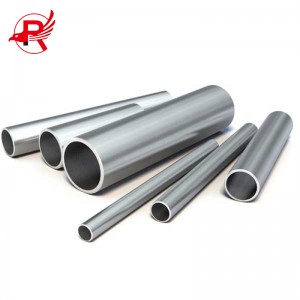

Ipayipi Lensimbi Engagqwali Elingenamthungo Leqembu Lasebukhosini 201 202 204

| Igama Lomkhiqizo | Ipayipi eliyindilinga lensimbi engagqwali |

| Okujwayelekile | I-ASTM AISI DIN, EN, GB, JIS |

| Ibanga Lensimbi

| Uchungechunge lwama-200: 201,202 |

| Uchungechunge lwama-300: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| Uchungechunge lwe-400: 409L,410,410s,420j1,420j2,430,444,441,436 | |

| Insimbi Ephindwe Kabili: 904L, 2205, 2507, 2101, 2520, 2304 | |

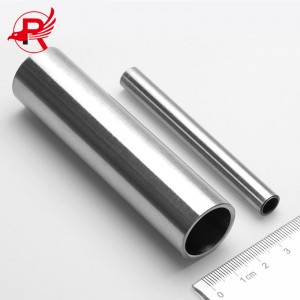

| Ububanzi Bangaphandle | 6-2500mm (njengoba kudingeka) |

| Ubukhulu | 0.3mm-150mm (njengoba kudingeka) |

| Ubude | 2000mm/2500mm/3000mm/6000mm/12000mm (njengoba kudingeka) |

| Ubuchwepheshe | Akunamthungo |

| Ubuso | Inombolo 1 2B BA 6K 8K Isibuko No.4 HL |

| Ukubekezelelana | ±1% |

| Imigomo Yentengo | I-FOB, i-CFR, i-CIF |

Ipayipi lensimbi engagqwali uhlobo lwensimbi eyindilinga ende engenalutho, esetshenziswa kakhulu kumapayipi ezokuthutha ezimbonini afana ne-petroleum, imboni yamakhemikhali, ukwelashwa kwezokwelapha, ukudla, imboni elula, ithuluzi lomshini, njll., kanye nezingxenye zesakhiwo somshini. Ngaphezu kwalokho, lapho ukugoba namandla okugoba kufana, isisindo silula, ngakho-ke sisetshenziswa kabanzi ekwenziweni kwezingxenye zomshini kanye nezakhiwo zobunjiniyela. Isetshenziswa futhi njengefenisha nezinto zasekhishini, njll.

Inothi:

1. Isampula yamahhala, isiqinisekiso sekhwalithi ngemuva kokuthengisa esingu-100%, Sekela noma iyiphi indlela yokukhokha;

2. Zonke ezinye izincazelo zamapayipi ensimbi eyindilinga yekhabhoni ziyatholakala ngokwezidingo zakho (OEM & ODM)! Intengo yasefektri uzoyithola kwa-ROYAL GROUP.

Izakhi Zamakhemikhali Zepayipi Lensimbi Engagqwali

| Ukwakheka Kwamakhemikhali % | ||||||||

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Ngokusebenzisa izindlela ezahlukene zokucubungula ukugoqa okubandayo kanye nokucubungula kabusha ubuso ngemva kokugoqa, ukuqeda ubuso kwensimbi engagqwaliibhaAma-s angaba nezinhlobo ezahlukene.

Ukucubungula ubuso bepayipi lensimbi engagqwali kune-NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright kanye nokunye ukuqedwa kwendawo, njll.

NO.1: Ubuso obunguNombolo 1 bubhekisela ebusweni obutholakala ngokwelashwa ngokushisa kanye nokuphotha ngemva kokuphotha ngokushisa kwepayipi lensimbi engagqwali. Kuwukususa isikali se-oxide emnyama esikhiqizwa ngesikhathi sokuphotha ngokushisa kanye nokwelashwa ngokushisa ngokuphotha noma izindlela ezifanayo zokwelapha. Lokhu kungukucubungula ubuso obunguNombolo 1. Ubuso obunguNombolo 1 bumhlophe njengesiliva futhi abunawo umbala. Kusetshenziswa kakhulu ezimbonini ezingamelani nokushisa kanye nezingamelani nokugqwala ezingadingi ukukhanya kobuso, njengemboni yotshwala, imboni yamakhemikhali kanye nezitsha ezinkulu.

