-

Ipayipi Lensimbi Eyindilinga Eshisayo ye-SAE 1008 1010 1020

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

Njengoba sineminyaka engaphezu kwengu-10 sinolwazi lokuthumela insimbi emazweni angaphezu kwe-100, sithole idumela elihle futhi sinamaklayenti amaningi avamile.

Sizokusekela kahle kuyo yonke inqubo ngolwazi lwethu lobuchwepheshe kanye nezimpahla ezisezingeni eliphezulu.

Isampula Yesitoko Imahhala Futhi Iyatholakala! Siyakwamukela umbuzo wakho!

-

Ipayipi Lensimbi Eshisayo Ehlanganisiwe Ye-GI Eyindilinga Esezingeni Eliphezulu Engu-15mm

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

-

Ipayipi le-GI Ipayipi Lensimbi Elakhiwe Ngaphambili Eligayiwe Ipayipi Eligayiwe Lokwakha

UkushiselaIpayipi Elihlanganisiwengokuvamile yenziwa ngensimbi ephansi yekhabhoni futhi isetshenziswa kabanzi ezinhlotsheni ezahlukahlukene njengokwakha, ingqalasizinda, izimboni, kanye namaphrojekthi okuhlala. Inqubo yokufakwa kwe-galvanization inikeza ipayipi lensimbi ukuqina okwengeziwe kanye nokuphila isikhathi eside, okwenza lifanelekele izimo zangaphandle nezivezwe.

Inzuzo eyinhloko yeipayipi lensimbi elifakwe i-galvanized kusengaphambiliukumelana kwayo nokugqwala. Isembozo se-zinc sisebenza njengesivikelo esivimbela umswakama nezinye izinto ezigqwala ukuthi zingathintani nensimbi engaphansi. Lokhu kwenza ipayipi lensimbi elisetshenziswe ngaphambilini lingabi sengozini yokugqwala nokugqwala, okwandisa isikhathi sayo sokuphila futhi kunciphisa izindleko zokulungisa.

Ngaphezu kwalokho,Ipayipi Elishisayo Elihlanganisiweyaziwa ngamandla ayo aphezulu nokuqina kwayo. Ingamelana nemithwalo esindayo futhi inikeza ubuqotho obuhle kakhulu besakhiwo, okwenza kube ukukhetha okuthembekile kwezicelo ezidinga ipayipi eliqinile neliqinile.

-

Amapayipi Nezinki Zensimbi Yekhabhoni Embozwe Ngezinki Ishubhu Lokusika Ipayipi Lensimbi Eshisayo Ecwiliswe Ngegesi

InsimbiisikafulaI-bracket iyisakhiwo sesikhashana esinikeza ipulatifomu ezinzile yabasebenzi yokwenza umsebenzi wokwakha, wokulungisa noma wokulungisa ezindaweni eziphakeme. Yakhiwa ngamapayipi ensimbi kanye nezinto zokufakelwa ezihlanganiswe ndawonye ukuze zakhe uhlaka oluzinzile. Izisekelo ze-scaffolding zensimbi zingahluka ngobukhulu kanye nokucushwa, kuye ngohlobo lomsebenzi okudingeka wenziwe kanye nokuphakama okudingekayo.

-

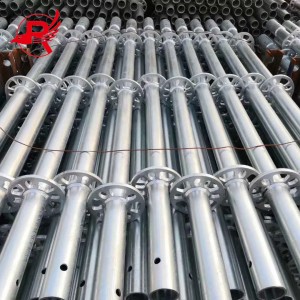

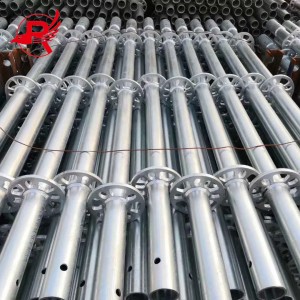

I-Scaffold Ephelele Yensimbi Enzima I-Hot Dip Ehlanganisiwe Yonke I-Layher Ringlock System Scaffolding Iyathengiswa

InsimbiisikafulaI-bracket iyisakhiwo sesikhashana esinikeza ipulatifomu ezinzile yabasebenzi yokwenza umsebenzi wokwakha, wokulungisa noma wokulungisa ezindaweni eziphakeme. Yakhiwa ngamapayipi ensimbi kanye nezinto zokufakelwa ezihlanganiswe ndawonye ukuze zakhe uhlaka oluzinzile. Izisekelo ze-scaffolding zensimbi zingahluka ngobukhulu kanye nokucushwa, kuye ngohlobo lomsebenzi okudingeka wenziwe kanye nokuphakama okudingekayo.

