziweni kwezingxenye zomshini kanye nezakhiwo zobunjiniyela. Isetshenziswa futhi njengefenisha nezinto zasekhishini, njll.

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Izakhi Zamakhemikhali Zepayipi Lensimbi Engagqwali

| Ukwakheka Kwamakhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa izindlela ezahlukene zokucubungula ukugoqa okubandayo kanye nokucubungula kabusha ubuso ngemva kokugoqa, ukuqeda ubuso kwensimbi engagqwaliibhaAma-s angaba nezinhlobo ezahlukene.

Ikhwalithi yendawo yensimbi engagqwali ibaluleke kakhulu njengoba ithinta ngqo ukumelana kwayo nokugqwala. Ukugqwala kuyinto yemvelo eyenzeka lapho izinsimbi zisabela endaweni yamakhemikhali ezizungezile, njengomoya noma umswakama.

Ngensimbi engagqwali, i-chromium eku-alloy yakha ungqimba oluvikelayo ebusweni oluvimbela insimbi ukuthi ingasabeli endaweni ezungezile. Lolu ngqimba lubizwa ngokuthi ifilimu yokudlulisa. Kodwa-ke, ifilimu engasebenzi ensimbi engagqwali ayiyona engenakubhujiswa. Uma ubuso bonakalisiwe noma bungcolile, ifilimu ingaqhuma, ishiye insimbi isengozini yokugqwala. Yingakho ukugcina ukuhlanzeka nobuqotho bezindawo zensimbi engagqwali kubalulekile.

Kunezindlela eziningana zokuthuthukisa ikhwalithi yezindawo zensimbi engagqwali. Enye indlela ukusebenzisa inqubo ebizwa ngokuthi i-passivation. Lokhu kuhilela ukwelapha indawo ngesisombululo esikhethekile esisusa noma yikuphi ukungcola futhi sithuthukise izakhiwo zokuvikela zefilimu engasebenzi. I-passivation ingafezwa ngamasu ahlukahlukene njengokugeza ngamakhemikhali noma ukupholisha nge-electro.

Enye indlela yokugcina ikhwalithi yezindawo zensimbi engagqwali ukuhlanza nokulungisa njalo. Izindawo zensimbi engagqwali kufanele zihlanzwe ngensipho ethambile kanye nendwangu ethambile, futhi noma yimaphi amabala aqinile noma ukushintsha kombala kungasuswa ngemikhiqizo yokuhlanza ekhethekile.

Sekukonke, ukubaluleka kokuqedwa kwensimbi engagqwali akunakugcizelelwa ngokweqile. Ikhwalithi yobuso ibalulekile ukuqinisekisa ukuqina nokuqina kwesikhathi sento. Ngokulandela izinqubo zokuhlanza nokulungisa ezifanele, insimbi engagqwali ingaqhubeka nokunikeza ukusebenza okuhle kakhulu kanye nokukhanga kobuhle iminyaka eminingi ezayo.

Insimbi engagqwali yaziwa ngokuqina kwayo, ukumelana nokugqwala kanye nokuguquguquka kwayo. Ivame ukusetshenziswa ezinhlotsheni ezahlukene zokusebenza okuhlanganisa nokukhiqizwa kwamapayipi.

Ipayipi lensimbi engagqwali lisetshenziswa kabanzi ezindaweni zezimboni kanye nasekwakheni izakhiwo nezakhiwo. Inqubo yokukhiqiza ipayipi lensimbi engagqwali iyinqubo eyinkimbinkimbi ehilela izinyathelo eziningi.