2B: Ubuso be-2B buhlukile kobuso be-2D ngoba bubushelelezi nge-roller ebushelelezi, ngakho-ke bukhanya kakhulu kunobuso be-2D. Ubulukhuni bobuso Inani le-Ra elilinganiswa yithuluzi lingu-0.1 ~0.5μm, okuwuhlobo lokucubungula oluvame kakhulu. Lolu hlobo lobuso bensimbi engagqwali luyizinto eziningi kakhulu, lufanelekela izinjongo ezijwayelekile, olusetshenziswa kabanzi embonini yamakhemikhali, ephepheni, ephethroli, kwezokwelapha nakwezinye izimboni, futhi lungasetshenziswa njengodonga lwekhethini lesakhiwo.

Ukuqeda Okuqinile kwe-TR: Insimbi engagqwali ye-TR ibizwa nangokuthi insimbi eqinile. Amazinga ayo ensimbi amele angama-304 nama-301, asetshenziselwa imikhiqizo edinga amandla aphezulu nokuqina, njengezimoto zesitimela, amabhande okuhambisa, izipilingi nama-gasket. Umgomo ukusebenzisa izici zokuqinisa umsebenzi zensimbi engagqwali ye-austenitic ukwandisa amandla nokuqina kwepuleti lensimbi ngezindlela zokusebenza ezibandayo njengokugoqa. Izinto eziqinile zisebenzisa amaphesenti ambalwa kuya kwamashumi ambalwa amaphesenti okugoqa okuthambile ukuze kuthathelwe indawo ukuthamba okuthambile kobuso besisekelo se-2B, futhi akukho ukugoqa okwenziwayo ngemva kokugoqa. Ngakho-ke, ubuso be-TR obunzima bezinto eziqinile buwubuso obugoqa ngemva kokugoqa okubandayo.

Okugoqekile Okukhanyayo 2H: Ngemva kwenqubo yokugoqa, ipayipi lensimbi engagqwali lizocutshungulwa ukugoqa okukhanyayo. Ipayipi lingapholiswa ngokushesha ngomugqa wokugoqa oqhubekayo. Ijubane lokuhamba lepayipi lensimbi engagqwali emgqeni licishe libe ngu-60m ~ 80m/min. Ngemva kwalesi sinyathelo, ukuphela kobuso kuzoba ngu-2H okugoqekile okukhanyayo.

Inombolo 4: Ubuso beNombolo 4 buyisiphetho esihle esicwebezelayo esikhanya kakhulu kunobuso beNombolo 3. Butholakala nangokupholisha ipayipi lensimbi engagqwali eligoqwe ngokubandayo elinobuso obungu-2 D noma obungu-2 B njengesisekelo bese upholisha ngebhande elinobukhulu obungu-150-180# Ubuso obufakwe ngomshini. Ubulukhuni bobuso Inani le-Ra elilinganiswa yithuluzi lingu-0.2 ~ 1.5μm. Ubuso beNombolo 4 busetshenziswa kabanzi emishinini yokudlela nasekhishini, imishini yezokwelapha, imihlobiso yezakhiwo, izitsha, njll.

I-HL: Ubuso be-HL buvame ukubizwa ngokuthi ukuphela kwezinwele. Izinga le-JIS laseJapan libeka ukuthi ibhande elinobukhulu obungu-150-240# lisetshenziselwa ukupholisha ubuso obunobukhulu obufana nobezinwele obutholakalayo. Ezingeni le-GB3280 laseShayina, imithetho ayicacile. Ukuphela kwezinwele ze-HL kusetshenziselwa kakhulu ukuhlobisa izakhiwo njengezinyusi, izitebhisi, kanye nama-facade.

No.6: Ubuso beNombolo 6 busekelwe ebusweni beNombolo 4 futhi bupholishwa ngebhulashi leTampico noma izinto ezihudulayo ezinosayizi wezinhlayiya ze-W63 ezichazwe yi-GB2477 standard. Lobu buso bunokukhanya okuhle kwensimbi nokusebenza okuthambile. Ukukhanya kubuthakathaka futhi akubonisi isithombe. Ngenxa yalesi sici esihle, kufanelekile kakhulu ukwenza izindonga zamakhethini esakhiwo kanye nemihlobiso yemiphetho yesakhiwo, futhi isetshenziswa kabanzi njengezitsha zasekhishini.

I-BA: I-BA iwubuso obutholakala ngokwelashwa kokushisa okukhanyayo ngemva kokugoqa okubandayo. Ukwelashwa kokushisa okukhanyayo kuwukunamathela ngaphansi komkhathi ovikelayo oqinisekisa ukuthi ubuso abukhiqizwanga ukuze kulondolozwe ukukhanya kobuso obugoqa okubandayo, bese usebenzisa i-roll yokushelela enembile kakhulu ukuze kulinganiswe ukukhanya ukuze kuthuthukiswe ukukhanya kobuso. Lobu buso buseduze nokuqedwa kwesibuko, futhi ubulukhuni bobuso Inani le-Ra elilinganiswa yithuluzi lingu-0.05-0.1μm. Ubuso be-BA bunokusetshenziswa okubanzi futhi bungasetshenziswa njengezitsha zasekhishini, izinto zasekhaya, imishini yezokwelapha, izingxenye zezimoto kanye nemihlobiso.

Inombolo 8: Inombolo 8 iyindawo eqediwe ngesibuko enokukhanya okuphezulu kakhulu ngaphandle kwezinhlayiya ezirhabaxa. Imboni yokucubungula okujulile kwensimbi engagqwali nayo ibiza amapuleti angu-8K. Ngokuvamile, izinto ze-BA zisetshenziswa njengezinto zokusetshenziswa zokuqeda isibuko ngokugaya nokupholisha kuphela. Ngemva kokuqeda isibuko, indawo iwubuciko, ngakho-ke isetshenziswa kakhulu ekuhlobiseni indawo yokungena esakhiweni kanye nasekuhlobiseni ingaphakathi.

Inqubo eyinhloko yokukhiqiza: insimbi eyindilinga → ukuhlolwa kabusha → ukuhlubuka → ukumboza → ukugxilisa phakathi → ukushisa → ukubhoboza → ukukhahlela → ikhanda eliyisicaba → ukuhlolwa nokugaya → ukugoqa okubandayo (ukudweba okubandayo) → ukususa amafutha → ukwelashwa kokushisa → ukuqondisa → ukusika ipayipi (okuqondile ubude) ) → ukukhahlela/ukudlulisa amanzi → ukuhlolwa komkhiqizo okuqediwe (umshini wamanzi we-eddy, i-ultrasonic, ingcindezi yamanzi) → ukupakishwa nokugcinwa.

1. Ukusikwa kwensimbi eyindilinga: Ngemva kokuthola insimbi eyindilinga esitolo sokugcina izinto zokusetshenziswa, bala ubude bokusika kwensimbi eyindilinga ngokwezidingo zenqubo, bese udweba umugqa ensimbini eyindilinga. Izinsimbi zibekwe ngokwezinga lensimbi, izinombolo zokushisa, izinombolo zebhetshi yokukhiqiza kanye nemininingwane, kanti iziphetho zihlukaniswa ngopende wemibala ehlukene.

2. Ukubeka phakathi: Uma ubeka phakathi umshini wokubhoboza ingalo evundlile, qala uthole indawo ephakathi engxenyeni yensimbi eyindilinga, ubhoboze imbobo yesampula, bese uyilungisa iqonde etafuleni lomshini wokubhoboza ukuze ifakwe phakathi. Amabha ayindilinga ngemva kokubeka phakathi abekwa ngokwezinga lensimbi, inombolo yokushisa, imininingwane kanye nenombolo yebhetshi yokukhiqiza.

3. Ukuhlubula: ukuhlubula kwenziwa ngemva kokuhlolwa kwezinto ezingenayo. Ukuhlubula kufaka phakathi ukuhlubula nge-lathe kanye nokusika nge-whirlpool. Ukuhlubula nge-lathe kwenziwa ku-lathe ngendlela yokucubungula nge-clamp eyodwa kanye ne-top eyodwa, kanti ukuhlubula nge-whirlpool kuwukulengisa insimbi eyindilinga ethuluzini lomshini. Yenza ukuzungeza.

4. Ukuhlolwa kobuso: Kuhlolwa ikhwalithi yensimbi eyindilinga ehlutshiwe, bese kubhalwa amaphutha obuso akhona, bese abasebenzi bokugaya bazowagaya kuze kube yilapho efanelekile. Imigoqo eyindilinga edlulile ekuhlolweni inqwabelana ngokwehlukana ngokwezinga lensimbi, inombolo yokushisa, imininingwane kanye nenombolo yebhetshi yokukhiqiza.

5. Ukushisa ngensimbi eyindilinga: Imishini yokushisa ngensimbi eyindilinga ihlanganisa isithando somlilo esifakwe igesi kanye nesithando somlilo esifakwe igesi. Isithando somlilo esifakwe igesi esifakwe igesi sisetshenziselwa ukufudumeza ngamaqoqo amakhulu, kanti isithando somlilo esifakwe igesi sisetshenziselwa ukufudumeza ngamaqoqo amancane. Lapho ungena esithandweni, amabha ayindilinga ezinhlobo ezahlukene zensimbi, izinombolo zokushisa kanye nemininingwane kuhlukaniswa yifilimu yangaphandle endala. Lapho amabha ayindilinga efudunyezwa, ama-turner asebenzisa amathuluzi akhethekile ukujikisa amabha ukuqinisekisa ukuthi amabha ayindilinga afudunyezwa ngokulinganayo.

6. Ukubhoboza okushisayo: sebenzisa iyunithi yokubhoboza kanye ne-air compressor. Ngokwezincazelo zensimbi eyindilinga ebhobozekile, kukhethwa amapuleti okuqondisa ahambisanayo kanye nama-plug e-molybdenum, bese kukhethwa insimbi eyindilinga efudumele nge-perforator, bese kuthi amapayipi kadoti abhobozekile afakwe ngokungahleliwe echibini ukuze aphole ngokuphelele.

7. Ukuhlolwa nokugaya: Hlola ukuthi ubuso bangaphakathi nangaphandle bepayipi likadoti bubushelelezi futhi bubushelelezi, futhi akumele kube nesikhumba sembali, imifantu, izingqimba ezihlanganisiwe, imigodi ejulile, izimpawu ezinkulu zentambo, insimbi yombhoshongo, ama-fritters, ama-Baotou nama-sickle heads. Amaphutha ebusweni bepayipi likadoti angasuswa ngendlela yokugaya yendawo. Amapayipi kadoti aphumelele ukuhlolwa noma lawo aphumelele ukuhlolwa ngemva kokulungisa nokugaya amaphutha amancane kufanele ahlanganiswe yi-workshop bundlers ngokwezidingo, futhi abekwe ngokwezinga lensimbi, inombolo yesithando somlilo, imininingwane kanye nenombolo yebhetshi yokukhiqiza yepayipi likadoti.

8. Ukuqondisa: Amapayipi emfucuza angenayo endaweni yokusebenzela ebhobozayo apakishwe ngamaqoqo. Isimo sepayipi lemfucuza engenayo sigobile futhi sidinga ukuqondisa. Imishini yokuqondisa umshini wokuqondisa oqondile, umshini wokuqondisa ovundlile kanye nomshini wokucindezela we-hydraulic oqondile (osetshenziselwa ukuqondisa kwangaphambili lapho ipayipi lensimbi linomugqa omkhulu). Ukuze kuvinjelwe ipayipi lensimbi ukuthi lingagxumi ngesikhathi sokuqondisa, kusetshenziswa isikhonkwane se-nylon ukunciphisa ipayipi lensimbi.

9. Ukusika amapayipi: Ngokohlelo lokukhiqiza, ipayipi likadoti eliqondile lidinga ukunqunywa ikhanda nomsila, kanti imishini esetshenziswayo umshini wokusika amasondo okugaya.

10. Ukuqoqwa: Ipayipi lensimbi eliqondile lidinga ukuqoqwa ukuze kususwe isikali se-oxide kanye nokungcola ebusweni bepayipi likadoti. Ipayipi lensimbi liqoqwa endaweni yokusebenzela yokuqoqwa, bese ipayipi lensimbi liphakanyiswa kancane kancane ethangini lokuqoqwa ukuze liqoqwe ngokushayela.

11. Ukugaya, ukuhlolwa kwe-endoscopy kanye nokupholisha kwangaphakathi: amapayipi ensimbi afanelekela ukupholisha angena enkambisweni yokugaya yangaphandle, amapayipi ensimbi apholisha ahlolwa nge-endoscopic, kanti imikhiqizo noma izinqubo ezingafaneleki ezinezidingo ezikhethekile kudingeka zipholishwe ngaphakathi.

