Ipayipi/Ishubhu Yensimbi Eyindilinga Ehlanganisiwe Yefektri Eqondile

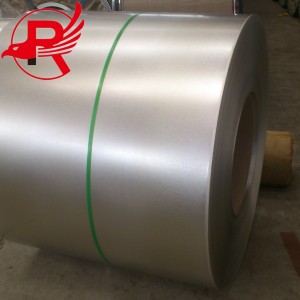

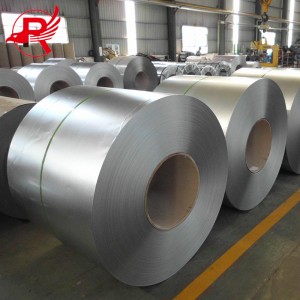

Ipayipi elishisayo elihlanganisiweKwenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kuhlanganiswe kabili. I-hot dip galvanizing iwukuqala ngokukha i-iron tube. Ukuze kususwe i-iron oxide ebusweni be-iron tube, ngemva kokukha, ihlanzwa ethangini nge-ammonium chloride noma i-zinc chloride solution noma i-mixed aqueous solution ye-ammonium chloride kanye ne-zinc chloride, bese ithunyelwa ethangini elishisayo lokukha i-hot dip plating. I-hot dip galvanizing inezinzuzo zokukhahlela okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo se-iron tube kanye ne-metal bath ukuze kwakheke ungqimba lwe-compact zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe ne-zinc emsulwa kanye ne-iron tube matrix. Ngakho-ke, ukumelana kwayo nokugqwala kunamandla.

Izici

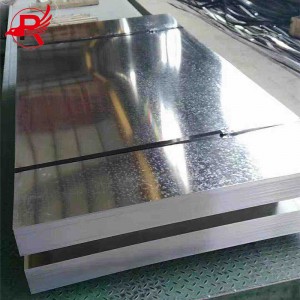

1. Ukumelana nokugqwala: I-Galvanizing iyindlela yokuvimbela ukugqwala engabizi futhi ephumelelayo evame ukusetshenziswa. Cishe ingxenye yomkhiqizo we-zinc emhlabeni isetshenziswa kule nqubo. I-zinc ayigcini nje ngokwakha ungqimba oluqinile lokuvikela phezu kwensimbi, kodwa futhi inomphumela wokuvikela i-cathodic. Lapho ungqimba lwe-zinc lonakele, lusengavimbela ukugqwala kwezinto eziyisisekelo sensimbi ngokuvikela i-cathodic.

2. Ukusebenza kahle kokugoba nokubanda kanye nokushisela: kusetshenziswa kakhulu izinga eliphansi lensimbi yekhabhoni, izidingo zinokusebenza okuhle kokugoba nokubanda kanye nokushisela, kanye nokusebenza okuthile kokunyathela

3. Ukukhanya: Kukhanya kakhulu, okwenza kube yisithiyo ekushiseni

4, ukuqina kwesembozo kuqinile, ungqimba oluhlanganisiwe lwakha isakhiwo esikhethekile sensimbi, lesi sakhiwo singamelana nomonakalo womshini ekuthuthweni nasekusetshenzisweni.

Isicelo

Ipayipi elihlanganisiwe elishisayo liyinqubo yokufaka ungqimba lwe-zinc phezu kwamapayipi ensimbi avamile. Ngokufaka ipayipi lensimbi oketshezini oluncibilikisiwe lwe-zinc, kwakheka ungqimba lwe-zinc olufanayo noluqinile, ngaleyo ndlela kuthuthukiswe ukumelana nokugqwala kanye nokuphila kwenkonzo yepayipi lensimbi. Amapayipi ahlanganisiwe ashisayo asetshenziswa kabanzi emikhakheni eyahlukahlukene.

Okokuqala, emkhakheni wokwakha, amapayipi agqitshwe ngokushisa avame ukusetshenziselwa ukusekela izakhiwo zezakhiwo kanye nezinhlelo zamapayipi angaphandle. Ngenxa yokumelana nokugqwala kwawo kanye nokumelana nesimo sezulu, amapayipi agqitshwe ngokushisa angasetshenziswa kumapayipi angaphandle, izikhonkwane zezitebhisi, izinsimbi zokubiyela nezinye izingxenye. Angamelana ngempumelelo nezinto ezigqwalisayo emoyeni futhi andise isikhathi sawo sokusebenza.

