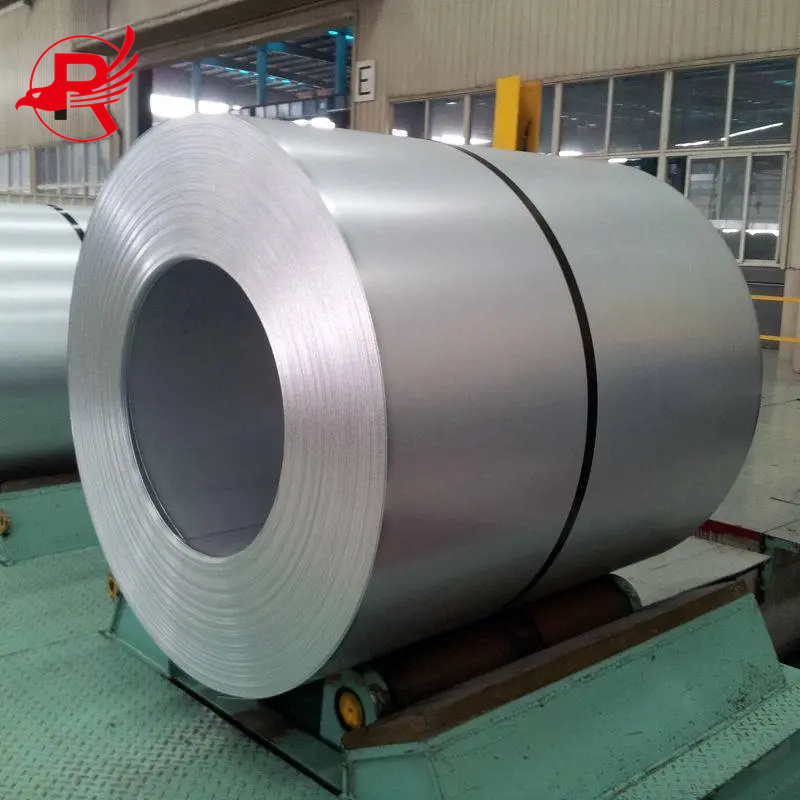

Intengo Yefektri I-Cold Rolled Grade 420 430 440 SS Strip Stainless Steel Coil

| Igama Lomkhiqizo | 420 430 440ikhoyili yensimbi engagqwali |

| Ubulukhuni | 190-250HV |

| Ubukhulu | 0.02mm-6.0mm |

| Ububanzi | 1.0mm-1500mm |

| Umphetho | Isivalo/Isigayo |

| Ukubekezelela Ubuningi | ±10% |

| Ububanzi Bangaphakathi Be-Paper Core | Ingaphakathi lephepha elingu-Ø500mm, ingaphakathi elikhethekile lobubanzi futhi elingenalo ingaphakathi lephepha uma kucelwa ikhasimende |

| Ukuqedwa Komphezulu | I-NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror, njll. |

| Ukupakisha | Ikesi Lephalethi/Lokhuni |

| Imigomo Yokukhokha | Idiphozithi engu-30% TT kanye nebhalansi engu-70% ngaphambi kokuthunyelwa |

| Isikhathi sokuthumela | Izinsuku zokusebenza eziyi-7-15 |

| I-MOQ | 200Kgs |

| Ichweba Lokuthumela | Ichweba laseShanghai/Ningbo |

| Isampula | Isampula yekhoyili yensimbi engagqwali engu-420 430 440 iyatholakala |

I-201 iyinsimbi engagqwali enomsoco ophansi enikeza ukushibilika okuhle kakhulu, ukumelana okuhle nokugqwala kanye namandla aphezulu. Iyinto efanelekile yezinhlelo zokusebenza ezahlukahlukene okuhlanganisa imishini yokucubungula ukudla kanye nemishini yokucubungula amakhemikhali.

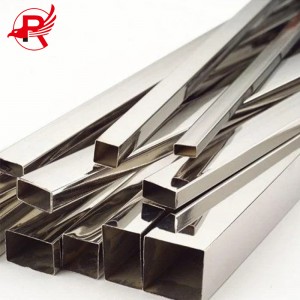

Okulandelayo uhlu lwezinye zezicelo ezivame kakhulu zamakhoyili ensimbi engagqwali:

1. Imishini Yokucubungula Ukudla kanye Nemishini Yokucubungula Amakhemikhali

2. Izimboni Zikawoyela Negesi

3. Izicelo Zasolwandle

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Izakhi Zamakhemikhali Zekhoyili Yensimbi Engagqwali

| Ukwakheka Kwamakhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngezindlela ezahlukene zokucubungula zokugoqa okubandayo kanye nokucubungula kabusha ubuso ngemva kokugoqa, ukuqeda ubuso kwamakhoyili ensimbi engagqwali angu-201 kungaba nezinhlobo ezahlukene.

