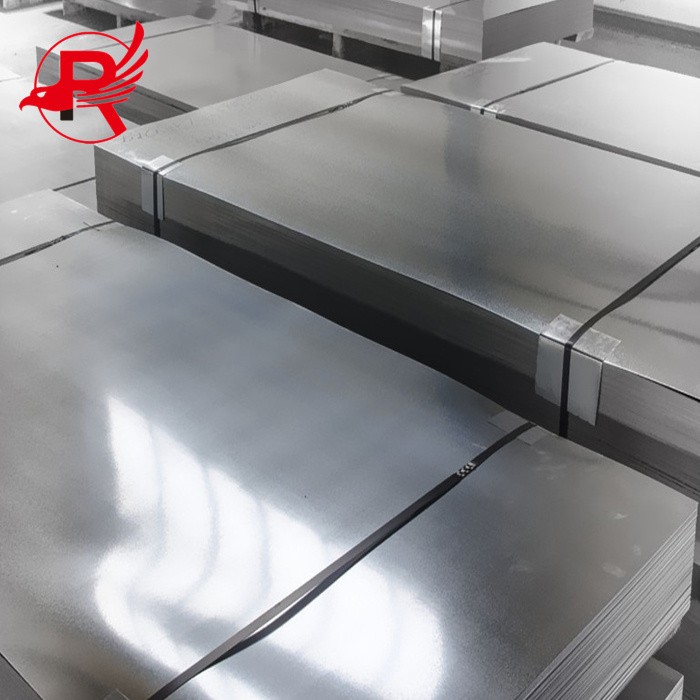

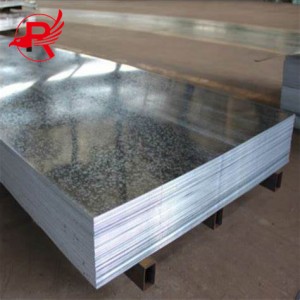

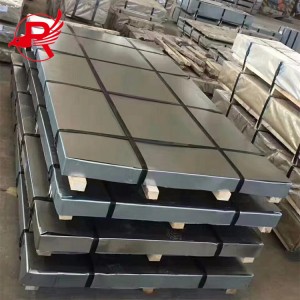

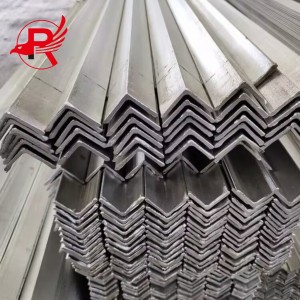

Izinto Zokwakha Ezisezingeni Eliphezulu 0.12-4.0mm SPCC Cold Rolled Galvanized Steel Sheet

Kunemininingwane ethile okudingeka inakwe lapho usebenzisa amashidi e-galvanized. Okokuqala, ngesikhathi sokuthuthwa nokugcinwa, ukushayisana nokungqubuzana kufanele kugwenywe ukuze kugwenywe umonakalo kungqimba ye-galvanized. Okwesibili, ngesikhathi sokufakwa nokucubungula, amathuluzi nezindlela ezifanele kufanele zikhethwe ukuze kugwenywe ukuklwebheka nokulimaza ungqimba lwe-galvanized. Ngaphezu kwalokho, ngesikhathi sokusetshenziswa, amashidi e-galvanized kufanele ahlanzwe futhi agcinwe njalo, futhi ukungcola nokungcola okungaphezulu kufanele kususwe ngesikhathi ukuze kugcinwe ukubukeka nokusebenza kahle. Ngaphezu kwalokho, kufanele kuthathwe ukunakekelwa ukuze kugwenywe ukuthintana namakhemikhali anjenge-acids nama-alkali ukuze kugwenywe ukuthinta ukumelana nokugqwala kwamashidi e-galvanized. Okokugcina, kufanele kuthathwe ukunakekelwa ukuze kugwenywe ukusetshenziswa ezindaweni ezishisa kakhulu ukuze kugwenywe ukuthinta ukusebenza kwengqimba ye-galvanized. Ngokuvamile, ukusetshenziswa nokugcinwa okufanele kuyisihluthulelo sokuqinisekisa ukusebenza okuzinzile kwesikhathi eside kwamashidi e-galvanized. Ukusetshenziswa nokugcinwa okunengqondo kungandisa impilo yesevisi yamashidi e-galvanized futhi kuqinisekise imiphumela yokusetshenziswa kwawo emikhakheni ehlukahlukene.