Okwesibili, emkhakheni wezimboni, amapayipi agqitshwe ngokushisa avame ukusetshenziswa ezinhlelweni zamapayipi ukuthutha uketshezi, amagesi kanye nezinto zokusetshenziswa zamakhemikhali. Isibonelo, ezimbonini zikaphethiloli, zamakhemikhali, zemithi kanye nezinye, amapayipi agqitshwe ngokushisa angasetshenziswa ukuthutha imidiya eyahlukahlukene, futhi ukumelana kwawo nokugqwala kanye nokumelana nokushisa okuphezulu kungaqinisekisa ukusebenza okuphephile kohlelo lwamapayipi.

Ngaphezu kwalokho, emkhakheni wezolimo, amapayipi agqitshwe ngogesi ashisayo nawo anezicelo ezibalulekile. Angasetshenziswa ezinhlelweni zokunisela epulazini, izakhiwo zokusekela imishini yezolimo, njll. ngoba ukumelana kwawo nokugqwala kungamelana nokuguguleka kwamapayipi ngamakhemikhali enhlabathini.

Ngokuvamile, ipayipi elifakwe ngogesi elishisayo linezicelo ezibalulekile ekwakheni, embonini, kwezolimo nakweminye imikhakha. Ukumelana kwayo nokugqwala kanye nokumelana nesimo sezulu kuyenza ibe ngenye yezinto ezifanelekile zezinhlelo nezakhiwo ezahlukahlukene zamapayipi.

Amapharamitha

| Igama lomkhiqizo | Ipayipi Elihlanganisiwe |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njll. |

| Ubude | I-standard 6m kanye ne-12m noma njengemfuneko yamakhasimende |

| Ububanzi | 600mm-1500mm, ngokwezidingo zamakhasimende |

| Ezobuchwepheshe | I-Hot Cwilisa Lashukumisaipayipi |

| Isimbozo seZinc | 30-275g/m2 |

| Isicelo | Kusetshenziswa kabanzi ezakhiweni ezahlukene zezakhiwo, amabhuloho, izimoto, ama-bracker, imishini njll. |

Imininingwane

Izendlalelo ze-zinc zingakhiqizwa kusukela ku-30g kuya ku-550g futhi zinganikezwa nge-hotdip galvanizing, i-electric galvanizing kanye ne-pre-galvanizing. Inikeza isendlalelo sokusekela ukukhiqizwa kwe-zinc ngemva kombiko wokuhlola. Ubukhulu bukhiqizwa ngokuhambisana nenkontileka. Inqubo yenkampani yethu ukubekezelela ubukhulu kungaphakathi kuka-±0.01mm. Izendlalelo ze-zinc zingakhiqizwa kusukela ku-30g kuya ku-550g futhi zinganikezwa nge-hotdip galvanizing, i-electric galvanizing kanye ne-galvanizing. Inikeza isendlalelo sokusekela ukukhiqizwa kwe-zinc ngemva kombiko wokuhlola. Ubukhulu bukhiqizwa ngokuhambisana nenkontileka. Inqubo yenkampani yethu ukubekezelela ubukhulu kungaphakathi kuka-±0.01mm. I-laser cutting nozzle, i-nozzle ibushelelezi futhi icocekile. Ipayipi elihlanganisiwe eliqondile, ubuso obuhlanganisiwe. Isika ubude kusukela kumamitha angu-6-12, singanikeza ubude obujwayelekile baseMelika obungu-20ft 40ft. Noma singavula isikhunta ukuze senze ngokwezifiso ubude bomkhiqizo, njenge-13 metres njll. 50.000m warehouse. Ikhiqiza okungaphezu kwalokho Amathani angu-5,000 ezimpahla ngosuku. Ngakho-ke singabanikeza isikhathi sokuthumela esisheshayo kanye nentengo yokuncintisana.