Ukucubungula ubuso bezinsimbi zensimbi engagqwali kune-NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright kanye nokunye ukuqedwa kobuso, njll.

NO.1: Ubuso obungu-1 bubhekisela ebusweni obutholakala ngokwelashwa ngokushisa kanye nokuphotha ngemva kokuphotha okushisayo komugqa wensimbi engagqwali. Kuwukususa isikali se-oxide emnyama esikhiqizwa ngesikhathi sokuphotha okushisayo kanye nokwelashwa ngokushisa ngokuphotha noma izindlela ezifanayo zokwelapha. Lokhu kungukucubungula ubuso obungu-1. Ubuso obungu-1 bumhlophe njengesiliva futhi abunawo umbala. Kusetshenziswa kakhulu ezimbonini ezingamelani nokushisa kanye nezingamelani nokugqwala ezingadingi ukukhanya kobuso, njengemboni yotshwala, imboni yamakhemikhali kanye nezitsha ezinkulu.

2B: Ubuso be-2B buhlukile kobuso be-2D ngoba bubushelelezi nge-roller ebushelelezi, ngakho-ke bukhanya kakhulu kunobuso be-2D. Ubulukhuni bobuso Inani le-Ra elilinganiswa yithuluzi lingu-0.1 ~0.5μm, okuwuhlobo lokucubungula oluvame kakhulu. Lolu hlobo lobuso bensimbi engagqwali luyizinto eziningi kakhulu, lufanelekela izinjongo ezijwayelekile, olusetshenziswa kabanzi embonini yamakhemikhali, ephepheni, ephethroli, kwezokwelapha nakwezinye izimboni, futhi lungasetshenziswa njengodonga lwekhethini lesakhiwo.

Ukuqeda Okuqinile kwe-TR: Insimbi engagqwali ye-TR ibizwa nangokuthi insimbi eqinile. Amazinga ayo ensimbi amele angama-304 nama-301, asetshenziselwa imikhiqizo edinga amandla aphezulu nokuqina, njengezimoto zesitimela, amabhande okuhambisa, izipilingi nama-gasket. Umgomo ukusebenzisa izici zokuqinisa umsebenzi zensimbi engagqwali ye-austenitic ukwandisa amandla nokuqina kwepuleti lensimbi ngezindlela zokusebenza ezibandayo njengokugoqa. Izinto eziqinile zisebenzisa amaphesenti ambalwa kuya kwamashumi ambalwa amaphesenti okugoqa okuthambile ukuze kuthathelwe indawo ukuthamba okuthambile kobuso besisekelo se-2B, futhi akukho ukugoqa okwenziwayo ngemva kokugoqa. Ngakho-ke, ubuso be-TR obunzima bezinto eziqinile buwubuso obugoqa ngemva kokugoqa okubandayo.

Okugoqekile Okukhanyayo 2H: Ngemva kwenqubo yokugoqa, imichilo yensimbi engagqwali izocutshungulwa ngokugoqekile okukhanyayo. Umuchilo ungapholiswa ngokushesha ngomugqa wokugoqekile oqhubekayo. Ijubane lokuhamba lomuchilo wensimbi engagqwali emgqeni licishe libe ngu-60m ~ 80m/min. Ngemva kwalesi sinyathelo, ukuphela kobuso kuzoba ngamahora amabili okugoqekile okukhanyayo.

Inombolo 4: Ubuso beNombolo 4 buyisiphetho sobuso esicwebezelayo esicwebezelayo esikhanya kakhulu kunobuso beNombolo 3. Butholakala nangokupholisha ipuleti lensimbi engagqwali eligoqwe ngokubandayo elinobuso obungu-2 D noma obungu-2 B njengesisekelo bese upholisha ngebhande elinobukhulu obungu-150-180# Ubuso obufakwe ngomshini. Ubulukhuni bobuso Inani le-Ra elilinganiswa yithuluzi lingu-0.2 ~ 1.5μm. Ubuso beNombolo 4 busetshenziswa kabanzi emishinini yokudlela nasekhishini, imishini yezokwelapha, imihlobiso yezakhiwo, izitsha, njll.