Ishidi elihlanganisiwezinezinzuzo eziningana ezenza zisetshenziswe kabanzi emikhakheni eyahlukahlukene. Okokuqala, amashidi e-galvanized anokumelana okuhle kakhulu nokugqwala. Ingqimba ye-galvanized ingavimbela ngempumelelo ubuso bensimbi ukuthi bungagqwali umkhathi, amanzi kanye nezinto zamakhemikhali, ngaleyo ndlela yandise impilo yensimbi. Okwesibili, amashidi e-galvanized anokumelana okuhle nokugqwala futhi afaneleka ezindaweni ezidinga ukumelana nokungqubuzana nokugqwala, njengezakhiwo zokwakha, imishini yemishini kanye nezinye izinsimu. Ngaphezu kwalokho,Ipuleti Lensimbi Elishisayo Eligayiwefuthi zinezakhiwo ezinhle zokucubungula futhi zingacutshungulwa ngokugoba, ukunyathela, ukushisela, njll., futhi zifanele ukukhiqiza izimo ezahlukahlukene eziyinkimbinkimbi. Ngaphezu kwalokho, ubuso be-Ishidi Lensimbi Eligayiweibushelelezi futhi iyinhle, futhi ingasetshenziswa ngqo njengezinto zokuhlobisa. Ngaphezu kwalokho, amashidi e-galvanized nawo anokuqhutshwa kahle kukagesi futhi afanelekela amandla kagesi, ukuxhumana kanye neminye imikhakha. Ngokuvamile, amashidi e-galvanized abe ngenye yezinto ezibalulekile ekwakheni, emishinini, kagesi, ukuxhumana kanye neminye imikhakha ngenxa yokumelana kwawo nokugqwala, ukumelana nokuguguleka kanye nokusebenza kahle kokucubungula.

Ipuleti Lensimbi Elakhiwe Nge-Galvanizedzisetshenziswa kabanzi emikhakheni eyahlukene. Okokuqala, emkhakheni wokwakha, amashidi e-galvanized avame ukusetshenziswa ezinhlelweni zokusekela kanye nokukhipha amanzi ezakhiweni zokwakha. Angasetshenziswa ozimele bokwakha, izikhonkwane zezitebhisi, izinsimbi zokubiyela nezinye izingxenye, futhi angasetshenziswa njengento eyinhloko yamapayipi okukhipha amanzi ngoba ukumelana kwawo nokugqwala kungandisa ngempumelelo impilo yawo yokusebenza. Okwesibili, emkhakheni wezimboni, amashidi e-galvanized avame ukusetshenziswa ukukhiqiza imishini nezingxenye ezahlukahlukene, njengamathangi okugcina, amapayipi, amafeni, imishini yokuthutha, njll. Ukumelana nokugqwala kwamashidi e-galvanized kwenza ukusetshenziswa kwesikhathi eside ezindaweni ezinzima zezimboni, okuqinisekisa ukusebenza okuphephile kwemishini. Ngaphezu kwalokho, emkhakheni wezolimo, amashidi e-galvanized nawo anezinhlelo ezibalulekile. Angasetshenziswa ezinhlelweni zokunisela epulazini, izakhiwo zokusekela imishini yezolimo, njll. ngoba ukumelana kwawo nokugqwala kungamelana nokuguguleka kwemishini ngamakhemikhali enhlabathini. Ngaphezu kwalokho, emkhakheni wezokuthutha, amashidi e-galvanized avame ukusetshenziswa ukukhiqiza izingxenye zezimoto, izingxenye zemikhumbi, njll., ngoba ukumelana kwawo nokugqwala kungandisa impilo yokusebenza kwezimoto zokuthutha. Ngokuvamile, amashidi e-galvanized anezicelo ezibalulekile ekwakheni, embonini, kwezolimo, kwezokuthutha nakweminye imikhakha, futhi ukumelana kwawo nokugqwala kuwenza abe ngenye yezinto ezifanelekile zemishini nezakhiwo ezahlukahlukene.

| Izinga Lobuchwepheshe | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga Lensimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); noma kwamakhasimende Isidingo |

| Ubukhulu | imfuneko yekhasimende |

| Ububanzi | ngokwezidingo zekhasimende |

| Uhlobo Lokumboza | Insimbi Eshisayo Ecwiliswe Ngogesi (HDGI) |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa (C), Ukufaka uwoyela (O), Ukuvala i-Lacquer (L), Ukuphosphating (P), Okungaphathwanga (U) |

| Isakhiwo Somphezulu | Ukugqoka okujwayelekile kwe-spangle (NS), ukugqoka okuncishisiwe kwe-spangle (MS), okungena-spangle (FS) |

| Ikhwalithi | Kuvunywe yi-SGS, ISO |

| ID | 508mm/610mm |

| Isisindo sekhoyili | I-metric ton engu-3-20 nge-coil ngayinye |

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Imakethe yokuthumela ngaphandle | IYurophu, i-Afrika, i-Asia Ephakathi, iNingizimu-mpumalanga ye-Asia, iMpumalanga Ephakathi, iNingizimu Melika, iNyakatho Melika, njll. |

| Ithebula Lokuqhathanisa Ubukhulu Begeji | ||||

| Igeyiji | Okuncane | I-Aluminium | I-Galvanised | Insimbi Engagqwali |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.