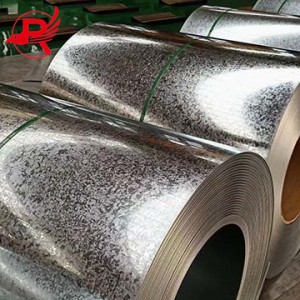

Ikhoyili Yensimbi Ehlanganisiwe Eshisayo Ecwiliswe Ngobandayo Ye-JIS SGCC

Ikhoyili ye-Galvanised, ishidi lensimbi elincane elicwiliswa ebhavini le-zinc elincibilikisiwe ukuze ubuso balo bunamathele kungqimba lwe-zinc. Njengamanje, likhiqizwa kakhulu ngenqubo eqhubekayo yokugaya, okungukuthi, ipuleti lensimbi eligoqiwe licwiliswa njalo ebhavini nge-zinc encibilikisiwe ukwenza ipuleti lensimbi eligoqiwe; Ishidi lensimbi eligoqiwe elihlanganisiwe. Lolu hlobo lwepuleti lensimbi lwenziwa nangendlela yokushisa, kodwa lishiswa cishe ku-500 ℃ ngokushesha ngemva kokuphuma ethangini, ukuze lakhe ungqimba lwe-zinc nensimbi oluhlanganisiwe. Le coil ehlanganisiwe inokuqina okuhle kokumboza kanye nokushibilika. Amakhoyili e-galvanized angahlukaniswa ngamakhoyili e-galvanized aqhutshwa ngokushisa kanye namakhoyili e-galvanized aqhutshwa ngokushisa aqhutshwa ngokushisa, asetshenziswa kakhulu ekwakheni, ezintweni zasekhaya, ezimotweni, ezitsheni, ezokuthutha kanye nasezimbonini zasekhaya. Ikakhulukazi, ukwakhiwa kwesakhiwo sensimbi, ukukhiqizwa kwezimoto, ukukhiqizwa kwempahla yokugcina izimpahla zensimbi kanye neminye imboni. Isidingo semboni yokwakha kanye nemboni yokukhanya yimakethe eyinhloko yekhoyili ehlanganisiwe, ebalelwa cishe ku-30% wesidingo seshidi ehlanganisiwe.

Iikhoyili yensimbi ehlanganisiweInqubo yokukhiqiza ingafaka izinyathelo ezilandelayo:

1. Ukulungiswa kwezinto ezingavuthiwe: Inqubo iqala ngokukhethwa kwensimbi esezingeni eliphezulu, kulandelwe ukuhlanza ukuze kususwe noma yikuphi ukungcola okungaphezulu okungase kubangele amaphutha kumkhiqizo wokugcina.

2. Ukujikijela Okubandayo: Insimbi ehlanziwe idluliselwa ochungechungeni lwemiqulu ukuze inciphise ukujiya kwayo futhi ithuthukise ukuqeda kwayo.

3. Ukufakwa kwe-Annealing: Umcu wensimbi ube usufudunyezwa esithandweni somoya esilawulwayo ukuze uthambise futhi kube lula ukuwusebenzisa nge-galvanize.

4. Ukuhlanganisa nge-galvanizing: Umcu wensimbi ucwiliswa ebhavini le-zinc encibilikisiwe ukuze umbozwe ngengqimba ye-zinc ukuvimbela ukugqwala. Le nqubo ibizwa ngokuthi i-hot dip galvanizing.

5. Ukupholisa: Insimbi egayiwe ipholiswa kuze kufike ekushiseni kwegumbi ngaphambi kokuba igoqwe.

6. Ukulinganisa Ukucindezeleka: Ikhoyili ibe isidlula ku-tension leveler, esusa noma yikuphi ukucindezeleka okusele futhi iqinisekise ukuthi ikhoyili inesimo esiyisicaba nesihambisanayo.

7. Ikhwalithi yokulawula: Okokugcina, amakhoyili ensimbi agqitshiwe ayahlolwa ukuze kutholakale ukuthi awanazo yini izinkinga futhi ahlolwe ukuqinisekisa ukuthi ayahlangabezana nezimfuneko ezidingekayo.

Amakhoyili ensimbi aqediwe asetshenziswa ezinhlotsheni eziningi zezicelo okuhlanganisa izimboni zokwakha, zezimoto kanye nezamagesi.

1. Ukumelana Nokugqwala: I-Galvanizing iyindlela engabizi futhi ephumelelayo yokuvimbela ukugqwala evame ukusetshenziswa. Cishe ingxenye yokukhiqizwa kwe-zinc emhlabeni isetshenziselwa le nqubo. I-zinc ayigcini nje ngokwakha ungqimba oluqinile lokuvikela phezu kwensimbi, kodwa futhi inomphumela wokuvikela i-cathodic. Lapho ungqimba lwe-zinc lonakele, lusengavimbela ukugqwala kwezinto ezisekelwe ensimbini ngokuvikela i-cathodic.

2. Ukusebenza Okuhle Kokugoba Okubandayo Nokushisela: insimbi ephansi yekhabhoni isetshenziswa kakhulu, okudinga ukugoba okuhle okubandayo, ukusebenza kahle kokushisela kanye nokusebenza okuthile kokunyathela

3. Ukukhanya: ukukhanya okuphezulu, okwenza kube yisithiyo sokushisa

4. Isembozo Siqinile, futhi isembozo se-zinc sakha isakhiwo esikhethekile se-metallurgical, esingamelana nomonakalo wemishini ngesikhathi sokuthuthwa nokusetshenziswa.

