Ipayipi Elishisayo Elihlanganisiwe

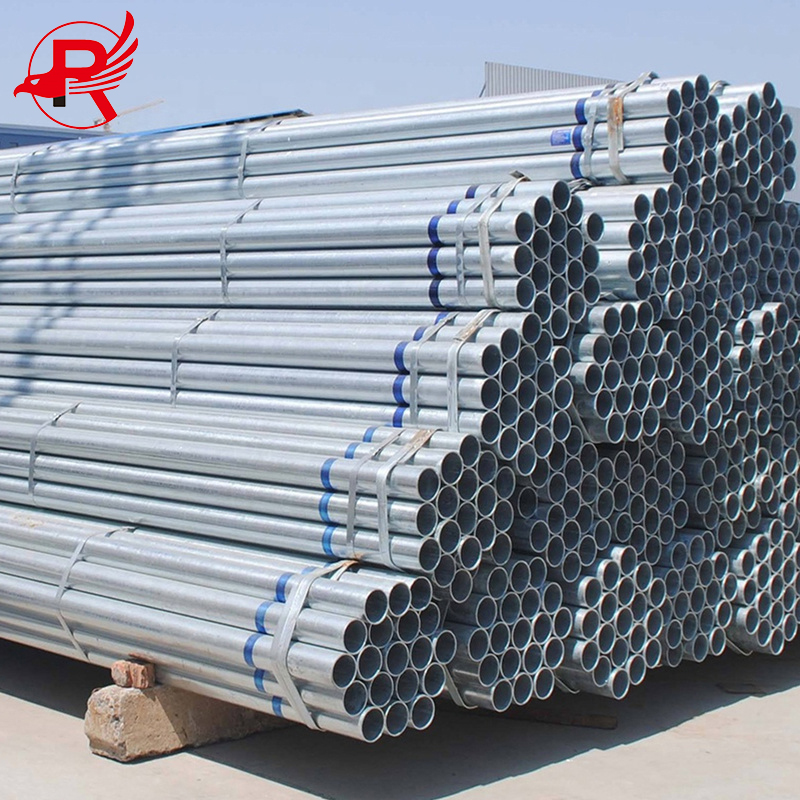

Ipayipi elihlanganisiwe elishisayo liphendula insimbi encibilikisiwe ne-substrate yensimbi ukuze likhiqize ungqimba lwe-alloy, ukuze i-substrate kanye ne-coating kuhlanganiswe. I-hot-dip galvanizing iwukuqhobosha ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuqhobosha, ihlanzwa nge-ammonium chloride noma i-zinc chloride aqueous solution noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese ithunyelwa ethangini lokuqhobosha elishisayo. I-hot-dip galvanizing inezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. I-hot-dip galvanizing steel pipe substrate idlula ekusebenzelaneni okuyinkimbinkimbi ngokomzimba nangokwekhemikhali ngesisombululo sokuqhobosha esincibilikisiwe ukuze kwakhiwe ungqimba lwe-zinc-iron alloy olumelana nokugqwala olunesakhiwo esiqinile. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-substrate yepayipi lensimbi, ngakho-ke lunokumelana okuqinile kokugqwala.

Amapayipi ensimbi afakwe insimbi eshisayo asetshenziswa kabanzi ekwakheni, emishinini, ezimayini zamalahle, kumakhemikhali, kumandla kagesi, ezimotweni zesitimela, embonini yezimoto, emigwaqweni emikhulu, emabhulohweni, ezitsheni, ezindaweni zemidlalo, emishinini yezolimo, emishinini kaphethiloli, emishinini yokuhlola, ekwakhiweni kwezindawo zokugcina izithombo kanye nakwezinye izimboni zokukhiqiza.

Isisindo Esibalulekile

Ubukhulu bodonga obujwayelekile (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Amapharamitha e-coefficient (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Qaphela: Izakhiwo zensimbi ezisebenza ngomshini ziyisibonakaliso esibalulekile sokuqinisekisa ukusebenza kokugcina kokusetshenziswa (izakhiwo zensimbi) zensimbi, okuncike ekwakhiweni kwamakhemikhali kanye nohlelo lokwelashwa kokushisa kwensimbi. Ezindinganisweni zamapayipi ensimbi, izakhiwo zokudonsa (amandla okudonsa, amandla okudonsa noma iphuzu lokudonsa, ukunwebeka), ubulukhuni, ukuqina, kanye nezakhiwo zokushisa eziphakeme neziphansi ezidingwa abasebenzisi zichazwa ngokuya ngezidingo ezahlukene zokusebenzisa.

Amazinga ensimbi: Q215A; Q215B; Q235A; Q235B.

Inani lokucindezela kokuhlola/i-Mpa: D10.2-168.3mm ingu-3Mpa; D177.8-323.9mm ingu-5Mpa

Izinga Likazwelonke Lamanje

Izinga likazwelonke kanye nezinga losayizi wepayipi elihlanganisiwe

Amapayipi ensimbi ahlanganisiwe e-GB/T3091-2015 okuthuthwa koketshezi olunomfutho ophansi

Ipayipi lensimbi elihlanganisiwe likagesi elihlanganisiwe le-GB/T13793-2016 lomthungo oqondile

Ubukhulu bepayipi lensimbi elihlanganisiwe le-GB/T21835-2008 kanye nesisindo ngobude beyunithi ngayinye

Isikhathi sokuthunyelwe: Juni-06-2023