Ishidi Lensimbi Eliphezulu Elithengiswayo Eliphezulu Le-Dx52d Z140 Lokwakha Ishidi Lophahla Lwensimbi

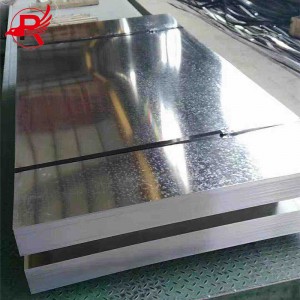

Ishidi elihlanganisiwe liwuhlobo lwezinto zensimbi ezimbozwe nge-zinc ebusweni bepuleti lensimbi, ezisetshenziswa kakhulu ukuvimbela ukugqwala kwensimbi nokwandisa ukuqina kwayo. Ishidi elihlanganisiwe livame ukuba yinqubo yokugaya ngokushisa, okungukuthi, ipuleti lensimbi licwiliswa esixazululweni se-zinc esincibilikisiwe ukuze kwakhiwe ungqimba lwe-zinc olufanayo ebusweni balo. Lokhu kwelashwa kungavimbela ngempumelelo insimbi ukuthi ingaguguleki ngumoya, amanzi namakhemikhali, futhi kwandise isikhathi sayo sokusebenza.

Izinzuzo zeshidi eligoqiwe zihlanganisa ukumelana okuhle nokugqwala, amandla aphezulu nokuqina, ukusebenza kahle kokucubungula kanye nokusebenza kokuhlobisa. Lisetshenziswa kabanzi ekwakheni, ifenisha, ekukhiqizeni izimoto, imishini kagesi nakwezinye izinkambu. Embonini yokwakha, amashidi agoqiwe avame ukusetshenziselwa ukwenza izingxenye ezifana nophahla, izindonga, amapayipi neminyango kanye namafasitela ukuthuthukisa ukumelana kwawo nokugqwala kanye nobuhle. Embonini yezimoto, amashidi agoqiwe asetshenziselwa ukwenza amagobolondo omzimba kanye nezingxenye ukwandisa ukumelana kwawo nesimo sezulu kanye nokuqina kwawo.

Ngokuvamile, ishidi le-galvanized linokumelana okuhle kokugqwala kanye nezakhiwo zemishini, liyinto ebalulekile yensimbi, ngoba ukuvikela insimbi ekugqwaleni nokwandisa impilo yayo yenkonzo kudlala indima ebalulekile.

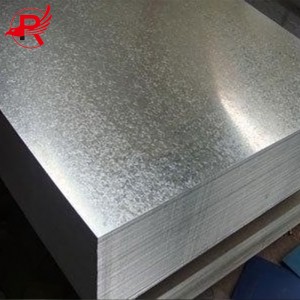

1. Ukumelana nokugqwala, ukupendwa kalula, ukwakheka kahle kanye nokushiselwa kwamabala.

2. Inezindlela eziningi zokusebenzisa, ikakhulukazi ezisetshenziselwa izingxenye zezinto zasekhaya ezincane ezidinga ukubukeka okuhle, kodwa ibiza kakhulu kune-SECC, ngakho abakhiqizi abaningi bashintshela ku-SECC ukuze bonge izindleko.

3. Ihlukaniswe yi-zinc: ubukhulu be-span kanye nobukhulu besendlalelo se-zinc kungabonisa ikhwalithi ye-galvanizing, uma incane futhi ikhulu kakhulu kungcono. Abakhiqizi bangangeza nokwelashwa okulwa nokunyathelisa iminwe. Ngaphezu kwalokho, ingahlukaniswa ngesendlalelo sayo, njenge-Z12, okusho ukuthi inani eliphelele lesendlalelo kuzo zombili izinhlangothi lingu-120g/mm.

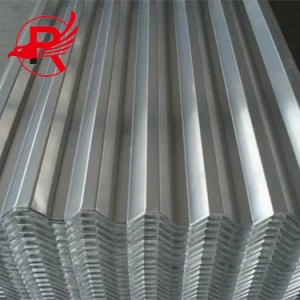

Ishidi Lensimbi Eligayiwekanye nemikhiqizo yensimbi eqoshiwe isetshenziswa kakhulu ekwakhiweni, embonini elula, ezimotweni, kwezolimo, kwezilwane, kwezokudoba kanye nasezimbonini zezentengiselwano. Phakathi kwazo, imboni yokwakha isetshenziswa kakhulu ukukhiqiza amaphaneli ophahla lwezakhiwo zezimboni kanye nezokwakha zomphakathi alwa nokugqwala, amagridi ophahla, njll.; imboni yezimboni zokukhanya iyisebenzisela ukukhiqiza amagobolondo ezinto zasekhaya, oshimula bokwakha, izitsha zasekhishini, njll., kanti imboni yezimoto isetshenziswa kakhulu ukukhiqiza izingxenye zezimoto ezingagqwali, njll.; Ezolimo, kwezilwane kanye nokudoba kusetshenziselwa kakhulu ukugcina nokuthuthwa kokusanhlamvu, inyama eqandisiwe kanye nemikhiqizo yasemanzini, njll.; ezokuhweba zisetshenziselwa kakhulu ukugcina nokuthuthwa kwezinto, imishini yokupakisha, njll.