-

I-Scaffold Yensimbi Esetshenzisiwe Yokwakha Esezingeni Eliphezulu Iyathengiswa

InsimbiisikafulaI-bracket iyisakhiwo sesikhashana esinikeza ipulatifomu ezinzile yabasebenzi yokwenza umsebenzi wokwakha, wokulungisa noma wokulungisa ezindaweni eziphakeme. Yakhiwa ngamapayipi ensimbi kanye nezinto zokufakelwa ezihlanganiswe ndawonye ukuze zakhe uhlaka oluzinzile. Izisekelo ze-scaffolding zensimbi zingahluka ngobukhulu kanye nokucushwa, kuye ngohlobo lomsebenzi okudingeka wenziwe kanye nokuphakama okudingekayo.

-

Ipayipi Lensimbi Ehlanganisiwe Eshisayo Ecwiliswe Ngesikhafu

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

Njengoba sineminyaka engaphezu kwengu-10 sinolwazi lokuthumela insimbi emazweni angaphezu kwe-100, sithole idumela elihle futhi sinamaklayenti amaningi avamile.

Sizokusekela kahle kuyo yonke inqubo ngolwazi lwethu lobuchwepheshe kanye nezimpahla ezisezingeni eliphezulu.

Isampula Yesitoko Imahhala Futhi Iyatholakala! Siyakwamukela umbuzo wakho!

-

I-HDG Tube China Factory Intengo Eqondile Yamapayipi Ensimbi Ahlanganisiwe Ajikelezisiwe

Ipayipi lensimbi eliyindilinga elihlanganisiweuhlobo lwepayipi lensimbi eliyindilinga elinobuso obuphathwa nge-hot-dip galvanizing noma i-cold-dip galvanizing, okunikeza ukumelana nokugqwala okuhle kakhulu nokuqina. Lisetshenziswa kabanzi ekwakheni, ekukhiqizeni imishini, ezindaweni zezolimo, ekuthuthweni kwamapayipi, ezinsikeni zokuvikela, kanye nasezindlini zezimboni.

-

I-EN10255 8 intshi S235 Insimbi Eshisayo Egoqwe Kancane Ekhabhoni Embozwe I-Zinc Embozwe Ipayipi Lensimbi Egayiwe Namapayipi

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

-

Ipayipi Eliyindilinga Lensimbi Ehlanganisiwe Yekhabhoni Ehlanganisiwe ye-Astm Ms GI

I-hot-dip galvanization iwuhlobo lwe-galvanization. Inqubo yokumboza insimbi nensimbi nge-zinc, ehlanganisa ubuso bensimbi eyisisekelo lapho ifaka insimbi ebhavini le-zinc encibilikisiwe ekushiseni okungaba ngu-450 °C (842 °F).

-

Ipayipi Eliyindilinga Lensimbi Ehlanganisiwe Eyi-1/2 intshi Embozwe Nge-Zinc

Gipayipi elihlanganisiweYenziwe nge-metal encibilikisiwe kanye ne-iron matrix reaction ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix kanye ne-coating kube yinhlanganisela emibili.gUkuhlanza ipayipi lensimbi kuqala. Ukuze kususwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuhlanza, kuhlanzwa ethangini ngesisombululo se-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo samanzi esixubile se-ammonium chloride ne-zinc chloride, bese kuthunyelwa ethangini lokufaka i-hot dip plating. Ukuhlanza i-hot dip galvanizing kunezinzuzo zokugqoka okufanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside kwenkonzo. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo sepayipi lensimbi kanye nebhavu elincibilikisiwe ukuze kwakheke ungqimba oluhlanganisiwe lwe-zinc-iron alloy olunokumelana nokugqwala. Ungqimba lwe-alloy luhlanganiswe nongqimba lwe-zinc oluhlanzekile kanye ne-matrix yepayipi lensimbi. Ngakho-ke, ukumelana kwalo nokugqwala kunamandla.

-

Ipayipi Lensimbi Eyindilinga Ehlanganisiwe Eyi-Hot-DIP engu-60.3*2.5mm Yokwakha

I-hot-dip galvanizing iyindlela yokuhlanganisa i-zinc futhi iyindlela evame kakhulu yokufaka i-zinc coating. Kule nqubo, insimbi ifakwa ebhavini le-zinc elincibilikisiwe cishe ku-450 °C (842 °F). I-zinc isabela ebusweni bensimbi futhi yakha ungqimba lwe-alloy olumelana nokugqwala oluvikela insimbi.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur