Ishubhu Lensimbi Eyisikwele Eyenziwe Ngogesi Ngosayizi Ohlukahlukene

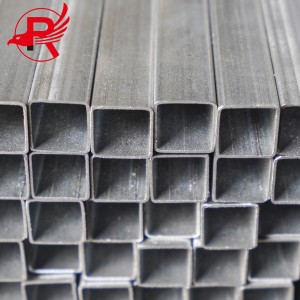

Ipayipi lesikwele elihlanganisiweuhlobo lwepayipi lensimbi eliyisikwele eliyisikwele elinomumo nosayizi wesigaba esiyisikwele elenziwe ngensimbi egoqwe ngokushisa noma ebandayo egoqwe ngogesi noma ikhoyili egoqwe ngogesi njengengenalutho ngokusebenzisa ukugoba okubandayo bese kuba ngokusebenzisa ukushisela okuvama kakhulu, noma ipayipi lensimbi eliyindilinga elenziwe ngokubandayo elenziwe kusengaphambili bese kuba ngepayipi eliyisikwele eligoqwe ngogesi elishisayo.

Ipayipi lesikwele elihlanganisiwe livame ukusetshenziswa ekwakheni, kwezobunjiniyela kanye nasezindaweni zokusebenza zezimboni ngenxa yokuqina kwalo kanye nokumelana nokugqwala. Okulandelayo eminye imininingwane ejwayelekile yepayipi lesikwele elihlanganisiwe:

Izinto: Ipayipi lensimbi eliyisikwele elihlanganisiwe livame ukwenziwa ngensimbi futhi limbozwe ngengqimba ye-zinc ukuvimbela ukugqwala.

Usayizi: Usayizi weshubhu lensimbi eliyisikwele elihlanganisiwe uyahlukahluka kakhulu, kodwa osayizi abavamile bangama-intshi angu-1/2, ama-intshi angu-3/4, ama-intshi angu-1, ama-intshi angu-1-1/4, ama-intshi angu-1-1/2, ama-intshi angu-2, njll. Ubukhulu obuhlukahlukene bodonga.

Ukwelashwa kwendawo: Ukwembozwa nge-galvanized kunikeza ipayipi eliyisikwele ukubukeka kwesiliva okucwebezelayo futhi kunikeza ungqimba oluvikelayo ekugqwaleni nasekugqwaleni.

Amandla kanye nomthamo wokuthwala umthwalo: Ipayipi lesikwele elihlanganisiwe laziwa ngamandla alo aphezulu kanye nomthamo wokuthwala umthwalo, okwenza lifaneleke ukusetshenziswa kwezakhiwo ezifana nemishayo yokusekela, ozimele, kanye namakholomu.

Ukushisela kanye nokwakhiwa: Ipayipi lesikwele elihlanganisiwe lingashiselwa kalula futhi lenziwe ukuze kwakhiwe izakhiwo nezingxenye ezenziwe ngokwezifiso.

Isicelo: Ipayipi lesikwele elihlanganisiwe livame ukusetshenziswa ekwakheni, ezicingweni, ezinsikeni, efenisha yangaphandle kanye nezicelo ezahlukahlukene zezimboni.

1. Ukumelana nokugqwala: I-Galvanizing iyindlela yokuvimbela ukugqwala engabizi futhi ephumelelayo evame ukusetshenziswa. Cishe ingxenye yomkhiqizo we-zinc emhlabeni isetshenziswa kule nqubo. I-zinc ayigcini nje ngokwakha ungqimba oluqinile lokuvikela phezu kwensimbi, kodwa futhi inomphumela wokuvikela i-cathodic. Lapho ungqimba lwe-zinc lonakele, lusengavimbela ukugqwala kwezinto eziyisisekelo sensimbi ngokuvikela i-cathodic.

2. Ukusebenza kahle kokugoba nokubanda kanye nokushisela: kusetshenziswa kakhulu izinga eliphansi lensimbi yekhabhoni, izidingo zinokusebenza okuhle kokugoba nokubanda kanye nokushisela, kanye nokusebenza okuthile kokunyathela

3. Ukukhanya: Kukhanya kakhulu, okwenza kube yisithiyo ekushiseni

4. Ukuqina kwesembozo kuqinile, ungqimba oluhlanganisiwe lwakha isakhiwo esikhethekile sensimbi, lesi sakhiwo singamelana nomonakalo womshini ekuthuthweni nasekusetshenzisweni.

