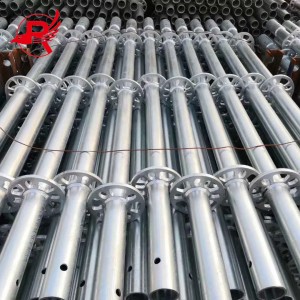

Ipayipi Lensimbi Eshisayo Elakhiwe Nge-DIP

Njengento enhle kakhulu yepayipi lensimbi, ipayipi elihlanganisiwe linezindlela eziningi zokusetshenziswa. Ekusetshenzisweni kwangempela, uhlobo olufanele kanye nencazelo yepayipi elihlanganisiwe kufanele kukhethwe ngokwesimo esithile, futhi kufakwe futhi kugcinwe ngokuhambisana ngokuqinile nezindinganiso kanye nemininingwane efanele ukuqinisekisa ukusebenza okuphephile nokuzinzile kwepayipi.

Izici

Isici esibaluleke kakhulu sepayipi elihlanganisiwe ukusebenza kwalo okuhle kakhulu kokulwa nokugqwala. Ukuba khona kwengqimba ye-zinc kuhlukanisa ipayipi lensimbi ekuthinteni umhlaba wangaphandle futhi kuvimbela ukugqwala nokugqwala kwepayipi lensimbi. Lesi sici senza ipayipi elihlanganisiwe lizinze ezindaweni ezahlukahlukene ezigqwala.

Isicelo

Ipayipi elihlanganisiwe lihlala isikhathi eside ngenxa yokuvikelwa kwengqimba ye-zinc. Ngisho nangaphansi kwezimo zemvelo ezinzima, njengomswakama, izinga lokushisa eliphezulu, izinga lokushisa eliphansi, njll., amapayipi ahlanganisiwe angagcina ukusebenza kwawo kwasekuqaleni kanye nokubukeka kwawo.

Amapharamitha

| Igama lomkhiqizo | Ipayipi Elihlanganisiwe |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njll. |

| Ubude | I-standard 6m kanye ne-12m noma njengemfuneko yamakhasimende |

| Ububanzi | 600mm-1500mm, ngokwezidingo zamakhasimende |

| Ezobuchwepheshe | I-Hot Cwilisa Lashukumisaipayipi |

| Isimbozo seZinc | 30-275g/m2 |

| Isicelo | Kusetshenziswa kabanzi ezakhiweni ezahlukene zezakhiwo, amabhuloho, izimoto, ama-bracker, imishini njll. |

Imininingwane

Izendlalelo ze-zinc zingakhiqizwa kusukela ku-30g kuya ku-550g futhi zinganikezwa nge-hotdip galvanizing, i-electric galvanizing kanye ne-pre-galvanizing. Inikeza isendlalelo sokusekela ukukhiqizwa kwe-zinc ngemva kombiko wokuhlola. Ubukhulu bukhiqizwa ngokuhambisana nenkontileka. Inqubo yenkampani yethu ukubekezelela ubukhulu kungaphakathi kuka-±0.01mm. Izendlalelo ze-zinc zingakhiqizwa kusukela ku-30g kuya ku-550g futhi zinganikezwa nge-hotdip galvanizing, i-electric galvanizing kanye ne-galvanizing. Inikeza isendlalelo sokusekela ukukhiqizwa kwe-zinc ngemva kombiko wokuhlola. Ubukhulu bukhiqizwa ngokuhambisana nenkontileka. Inqubo yenkampani yethu ukubekezelela ubukhulu kungaphakathi kuka-±0.01mm. I-laser cutting nozzle, i-nozzle ibushelelezi futhi icocekile. Ipayipi elihlanganisiwe eliqondile, ubuso obuhlanganisiwe. Isika ubude kusukela kumamitha angu-6-12, singanikeza ubude obujwayelekile baseMelika obungu-20ft 40ft. Noma singavula isikhunta ukuze senze ngokwezifiso ubude bomkhiqizo, njenge-13 metres njll. 50.000m warehouse. Ikhiqiza okungaphezu kwalokho Amathani angu-5,000 ezimpahla ngosuku. Ngakho-ke singabanikeza isikhathi sokuthumela esisheshayo kanye nentengo yokuncintisana.

Ipayipi elihlanganisiwe liyinto yokwakha evamile futhi lisetshenziswa ngezindlela eziningi. Enkambisweni yokuthunyelwa, ngenxa yethonya lezici zemvelo, kulula ukubangela izinkinga ezifana nokugqwala, ukuguquka noma ukulimala kwepayipi lensimbi, ngakho-ke kubaluleke kakhulu ekupakisheni nasekuthuthweni kwamapayipi ahlanganisiwe. Leli phepha lizokwethula indlela yokupakisha ipayipi elihlanganisiwe enkambisweni yokuthunyelwa.

2. Izidingo zokupakisha

1. Ubuso bepayipi lensimbi kufanele buhlanzeke futhi bome, futhi akufanele kube khona amafutha, uthuli kanye nezinye izinsalela.

2. Ipayipi lensimbi kumele lifakwe iphepha elimbozwe ngepulasitiki elinezingqimba ezimbili, ungqimba lwangaphandle lumbozwe ngephepha lepulasitiki elinobukhulu obungaphansi kuka-0.5mm, kanti ungqimba lwangaphakathi lumbozwe ngefilimu yepulasitiki ye-polyethylene esobala enobukhulu obungaphansi kuka-0.02mm.