| Izinga Lobuchwepheshe | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga Lensimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); noma kwamakhasimende Isidingo |

| Ubukhulu | imfuneko yekhasimende |

| Ububanzi | ngokwezidingo zekhasimende |

| Uhlobo Lokumboza | Insimbi Eshisayo Ecwiliswe Ngogesi (HDGI) |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa (C), Ukufaka uwoyela (O), Ukuvala i-Lacquer (L), Ukuphosphating (P), Okungaphathwanga (U) |

| Isakhiwo Somphezulu | Ukugqoka okujwayelekile kwe-spangle (NS), ukugqoka okuncishisiwe kwe-spangle (MS), okungena-spangle (FS) |

| Ikhwalithi | Kuvunywe yi-SGS, ISO |

| ID | 508mm/610mm |

| Isisindo sekhoyili | I-metric ton engu-3-20 nge-coil ngayinye |

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Imakethe yokuthumela ngaphandle | IYurophu, i-Afrika, i-Asia Ephakathi, iNingizimu-mpumalanga ye-Asia, iMpumalanga Ephakathi, iNingizimu Melika, iNyakatho Melika, njll. |

| Ithebula Lokuqhathanisa Ubukhulu Begeji | ||||

| Igeyiji | Okuncane | I-Aluminium | I-Galvanised | Insimbi Engagqwali |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

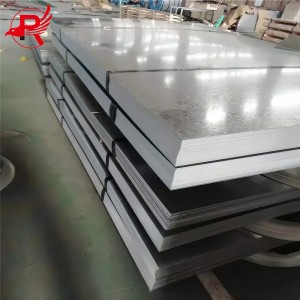

Ukupakishwa okujwayelekile kweIpuleti Lensimbi Elakhiwe Nge-Galvanizedkungahluka kuye ngezinto eziningana okuhlanganisa nomkhiqizi, usayizi weshidi kanye nobuningi. Kodwa-ke, abakhiqizi abaningi bavame ukupakisha amashidi e-GI ngamaqoqo, ngokuvamile izingcezu eziyi-10 kuya kweziyi-100, kanti inqwaba ngayinye igoqwe ngezintambo zepulasitiki noma zensimbi ukuze kuvikelwe kakhulu ngesikhathi sokuthuthwa.

Ngaphezu kwalokho, abanye abakhiqizi banganikeza isivikelo esengeziwe ngokubeka iphakethe ebhokisini lokhuni noma ukugoqa iphakethe ngepulasitiki noma ngekhadibhodi. Ukupakisha kungafaka futhi amalebula noma izimpawu ezibonisa ubukhulu, imininingwane, kanye nolunye ulwazi olufanele mayelana nefomu le-GI.

Kubalulekile ukuqaphela ukuthi ukupakishwa okujwayelekile kungase kungafaneleki kuzo zonke izinhlobo zokuthunyelwa noma zokugcina, ikakhulukazi uma amashidi evezwa ezimweni zezulu ezimbi kakhulu noma ukuphathwa kabi. Ezimweni ezinjalo, izinyathelo ezengeziwe ezifana nokusika, ukuvikela, noma izitsha ezikhethekile zingadingeka ukuze kugcinwe amashidi ephephile.

1. Angakanani amanani akho?

Amanani ethu angashintsha kuye ngokuthi ukunikezwa kwempahla kuyatholakala yini kanye nezinye izici zemakethe. Sizokuthumelela uhlu lwamanani olubuyekeziwe ngemuva kokuxhumana nenkampani yakho.

nathi ukuze uthole ulwazi olwengeziwe.

2. Ingabe unenani elincane kakhulu le-oda?

Yebo, sidinga ukuthi wonke ama-oda aphesheya abe nenani elincane eliqhubekayo le-oda. Uma ufuna ukuthengisa kabusha kodwa ngamanani amancane kakhulu, sincoma ukuthi uhlole iwebhusayithi yethu.

3. Ungakwazi yini ukunikeza amadokhumenti afanele?

Yebo, singanikeza imibhalo eminingi kufaka phakathi Izitifiketi Zokuhlaziya/Ukuhambisana; Umshwalense; Umsuka, kanye neminye imibhalo yokuthumela ngaphandle lapho kudingeka khona.

4. Singakanani isikhathi esimaphakathi sokuhola?

Kumasampula, isikhathi sokuhola cishe siyizinsuku eziyi-7. Ekukhiqizweni ngobuningi, isikhathi sokuhola siyizinsuku ezi-5-20 ngemuva kokuthola inkokhelo yediphozithi. Izikhathi zokuhola ziqala ukusebenza uma

(1) sesiyitholile idiphozithi yakho, futhi (2) sinemvume yakho yokugcina yemikhiqizo yakho. Uma izikhathi zethu zokukhokha zingasebenzi ngesikhathi sakho sokugcina, sicela ubuyekeze izidingo zakho ngokuthengisa kwakho. Kuzo zonke izimo sizozama ukuhlangabezana nezidingo zakho. Ezimweni eziningi siyakwazi ukwenza kanjalo.

5. Yiziphi izinhlobo zezindlela zokukhokha ozamukelayo?

U-30% kusengaphambili nge-T/T, u-70% uzoba ngaphambi kokuthunyelwa okuyisisekelo ku-FOB; u-30% kusengaphambili nge-T/T, u-70% uma kuqhathaniswa nekhophi ye-BL eyisisekelo ku-CIF.