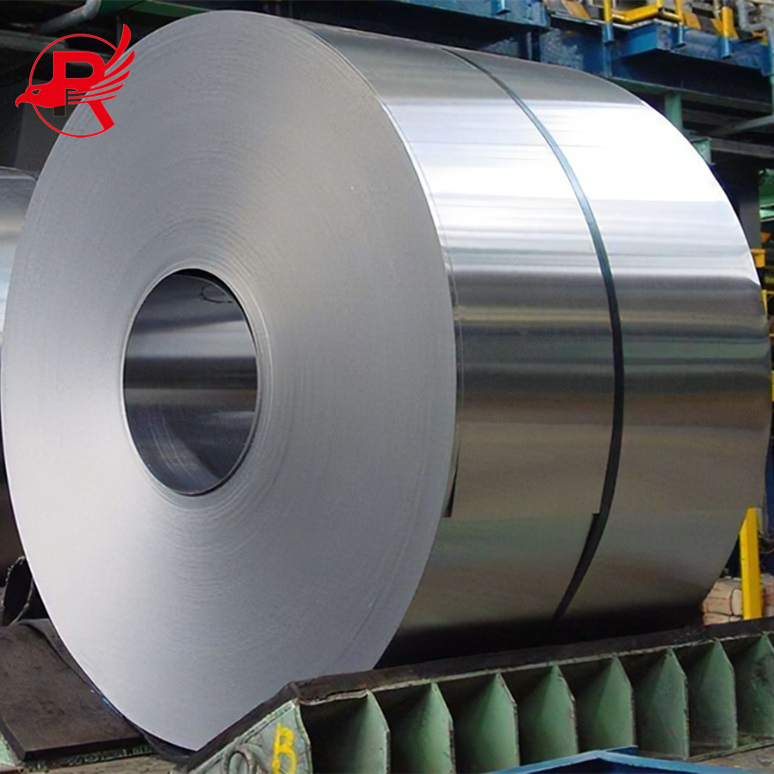

I-Hot Rolled Aisi 309 310 310S 321 Ikhoyili Yensimbi Engagqwali

| Igama Lomkhiqizo | Ikhoyili yensimbi engagqwali engu-309 310 310S 321 |

| Amabanga | 201/EN 1.4372/SUS201 |

| Ubulukhuni | 190-250HV |

| Ubukhulu | 0.02mm-6.0mm |

| Ububanzi | 1.0mm-1500mm |

| Umphetho | Isivalo/Isigayo |

| Ukubekezelela Ubuningi | ±10% |

| Ububanzi Bangaphakathi Be-Paper Core | Ingaphakathi lephepha elingu-Ø500mm, ingaphakathi elikhethekile lobubanzi futhi elingenalo ingaphakathi lephepha uma kucelwa ikhasimende |

| Ukuqedwa Komphezulu | I-NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror, njll. |

| Ukupakisha | Ikesi Lephalethi/Lokhuni |

| Imigomo Yokukhokha | Idiphozithi engu-30% TT kanye nebhalansi engu-70% ngaphambi kokuthunyelwa, i-100% LC lapho ibonwa |

| Isikhathi sokuthumela | Izinsuku zokusebenza eziyi-7-15 |

| I-MOQ | 200Kgs |

| Ichweba Lokuthumela | Ichweba laseShanghai/Ningbo |

| Isampula | Isampula yekhoyili yensimbi engagqwali engu-309 310 310S 321 iyatholakala |

I-201 iyinsimbi engagqwali enomsoco ophansi enikeza ukushibilika okuhle kakhulu, ukumelana okuhle nokugqwala kanye namandla aphezulu. Iyinto efanelekile yezinhlelo zokusebenza ezahlukahlukene okuhlanganisa imishini yokucubungula ukudla kanye nemishini yokucubungula amakhemikhali.

Okulandelayo uhlu lwezinye zezicelo ezivame kakhulu zamakhoyili ensimbi engagqwali:

1. Imishini Yokucubungula Ukudla kanye Nemishini Yokucubungula Amakhemikhali

2. Izimboni Zikawoyela Negesi

3. Izicelo Zasolwandle

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Izakhi Zamakhemikhali Zekhoyili Yensimbi Engagqwali

| Ukwakheka Kwamakhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngezindlela ezahlukene zokucubungula zokugoqa okubandayo kanye nokucubungula kabusha ubuso ngemva kokugoqa, ukuphela kobuso bezinsimbi zensimbi engagqwali kungaba nezinhlobo ezahlukene.