3. Ipayipi lensimbi kumele limakwe ngemva kokupakisha, futhi uphawu kufanele lufake uhlobo, imininingwane, inombolo yebhetshi kanye nosuku lokukhiqizwa kwepayipi lensimbi.

4. Ipayipi lensimbi kufanele lihlukaniswe futhi lipakishwe ngokwezigaba ezahlukene njengezincazelo, usayizi nobude ukuze kube lula ukulayisha nokukhipha impahla kanye nokugcina impahla.

Okwesithathu, indlela yokupakisha

1. Ngaphambi kokupakisha ipayipi elifakwe i-galvanized, ubuso bepayipi kufanele buhlanzwe futhi buphathwe ukuze kuqinisekiswe ukuthi ubuso buhlanzekile futhi bomile, ukuze kugwenywe izinkinga ezifana nokugqwala kwepayipi lensimbi ngesikhathi sokuthunyelwa.

2. Lapho kufakwa amapayipi agqitshwe nge-galvanized, kufanele kuqashelwe ukuvikelwa kwamapayipi ensimbi, kanye nokusetshenziswa kwe-red cork splints ukuqinisa zombili iziphetho zamapayipi ensimbi ukuvimbela ukuguquka nokulimala ngesikhathi sokupakisha nokuthuthwa.

3. Izinto zokupakisha zepayipi elihlanganisiwe kumele zibe nomphumela wokumelana nomswakama, ukumelana namanzi kanye nokugqwala ukuqinisekisa ukuthi ipayipi lensimbi alithintwa umswakama noma ukugqwala ngesikhathi senqubo yokuthumela.

4. Ngemva kokuba ipayipi elihlanganisiwe selipakishiwe, naka i-sunscreen engangeni umswakama kanye ne-sunscreen ukuze ugweme ukuchayeka isikhathi eside elangeni noma endaweni enomswakama.

4. Izinyathelo Zokuqapha

1. Ukupakishwa kwamapayipi agqitshwe nge-galvanized kumele kunake ukulinganiswa kosayizi nobude ukuze kugwenywe imfucuza nokulahleka okubangelwa ukungalingani kosayizi.

2. Ngemva kokupakishwa kwepayipi elihlanganisiwe, kuyadingeka ukulimaka nokulihlukanisa ngesikhathi ukuze kube lula ukuphatha kanye nokugcina impahla.

3, ukupakishwa kwamapayipi agqitshiwe, kufanele kunake ukuphakama nokuqina kokupakishwa kwezimpahla, ukugwema ukuthambekela kwezimpahla noma ukupakishwa okuphezulu kakhulu okungabangela umonakalo ezimpahleni.

Lokhu okungenhla kuyindlela yokufaka ipayipi elihlanganisiwe enqubweni yokuthumela, okuhlanganisa nezidingo zokufaka, izindlela zokufaka kanye nezinyathelo zokuphepha. Lapho ufaka futhi uthutha, kuyadingeka ukusebenza ngokuhambisana nemithethonqubo, futhi uvikele ngempumelelo ipayipi lensimbi ukuqinisekisa ukufika okuphephile kwezimpahla endaweni oya kuyo.

1. Angakanani amanani akho?

Amanani ethu angashintsha kuye ngokuthi ukunikezwa kwempahla kuyatholakala yini kanye nezinye izici zemakethe. Sizokuthumelela uhlu lwamanani olubuyekeziwe ngemuva kokuxhumana nenkampani yakho.

nathi ukuze uthole ulwazi olwengeziwe.

2. Ingabe unenani elincane kakhulu le-oda?

Yebo, sidinga ukuthi wonke ama-oda aphesheya abe nenani elincane eliqhubekayo le-oda. Uma ufuna ukuthengisa kabusha kodwa ngamanani amancane kakhulu, sincoma ukuthi uhlole iwebhusayithi yethu.

3. Ungakwazi yini ukunikeza amadokhumenti afanele?

Yebo, singanikeza imibhalo eminingi kufaka phakathi Izitifiketi Zokuhlaziya/Ukuhambisana; Umshwalense; Umsuka, kanye neminye imibhalo yokuthumela ngaphandle lapho kudingeka khona.

4. Singakanani isikhathi esimaphakathi sokuhola?

Kumasampula, isikhathi sokuhola cishe siyizinsuku eziyi-7. Ekukhiqizweni ngobuningi, isikhathi sokuhola siyizinsuku ezi-5-20 ngemuva kokuthola inkokhelo yediphozithi. Izikhathi zokuhola ziqala ukusebenza uma

(1) sesiyitholile idiphozithi yakho, futhi (2) sinemvume yakho yokugcina yemikhiqizo yakho. Uma izikhathi zethu zokukhokha zingasebenzi ngesikhathi sakho sokugcina, sicela ubuyekeze izidingo zakho ngokuthengisa kwakho. Kuzo zonke izimo sizozama ukuhlangabezana nezidingo zakho. Ezimweni eziningi siyakwazi ukwenza kanjalo.

5. Yiziphi izinhlobo zezindlela zokukhokha ozamukelayo?

U-30% kusengaphambili nge-T/T, u-70% uzoba ngaphambi kokuthunyelwa okuyisisekelo ku-FOB; u-30% kusengaphambili nge-T/T, u-70% uma kuqhathaniswa nekhophi ye-BL eyisisekelo ku-CIF.