Ipayipi elihlanganisiwe liyinto yokwakha evamile futhi lisetshenziswa ngezindlela eziningi. Enkambisweni yokuthunyelwa, ngenxa yethonya lezici zemvelo, kulula ukubangela izinkinga ezifana nokugqwala, ukuguquka noma ukulimala kwepayipi lensimbi, ngakho-ke kubaluleke kakhulu ekupakisheni nasekuthuthweni kwamapayipi ahlanganisiwe. Leli phepha lizokwethula indlela yokupakisha ipayipi elihlanganisiwe enkambisweni yokuthunyelwa.

2. Izidingo zokupakisha

1. Ubuso bepayipi lensimbi kufanele buhlanzeke futhi bome, futhi akufanele kube khona amafutha, uthuli kanye nezinye izinsalela.

2. Ipayipi lensimbi kumele lifakwe iphepha elimbozwe ngepulasitiki elinezingqimba ezimbili, ungqimba lwangaphandle lumbozwe ngephepha lepulasitiki elinobukhulu obungaphansi kuka-0.5mm, kanti ungqimba lwangaphakathi lumbozwe ngefilimu yepulasitiki ye-polyethylene esobala enobukhulu obungaphansi kuka-0.02mm.

3. Ipayipi lensimbi kumele limakwe ngemva kokupakisha, futhi uphawu kufanele lufake uhlobo, imininingwane, inombolo yebhetshi kanye nosuku lokukhiqizwa kwepayipi lensimbi.

4. Ipayipi lensimbi kufanele lihlukaniswe futhi lipakishwe ngokwezigaba ezahlukene njengezincazelo, usayizi nobude ukuze kube lula ukulayisha nokukhipha impahla kanye nokugcina impahla.

Okwesithathu, indlela yokupakisha

1. Ngaphambi kokupakisha ipayipi elifakwe i-galvanized, ubuso bepayipi kufanele buhlanzwe futhi buphathwe ukuze kuqinisekiswe ukuthi ubuso buhlanzekile futhi bomile, ukuze kugwenywe izinkinga ezifana nokugqwala kwepayipi lensimbi ngesikhathi sokuthunyelwa.

2. Lapho kufakwa amapayipi agqitshwe nge-galvanized, kufanele kuqashelwe ukuvikelwa kwamapayipi ensimbi, kanye nokusetshenziswa kwe-red cork splints ukuqinisa zombili iziphetho zamapayipi ensimbi ukuvimbela ukuguquka nokulimala ngesikhathi sokupakisha nokuthuthwa.

3. Izinto zokupakisha zepayipi elihlanganisiwe kumele zibe nomphumela wokumelana nomswakama, ukumelana namanzi kanye nokugqwala ukuqinisekisa ukuthi ipayipi lensimbi alithintwa umswakama noma ukugqwala ngesikhathi senqubo yokuthumela.

4. Ngemva kokuba ipayipi elihlanganisiwe selipakishiwe, naka i-sunscreen engangeni umswakama kanye ne-sunscreen ukuze ugweme ukuchayeka isikhathi eside elangeni noma endaweni enomswakama.

4. Izinyathelo Zokuqapha

1. Ukupakishwa kwamapayipi agqitshwe nge-galvanized kumele kunake ukulinganiswa kosayizi nobude ukuze kugwenywe imfucuza nokulahleka okubangelwa ukungalingani kosayizi.

2. Ngemva kokupakishwa kwepayipi elihlanganisiwe, kuyadingeka ukulimaka nokulihlukanisa ngesikhathi ukuze kube lula ukuphatha kanye nokugcina impahla.

3, ukupakishwa kwamapayipi agqitshiwe, kufanele kunake ukuphakama nokuqina kokupakishwa kwezimpahla, ukugwema ukuthambekela kwezimpahla noma ukupakishwa okuphezulu kakhulu okungabangela umonakalo ezimpahleni.

Lokhu okungenhla kuyindlela yokufaka ipayipi elihlanganisiwe enqubweni yokuthumela, okuhlanganisa nezidingo zokufaka, izindlela zokufaka kanye nezinyathelo zokuphepha. Lapho ufaka futhi uthutha, kuyadingeka ukusebenza ngokuhambisana nemithethonqubo, futhi uvikele ngempumelelo ipayipi lensimbi ukuqinisekisa ukufika okuphephile kwezimpahla endaweni oya kuyo.

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.