Insimbi engagqwali iyinto eguquguqukayo futhi eqinile esetshenziswa ezinhlotsheni eziningi zokusebenza, kusukela ezitsheni zasekhishini kuya ezintweni zokwakha. Ama-coil ensimbi engagqwali ayisici esibalulekile semikhiqizo eminingi njengoba enikeza indlela yokwenza le nto ibe yizimo nobukhulu obuthile. Ake sibheke kabanzi inqubo yokukhiqiza ama-coil ensimbi engagqwali.

1. Ukuncibilikisa nokucwenga: Isinyathelo sokuqala enqubweni yokukhiqiza ukuncibilikisa izinto zokusetshenziswa ezisetshenziselwa ukwenza insimbi engagqwali—ngokuvamile i-iron ore, i-nickel, i-chromium, nezinye izinsimbi. Lokhu kwenziwa esithandweni somlilo noma esithandweni somlilo, ngokuvamile kusetshenziswa i-arc kagesi noma isithando somlilo sokungenisa. Insimbi encibilikisiwe ephumayo iyacwengisiswa ukuze kususwe ukungcola futhi kuqinisekiswe ukwakheka okufanele kwe-alloy.

2. Ukuthunga: Ngemva kokuba insimbi isicwengisisiwe, ithululelwa ezikhumbeni ukuze kwakheke ama-billets aqoshiwe. I-slab ingaba nobukhulu obungamasentimitha ambalwa futhi inesisindo esingamathani angama-20 noma ngaphezulu. Le nqubo yokuthunga ivame ukwenziwa emshinini wokuthunga oqhubekayo, okuqinisekisa ukugeleza okuqhubekayo kwezinto kanye nokusebenza kahle okukhulu.

3. Ukugoqa okushisayo: I-slab iyashiswa bese idlula ochungechungeni lwemishini yokugoqa eshisayo. Imishini yokugoqa ifakwe imigoqo ecindezela futhi ibumbe insimbi ibe amashidi noma imichilo emincane. Inqubo yokugoqa okushisayo ingakhiqiza amazinga okushisa angaphezu kwama-degree Celsius ayi-1,000, okuvumela ukuthi izinto zibunjwe ngaphandle kokuphuka.

4. Ukugoqa okubandayo: Ngemva kokuba inqubo yokugoqa okushisayo isiqediwe, insimbi engagqwali ibe isigoqwa ebandayo ukuze kufezwe ukujiya okufiselekayo kanye nokuphela kwendawo. Lokhu kuhilela ukudlulisa izinto ochungechungeni lwemishini yokugoqa ebandayo, ecindezela futhi ibumbe insimbi. Ukugoqa okubandayo kwandisa amandla nokuqina kwensimbi engagqwali, okwenza iqine futhi iqine kakhudlwana.

5. Ukuhlanganisa: Uma insimbi engagqwali isibandisiwe yaze yaba ugqinsi olufunwayo, iyahlanganiswa ngesikhathi sokwelashwa kokushisa. Lokhu kuhilela ukufudumeza impahla kuze kufike ekushiseni okuphezulu bese iphola kancane ngokuhamba kwesikhathi. Ukuhlanganisa kusiza ukuthambisa insimbi engagqwali futhi kwandisa ukuqina kwayo, okwenza kube lula ukwakha ama-coil noma ezinye izimo.

6. Ukusikeka nokugoqa: Okokugcina, insimbi engagqwali ihlukaniswe yaba imichilo—isikwe yaba imichilo emincane—bese igoqwa ukuze ithunyelwe futhi igcinwe. Le nqubo ivame ukwenziwa kusetshenziswa imishini ekhethekile njengemichilo nama-coiler. Ikhoyili ingathunyelwa kumenzi noma umenzi ozosebenzisa leyo nto ukudala umkhiqizo oqediwe.

ukupakishwa olwandle okujwayelekile kwekhoyili yensimbi engagqwali

Ukupakisha olwandle okujwayelekile kokuthumela ngaphandle:

Iphepha Elingangeni Manzi + Ifilimu ye-PVC + Ibhande Lebhande + Iphalethi Lokhuni noma Ikesi Lokhuni;

Ukupakishwa okwenziwe ngokwezifiso njengesicelo sakho (Ilogo noma okunye okuqukethwe kuyamukelwa ukuthi kuphrintwe ephaketheni);

Okunye ukupakisha okukhethekile kuzoklanywa njengesicelo sekhasimende;

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.