I-HL: Ubuso be-HL buvame ukubizwa ngokuthi ukuphela kwezinwele. Izinga le-JIS laseJapan libeka ukuthi ibhande elinobukhulu obungu-150-240# lisetshenziselwa ukupholisha ubuso obunobukhulu obufana nobezinwele obutholakalayo. Ezingeni le-GB3280 laseShayina, imithetho ayicacile. Ukuphela kwezinwele ze-HL kusetshenziselwa kakhulu ukuhlobisa izakhiwo njengezinyusi, izitebhisi, kanye nama-facade.

No.6: Ubuso beNombolo 6 busekelwe ebusweni beNombolo 4 futhi bupholishwa ngebhulashi leTampico noma izinto ezihudulayo ezinosayizi wezinhlayiya ze-W63 ezichazwe yi-GB2477 standard. Lobu buso bunokukhanya okuhle kwensimbi nokusebenza okuthambile. Ukukhanya kubuthakathaka futhi akubonisi isithombe. Ngenxa yalesi sici esihle, kufanelekile kakhulu ukwenza izindonga zamakhethini esakhiwo kanye nemihlobiso yemiphetho yesakhiwo, futhi isetshenziswa kabanzi njengezitsha zasekhishini.

I-BA: I-BA iwubuso obutholakala ngokwelashwa kokushisa okukhanyayo ngemva kokugoqa okubandayo. Ukwelashwa kokushisa okukhanyayo kuwukunamathela ngaphansi komkhathi ovikelayo oqinisekisa ukuthi ubuso abukhiqizwanga ukuze kulondolozwe ukukhanya kobuso obugoqa okubandayo, bese usebenzisa i-roll yokushelela enembile kakhulu ukuze kulinganiswe ukukhanya ukuze kuthuthukiswe ukukhanya kobuso. Lobu buso buseduze nokuqedwa kwesibuko, futhi ubulukhuni bobuso Inani le-Ra elilinganiswa yithuluzi lingu-0.05-0.1μm. Ubuso be-BA bunokusetshenziswa okubanzi futhi bungasetshenziswa njengezitsha zasekhishini, izinto zasekhaya, imishini yezokwelapha, izingxenye zezimoto kanye nemihlobiso.

Inombolo 8: Inombolo 8 iyindawo eqediwe ngesibuko enokukhanya okuphezulu kakhulu ngaphandle kwezinhlayiya ezirhabaxa. Imboni yokucubungula okujulile kwensimbi engagqwali nayo ibiza amapuleti angu-8K. Ngokuvamile, izinto ze-BA zisetshenziswa njengezinto zokusetshenziswa zokuqeda isibuko ngokugaya nokupholisha kuphela. Ngemva kokuqeda isibuko, indawo iwubuciko, ngakho-ke isetshenziswa kakhulu ekuhlobiseni indawo yokungena esakhiweni kanye nasekuhlobiseni ingaphakathi.

Inqubo yokukhiqiza ikhoyili yensimbi engagqwali yile: ukulungiswa kwezinto zokusetshenziswa - ukunamathisela kanye nokukha - (ukugaya okuphakathi) - ukugoqa - ukukha - ukukha - ukukha - ukulinganisa (ukugaya nokupholisha umkhiqizo okuqediwe) - ukusika, ukupakisha kanye nokugcina.

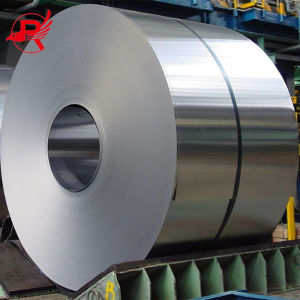

ukupakishwa olwandle okujwayelekile kwekhoyili yensimbi engagqwali

Ukupakisha olwandle okujwayelekile kokuthumela ngaphandle:

Iphepha Elingangeni Manzi + Ifilimu ye-PVC + Ibhande Lebhande + Iphalethi Lokhuni noma Ikesi Lokhuni;

Ukupakishwa okwenziwe ngokwezifiso njengesicelo sakho (Ilogo noma okunye okuqukethwe kuyamukelwa ukuthi kuphrintwe ephaketheni);

Okunye ukupakisha okukhethekile kuzoklanywa njengesicelo sekhasimende;

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.