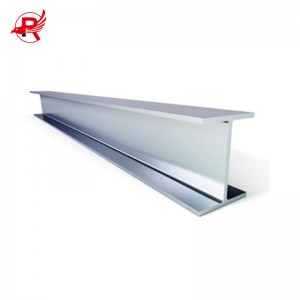

Amakhoyili Ensimbi AqinisiweImikhiqizo isetshenziswa kakhulu kwezokwakha, embonini elula, ezimotweni, kwezolimo, kwezilwane, kwezokudoba, kwezentengiselwano nakwezinye izimboni. Imboni yokwakha isetshenziswa kakhulu ukukhiqiza amaphaneli ophahla alwa nokugqwala kanye nama-grating ophahla ezakhiweni zezimboni nezomphakathi; Embonini elula, isetshenziselwa ukukhiqiza amagobolondo ezinto zasekhaya, oshimula bomphakathi, izinto zasekhishini, njll. Embonini yezimoto, isetshenziswa kakhulu ukukhiqiza izingxenye zezimoto ezingagqwali, njll.; Ezolimo, kwezilwane kanye nokudoba kusetshenziswa kakhulu njengendawo yokugcina nokuthutha ukudla, amathuluzi okucubungula inyama nemikhiqizo yasemanzini, njll.; Isetshenziswa kakhulu ukugcina nokuthutha izinto zokwakha kanye namathuluzi okupakisha.

| Igama lomkhiqizo | Ikhoyili yensimbi egayiwe |

| Ikhoyili yensimbi egayiwe | I-ASTM, EN, JIS, GB |

| Ibanga | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, I-SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; I-SQ CR22 (230), I-SQ CR22 (255), I-SQ CR40 (275), I-SQ CR50 (340), I-SQ I-CR80(550), i-CQ, i-FS, i-DDS, i-EDDS, i-SQ CR33 (230), i-SQ CR37 (255), i-SQCR40 (275), i-SQ CR50 (340), i-SQ CR80 (550); noma Imfuneko Yekhasimende |

| Ubukhulu | 0.10-2mm kungaba ngokwezifiso ngokufanele mfuneko yakho |

| Ububanzi | 600mm-1500mm, ngokwezidingo zamakhasimende |

| Ezobuchwepheshe | Ikhoyili Eshisayo Ecwilisiwe Egayiwe |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa i-passivation, Ukufaka uwoyela, ukuvala i-lacquer, i-phosphate, okungalungiswanga |

| Ubuso | i-spangle ejwayelekile, i-mis spangle, ekhanyayo |

| Isisindo sekhoyili | Ithani eli-2-15metric ngekhoyili ngayinye |

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Isicelo | ukwakhiwa kwesakhiwo, i-gring yensimbi, amathuluzi |

1. Angakanani amanani akho?

Amanani ethu angashintsha kuye ngokuthi ukunikezwa kwempahla kuyatholakala yini kanye nezinye izici zemakethe. Sizokuthumelela uhlu lwamanani olubuyekeziwe ngemuva kokuxhumana nenkampani yakho.

nathi ukuze uthole ulwazi olwengeziwe.

2. Ingabe unenani elincane kakhulu le-oda?

Yebo, sidinga ukuthi wonke ama-oda aphesheya abe nenani elincane eliqhubekayo le-oda. Uma ufuna ukuthengisa kabusha kodwa ngamanani amancane kakhulu, sincoma ukuthi uhlole iwebhusayithi yethu.

3. Ungakwazi yini ukunikeza amadokhumenti afanele?

Yebo, singanikeza imibhalo eminingi kufaka phakathi Izitifiketi Zokuhlaziya/Ukuhambisana; Umshwalense; Umsuka, kanye neminye imibhalo yokuthumela ngaphandle lapho kudingeka khona.

4. Singakanani isikhathi esimaphakathi sokuhola?

Kumasampula, isikhathi sokuhola cishe siyizinsuku eziyi-7. Ekukhiqizweni ngobuningi, isikhathi sokuhola siyizinsuku ezi-5-20 ngemuva kokuthola inkokhelo yediphozithi. Izikhathi zokuhola ziqala ukusebenza uma

(1) sesiyitholile idiphozithi yakho, futhi (2) sinemvume yakho yokugcina yemikhiqizo yakho. Uma izikhathi zethu zokukhokha zingasebenzi ngesikhathi sakho sokugcina, sicela ubuyekeze izidingo zakho ngokuthengisa kwakho. Kuzo zonke izimo sizozama ukuhlangabezana nezidingo zakho. Ezimweni eziningi siyakwazi ukwenza kanjalo.

5. Yiziphi izinhlobo zezindlela zokukhokha ozamukelayo?

U-30% kusengaphambili nge-T/T, u-70% uzoba ngaphambi kokuthunyelwa okuyisisekelo ku-FOB; u-30% kusengaphambili nge-T/T, u-70% uma kuqhathaniswa nekhophi ye-BL eyisisekelo ku-CIF.