Impahla eluhlaza

Isinyathelo sokuqala ekukhiqizeni ipayipi lensimbi engagqwali ukuthola izinto zokusetshenziswa. Ingxenye eyinhloko yensimbi engagqwali yinsimbi, kodwa ihlanganiswa nezinye izinto ukuze iyinike izakhiwo ezihlukile. Lezi zinto zifaka phakathi i-nickel, i-chromium kanye ne-molybdenum. Izinto zokusetshenziswa zikhethwa ngokucophelela futhi zihlanganiswe ngokulingana ukuze kukhiqizwe izinga elifunekayo lensimbi engagqwali. Lezi zingxenye bese zincibilikiswa ndawonye esithandweni sokushisa okuphezulu, lapho zihlangana khona ukuze zakhe i-alloy. Uma i-alloy isibunjiwe, ithululelwa esikhumbeni ukuqala inqubo yokubumba izinto. Izikhunta, ngokuvamile ezenziwe ngesihlabathi noma nge-ceramic, zenzelwe ukwakha amashubhu angenalutho ekupheleni kwenqubo. Ngemva kokuba i-alloy ithululelwe esikhumbeni, ivunyelwe ukuba iphole futhi iqine. Isimo sokugcina yishubhu enemiphetho eqinile kanye nobuso obungalingani.

skrola

Isinyathelo esilandelayo kule nqubo ukugoqa. Ithubhu liphakelwa ngochungechunge lwama-roller acindezela futhi abumbe izinto, okuholela endaweni elingana kakhulu nobubanzi obuhambisanayo. Ithubhu bese idlula ku-mandrel ukuqinisekisa ukuthi iyindilinga ngokuphelele nokuthi ubukhulu bodonga buyafana. Le nqubo, eyaziwa ngokuthi usayizi, ibalulekile ekuqinisekiseni ukuthi umkhiqizo oqediwe uhlangabezana nezidingo ezidingekayo.

Ukusika Nokuqeda

Uma ipayipi selilinganisiwe, sekuyisikhathi sokusika nokuqeda. Lokhu kuhlanganisa ukusika ipayipi libe nobude obufunekayo kanye nokushelela noma yimiphi imiphetho noma ama-burrs aqinile. Ipayipi libe selipholishwa ukuze liqede kahle futhi likhazimule. Le nqubo isiza ukwandisa ukumelana nokugqwala kwepayipi futhi ilinike ukubukeka okukhangayo.

Ukuhlolwa Nokuhlolwa

Imikhiqizo eqediwe kumele ihlolwe futhi ihlolwe ngokucophelela ngaphambi kokuba ithengiswe. Hlola ithubhu ukuze ibone noma yiziphi iziphambeko ezifana nokuqhekeka noma amabala okugqwala. Iphinde yaphumelela ekuhlolweni kwamandla, ukuqina kanye nokumelana nokugqwala. Uma ipayipi seliphumelele kuzo zonke izivivinyo nokuhlolwa okudingekayo, selilungele ukusetshenziswa. Ipayipi lensimbi engagqwali elikhiqizwa kusetshenziswa le nqubo lisetshenziswa ezimbonini ezahlukahlukene, okuhlanganisa ezokwakha, uwoyela negesi, kanye nokukhiqiza.

Ngamafuphi, ukukhiqizwa kwamapayipi ensimbi engagqwali kuyinqubo eyinkimbinkimbi enezinyathelo eziningi ehilela izigaba eziningi kusukela ezintweni zokusetshenziswa kuya emikhiqizweni eqediwe. Kudinga ukunakwa ngokucophelela emininingwaneni, ukunemba kanye nokulawulwa kwekhwalithi ukuqinisekisa ukuthi umkhiqizo oqediwe uhlangabezana nezimfuneko ezidingekayo futhi ufanelekela izinhlelo zokusebenza ezahlukahlukene.

Ukupakisha ngokuvamile akunalutho, kubopha ucingo lwensimbi, kuqinile kakhulu.

Uma unezidingo ezikhethekile, ungasebenzisa ukupakisha okuvikela ukugqwala, futhi kube kuhle kakhulu.

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Ikhasimende Lethu

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi bepayipi lensimbi ejikelezayo edolobheni laseTianjin, eShayina

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.