5. Ukwelashwa kwendawo: Ukwembozwa nge-galvanized kunikeza ipayipi eliyisikwele ukubukeka kwesiliva okukhazimulayo futhi kunikeza ungqimba oluvikelayo ekugqwaleni nasekugqwaleni.

6. Amandla kanye nomthamo wokuthwala imithwalo:Ipayipi Elikhulu Lesikwele Eligayiweyaziwa ngamandla ayo aphezulu kanye nomthamo wayo wokuthwala imithwalo, okwenza ifaneleke ukusetshenziswa kwezakhiwo ezifana nemishayo yokusekela, ozimele, kanye namakholomu.

7. Ukushisela kanye nokukhiqiza:Ipayipi Lesikwele Sensimbi Egqinsiwe ye-Q235ingashintshwa kalula futhi yenziwe ukuze kudalwe izakhiwo nezingxenye ezenziwe ngokwezifiso.

Ukusetshenziswa kwepayipi lensimbi elenziwe nge-galvanized kubanzi kakhulu, kusetshenziswa kakhulu ezindaweni ezilandelayo:

1. Amasimu okwakha nokwakha: Amapayipi ensimbi agqitshwe nge-galvanized angasetshenziswa ezakhiweni zokusekela ukwakha, izinhlelo zamapayipi angaphakathi nangaphandle, izitebhisi kanye nezinsika kanye nezinye izinjongo zesakhiwo sokwakha.

2. Insimu Yezokuthutha: Ipayipi lensimbi elihlanganisiwe lingasetshenziswa ukukhiqiza izingxenye zezimoto zokuthutha, njengepayipi lokukhipha umoya emotweni, ozimele bezithuthuthu, njll.

3. Emkhakheni wobunjiniyela bamandla: ipayipi lensimbi elenziwe nge-galvanized lingasetshenziswa ezisekelweni zemigqa, amashubhu ekhebula, amakhabethe okulawula nokunye kubunjiniyela bamandla.

4. Insimu yokuhlola uwoyela negesi: Ipayipi lensimbi elihlanganisiwe lingasetshenziswa ezinhlelweni zamapayipi, ezakhiweni zemithombo kanye nokugcinwa kwegesi ekuhlolweni uwoyela negesi.

5. Insimu Yezolimo: Ipayipi lensimbi elihlanganisiwe lingasetshenziswa ekuniseleni insimu yezolimo, ukusekela insimu yezithelo, njll.

| Okujwayelekile | I-JIS G3302 1998, i-ASTM A653M/A924M 2004, konke ngokwesicelo sekhasimende |

| Ubukhulu | kusukela ku-0.12mm kuya ku-4.0mm, konke kuyatholakala |

| Ububanzi | kusukela ku-600mm kuya ku-1250mm, konke kuyatholakala |

| isisindo | kusukela ku-2-10MT, ngokwesicelo sekhasimende |

| Isisindo sokumboza se-Zinc | 40g/m2-275g/m2, uhlangothi oluphindwe kabili |

| I-Spangle | i-span enkulu, i-span evamile, i-span encane, okungeyona i-span |

| Ukwelashwa kwendawo | Ukwelashwa kwendawo |

| Umphetho | umphetho wokugaya, umphetho osikiwe |

| I-MOQ | I-oda elincane lokuhlola ithani eli-10 ubukhulu ngabunye, 1x20' ngokulethwa ngakunye |

| Ukuqeda kobuso | Iphethini | Isicelo |

| I-spangle evamile | Ama-spangle ajwayelekile anephethini yezimbali | Ukusetshenziswa okuvamile |

| Ama-spangle ancishisiwe kunokuvamile | Ama-spangle ancishisiwe kunokuvamile | Izicelo zokupenda ezijwayelekile |

| Okungeyona i-spangle | Ama-spangle ancishiswe kakhulu | Izicelo zokupenda ezikhethekile |

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.