-

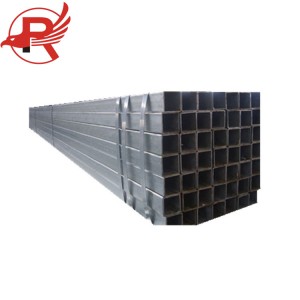

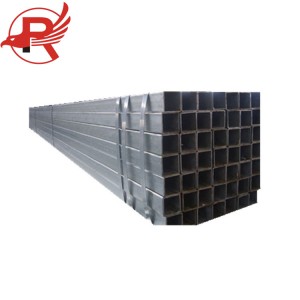

Izinto zokwakha zokwakha zebanga B 8 INCH Insimbi Ephansi Enekhabhoni Ephansi Ipayipi Lensimbi Egayiwe ye-GI

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

-

Ipayipi Lensimbi Eyindilinga Ehlanganisiwe Yesigaba Esingenalutho

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

-

Ipayipi Lensimbi Eliyindilinga Le-EN10219 / BS1387 Elishisayo Eligayiwe Le-ERW

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

-

Ipayipi Lensimbi Ecwebezelwe Ngokushisa Elicwiliswe Nge-Scaffolding Tube

I-hot-dip galvanization iwuhlobo lwe-galvanization. Inqubo yokumboza insimbi nensimbi nge-zinc, ehlanganisa ubuso bensimbi eyisisekelo lapho ifaka insimbi ebhavini le-zinc encibilikisiwe ekushiseni okungaba ngu-450 °C (842 °F).

-

Ipayipi le-GI Pipe Cold Rolled Q215a Pre-Galvanized Welded Steel Tube

I-hot-dip galvanization iwuhlobo lwe-galvanization. Inqubo yokumboza insimbi nensimbi nge-zinc, ehlanganisa ubuso bensimbi eyisisekelo lapho ifaka insimbi ebhavini le-zinc encibilikisiwe ekushiseni okungaba ngu-450 °C (842 °F).

-

I-China Supply Q195 Low Carbon Square Galvanized Steel Tube & Pipe

Ipayipi lesikwele elihlanganisiweuhlobo lwepayipi lensimbi eliyisikwele eliyisikwele eliyisikwele elinomumo nosayizi wesigaba esiyisikwele elenziwe ngensimbi egoqwe ngokushisa noma ebandayo egoqwe ngogesi noma ikhoyili egoqwe ngogesi njengengenalutho ngokucubungula okubandayo bese kuba nge-welding evame kakhulu, noma ipayipi lensimbi eliyisikwele elenziwe ngokubandayo elenziwe kusengaphambili bese kuba ngepayipi eliyisikwele eligoqwe ngogesi elishisayo.

-

Amapayipi Ashisayo Acwiliswe GB/T 700:2006 Q195 Q235 Ipayipi Elifushane Lensimbi Eyisikwele Egayiwe

Ipayipi lesikwele elihlanganisiweuhlobo lwepayipi lensimbi eliyisikwele eliyisikwele elinomumo nosayizi wesigaba esiyisikwele elenziwe ngensimbi egoqwe ngokushisa noma ebandayo egoqwe ngogesi noma ikhoyili egoqwe ngogesi njengengenalutho ngokusebenzisa ukugoba okubandayo bese kuba ngokusebenzisa ukushisela okuvama kakhulu, noma ipayipi lensimbi eliyindilinga elenziwe ngokubandayo elenziwe kusengaphambili bese kuba ngepayipi eliyisikwele eligoqwe ngogesi elishisayo.

-

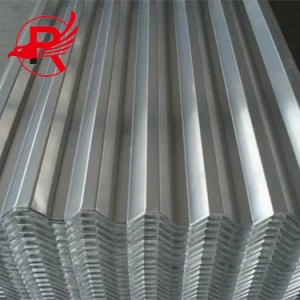

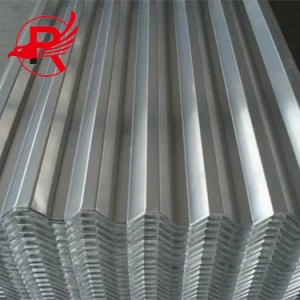

Imikhiqizo Eshisayo Ibhodi Elihlanganisiwe Lombala Ohlanganisiwe le-DX51D PPGI Lokwakha Uphahla

Enye yezimpawu eziyinhloko zeishidi elihlanganisiweukumelana nokugqwala. Ngesikhathi senqubo yokukhiqizwa kwamashidi agqitshiwe, ungqimba lwe-zinc lufakwa phezu kwe-substrate yensimbi ukuze kwakheke ifilimu evikelayo. Lokhu kungavimbela ngempumelelo ukugqwala kwe-oxidative okubangelwa ukuthintana ngqo kwe-substrate yensimbi nomoya namanzi.

-

Ifektri engu-2×2 ehlanganisiwe ene-Hollow Section 14 Gauge Tubing Iron Square Steel Pipes

Ipayipi lensimbi elifakwe igesi elishisayo lisetshenziswa kabanzi ekwakheni, emishinini, emayini yamalahle, embonini yamakhemikhali, kumandla kagesi, ezimotweni zesitimela, embonini yezimoto, emigwaqweni emikhulu, emabhuloho, ezitsheni, ezindaweni zemidlalo, emishinini yezolimo, emishinini kaphethiloli, emishinini yokuhlola, ekwakhiweni kwezindawo zokugcina izithombo kanye nakwezinye izimboni zokukhiqiza.

-

Ipayipi Lensimbi Eyisikwele Eshisayo Eyindilinga Eshisayo

Ipayipi elihlanganisiweibhekisela epayipini elingaphezulu kwalo limbozwe ungqimba lwe-zinc ngendlela yokucwilisa eshisayo. Ngenxa yokuthi i-zinc inokumelana okuqinile kokugqwala nokugqwala, amapayipi e-galvanized asetshenziswa kabanzi ezinhlelweni zamapayipi ekwakheni, ekuthuthweni, ekusetshenzisweni kwensimbi nakwezinye izinkambu.

-

Ipayipi Eligayiwe Le-Q235/Q195/Q345/A36 Elishisayo Le-DIP Galvanized

Ipayipi elihlanganisiweinokwakheka okuqinile, okwenza ibe yinhle kakhulu ezimweni lapho idinga ukumelana nengcindezi ethile. Ubuso bepayipi elihlanganisiwe bubushelelezi futhi abuthambekele ekuqongeleleni kwezikali, okwenza kube nzima kakhulu ukuguguleka ngesikhathi sokusetshenziswa isikhathi eside.

-

Umhlinzeki waseShayina Ipayipi Lensimbi Elishisayo Le-DIP Lashukumisayo

Ipayipi lokugaya elishisayoIphendula insimbi encibilikisiwe nge-matrix yensimbi ukuze ikhiqize ungqimba lwe-alloy, ngaleyo ndlela ihlanganise i-matrix kanye ne-coating. I-hot-dip galvanizing iwuku-pickle ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuyi-pickle, ihlanzwa ngesisombululo samanzi se-ammonium chloride noma i-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride kanye ne-zinc chloride, bese ithunyelwa ethangini lokufaka i-hot dip.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur