Ishidi Lensimbi Elihlanganisiwe le-ASTM A653M-06a

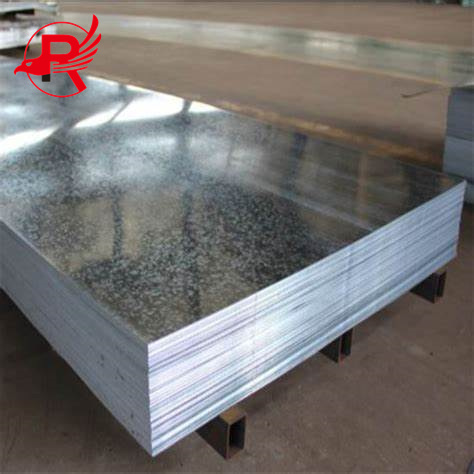

I-Hot-rolledIshidi elihlanganisiwekuwumkhiqizo lapho ungqimba lwe-zinc lumbozwa khona phezu kweshidi lensimbi eligoqwe ngokushisa. Amashidi aqoqwe ngokushisa avame ukusebenzisa inqubo yokugaya ngokushisa, okuwukucwilisa ishidi eligoqwe ngokushisaIpuleti Lensimbi Elakhiwe Nge-Galvanizedkuketshezi lwe-zinc oluncibilikisiwe ukuze kwakheke ungqimba lwe-zinc olufana noluqinile. Lokhu kwelashwa kunikezaIpuleti Lensimbi Elishisayo Eligayiweukumelana okuhle kakhulu nokugqwala, ukumelana nokuguguleka kanye nokumelana nesimo sezulu. Inqubo yokukhiqiza amashidi e-galvanized ashintshwayo ashisa ihlanganisa izinyathelo eziningi ezifana nokulungiswa kwezinto zokusetshenziswa, ukuncibilikisa i-zinc melt, i-hot-dip galvanizing, kanye nokwelashwa kwendawo. Izici zamashidi e-galvanized ashintshwayo ashisa zifaka phakathi ukumelana okuhle kakhulu nokugqwala, ukumelana nokuguguleka, ukusebenza kahle kokucubungula, indawo ebushelelezi nenhle, kanye nokuqhuba kahle kukagesi. Amashidi e-galvanized ashintshwayo ashisa asetshenziswa kabanzi ekwakheni, emishinini, kagesi, kwezokuxhumana nakwamanye amasimu. Avame ukusetshenziswa ezakhiweni zokwakha, ezinhlelweni zokudonsa amanzi, emishinini yezimboni, emishinini yezolimo, ezokuthutha nakwamanye amasimu. Ukumelana kwawo nokugqwala kwenza kube ngenye yezinto ezibalulekile ezimbonini ezahlukene.

Amashidi e-galvanized ashisiwe anezici eziningana ezihlukile ezenza asetshenziswe kabanzi emikhakheni eyahlukahlukene. Okokuqala, amashidi e-galvanized ashisiwe anamandla okugqwala amahle kakhulu. Isendlalelo se-galvanized singavimbela ngempumelelo ubuso bensimbi ukuthi bungcoliswe umoya, amanzi kanye nezinto zamakhemikhali, ngaleyo ndlela sandise impilo yensimbi. Okwesibili, amashidi e-galvanized ashisiwe anamandla okugqwala futhi afaneleka ezindaweni ezidinga ukumelana nokungqubuzana nokuguguleka, njengezakhiwo zokwakha, imishini yemishini kanye neminye imikhakha. Ngaphezu kwalokho, amashidi e-galvanized ashisiwe anamandla okugqwala nawo anezakhiwo ezinhle zokucubungula futhi angacutshungulwa ngokugoba, ukunyathela, ukushisela, njll., futhi afaneleka ukukhiqiza izimo ezahlukahlukene eziyinkimbinkimbi. Ngaphezu kwalokho, ubuso bamashidi e-galvanized ashisiwe abushelelezi futhi amahle, futhi angasetshenziswa ngqo njengezinto zokuhlobisa. Ngaphezu kwalokho, amashidi e-galvanized ashisiwe anamandla okugqwala nawo anokuqhutshwa kahle kukagesi futhi afaneleka amandla kagesi, ukuxhumana kanye neminye imikhakha. Ngokuvamile, ishidi le-galvanized elishisiwe libe ngenye yezinto ezibalulekile emikhakheni yokwakha, imishini, ugesi, ukuxhumana kanye neminye imikhakha ngenxa yokumelana kwayo nokugqwala, ukumelana nokuguguleka kanye nokusebenza kahle kokucubungula.

Ishidi le-galvanized eligoqwe ngokushisa liwumkhiqizo onesendlalelo se-zinc esimbozwe phezu kweshidi lensimbi eligoqwe ngokushisa. Linokumelana okuhle kakhulu nokugqwala kanye nezici ezahlukahlukene. Ngakho-ke, linohlu olubanzi lwezicelo emikhakheni eyahlukene.

Okokuqala, emkhakheni wokwakha, amashidi e-galvanized aguqiwe avame ukusetshenziswa ezinhlelweni zokusekela kanye nokukhipha amanzi ezakhiweni zezakhiwo. Angasetshenziswa ozimele bezakhiwo, izikhonkwane zezitebhisi, izinsimbi zokubiyela nezinye izingxenye, futhi angasetshenziswa njengento eyinhloko yamapayipi okukhipha amanzi ngoba ukumelana kwawo nokugqwala kungandisa impilo yawo yenkonzo ngempumelelo.

Okwesibili, emkhakheni wezimboni, amashidi e-galvanized aguqiwe avame ukusetshenziselwa ukukhiqiza imishini nezingxenye ezahlukahlukene, njengezithangi zokugcina, amapayipi, amafeni, imishini yokudlulisa, njll. Ukumelana nokugqwala kwamashidi e-galvanized kwenza kube lula ukusetshenziswa isikhathi eside ezindaweni ezinzima zezimboni, okuqinisekisa ukusebenza okuphephile kwemishini.

Ngaphezu kwalokho, emkhakheni wezolimo, amashidi e-galvanized ashisiwe nawo anezinzuzo ezibalulekile. Angasetshenziswa ezinhlelweni zokunisela epulazini, ezisekelweni zemishini yezolimo, njll. ngoba ukumelana kwawo nokugqwala kungamelana nokuguguleka kwemishini ngamakhemikhali enhlabathini.

Ngaphezu kwalokho, emkhakheni wezokuthutha, amashidi e-galvanized ashisiwe avame ukusetshenziswa ukukhiqiza izingxenye zezimoto, izingxenye zemikhumbi, njll., ngoba ukumelana kwazo nokugqwala kungandisa impilo yesevisi yezimoto zokuthutha.

Ngokuvamile, amashidi e-galvanized ashisiwe anezicelo ezibalulekile ekwakheni, embonini, kwezolimo, kwezokuthutha nakweminye imikhakha, futhi ukumelana kwawo nokugqwala kuwenza abe ngenye yezinto ezifanelekile zemishini nezakhiwo ezahlukahlukene.

| Izinga Lobuchwepheshe | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga Lensimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); noma kwamakhasimende Isidingo |

| Ubukhulu | imfuneko yekhasimende |

| Ububanzi | ngokwezidingo zekhasimende |

| Uhlobo Lokumboza | Insimbi Eshisayo Ecwiliswe Ngogesi (HDGI) |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa (C), Ukufaka uwoyela (O), Ukuvala i-Lacquer (L), Ukuphosphating (P), Okungaphathwanga (U) |

| Isakhiwo Somphezulu | Ukugqoka okujwayelekile kwe-spangle (NS), ukugqoka okuncishisiwe kwe-spangle (MS), okungena-spangle (FS) |

| Ikhwalithi | Kuvunywe yi-SGS, ISO |

| ID | 508mm/610mm |

| Isisindo sekhoyili | I-metric ton engu-3-20 nge-coil ngayinye |

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Imakethe yokuthumela ngaphandle | IYurophu, i-Afrika, i-Asia Ephakathi, iNingizimu-mpumalanga ye-Asia, iMpumalanga Ephakathi, iNingizimu Melika, iNyakatho Melika, njll. |

| Ithebula Lokuqhathanisa Ubukhulu Begeji | ||||

| Igeyiji | Okuncane | I-Aluminium | I-Galvanised | Insimbi Engagqwali |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.