12. Inqubo yokugoqa ebandayo/inqubo yokudweba ebandayo

Ukugoqa okubandayo: Ipayipi lensimbi ligoqwa yimiqulu yesigayo sokugoqa okubandayo, futhi ubukhulu nobude bepayipi lensimbi kushintsha ngenxa yokuguquka okubandayo okuqhubekayo.

Ukudweba Okubandayo: Ipayipi lensimbi liyavutha futhi lincishiswa odongeni ngomshini wokudweba obandayo ngaphandle kokushisa ukuze kushintshwe usayizi nobude bepayipi lensimbi. Ipayipi lensimbi elidonswayo elibandayo linokunemba okuphezulu kanye nokuphela okuhle kobuso. Okubi ukuthi ukucindezeleka okusele kukhulu, futhi amapayipi amakhulu adonswayo abandayo avame ukusetshenziswa, futhi isivinini sokwakha umkhiqizo oqediwe sihamba kancane. Inqubo ethile yokudweba okubandayo ifaka:

① Ikhanda lokushisela eliyisihloko: Ngaphambi kokudweba okubandayo, ingxenye eyodwa yepayipi lensimbi idinga ukushiselwa (ipayipi lensimbi elincane eliyisiqu) noma ikhanda lokushisela (ipayipi lensimbi elikhulu eliyisiqu) ukuze kulungiselelwe inqubo yokudweba, futhi inani elincane lepayipi lensimbi elicacisiwe elikhethekile lidinga ukushiswa bese lishiselwa.

② Ukugcoba nokubhaka: Ngaphambi kokudonsa okubandayo kwepayipi lensimbi ngemuva kwekhanda (ikhanda lokushisela), imbobo yangaphakathi kanye nobuso bangaphandle bepayipi lensimbi kufanele kugcotshwe, bese ipayipi lensimbi elimbozwe ngokugcoba kufanele lomiswe ngaphambi kokudonsa okubandayo.

③ Ukudweba okubandayo: Ipayipi lensimbi ngemva kokuba igrisi lomisiwe lingena enkambisweni yokudweba okubandayo, futhi imishini esetshenziselwa ukudweba okubandayo umshini wokudweba obandayo weketanga kanye nomshini wokudweba obandayo we-hydraulic.

13. Ukususa amafutha: Inhloso yokususa amafutha ukususa uwoyela ogoqekayo onamathele odongeni lwangaphakathi nangaphandle kwepayipi lensimbi ngemva kokugoqa ngokuhlambulula, ukuze kugwenywe ukungcolisa ubuso bensimbi ngesikhathi sokunamathela nokuvimbela ukwanda kwekhabhoni.

14. Ukwelashwa ngokushisa: Ukwelashwa ngokushisa kubuyisela isimo sezinto ngokuphinda kusetshenziswe futhi kunciphisa ukumelana nokuguquguquka kwensimbi. Imishini yokwelapha ngokushisa iyisithando sokwelapha ngokushisa sesixazululo segesi yemvelo.

15. Ukuqoqwa kwemikhiqizo eqediwe: Amapayipi ensimbi ngemva kokusikwa afakwa ekuqoqweni okuqediwe ngenhloso yokudlulisa ubuso, ukuze kwakhiwe ifilimu evikela i-oxide ebusweni bamapayipi ensimbi futhi kuthuthukiswe ukusebenza okuhle kakhulu kwamapayipi ensimbi.

16. Ukuhlolwa komkhiqizo oqediwe: Inqubo eyinhloko yokuhlola nokuhlola umkhiqizo oqediwe ukuhlolwa kwemitha → i-eddy probe → i-super probe → ingcindezi yamanzi → ingcindezi yomoya. Ukuhlolwa kobuso ngokuyinhloko kuhloswe ukuhlola ngesandla ukuthi kukhona amaphutha ebusweni bepayipi lensimbi, ukuthi ubude bepayipi lensimbi nosayizi wodonga lwangaphandle kuyafaneleka yini; ukutholwa kwe-eddy kusebenzisa kakhulu i-eddy current flaw detector ukuhlola ukuthi kukhona yini amaphutha epayipini lensimbi; ukutholwa okuphezulu kusebenzisa kakhulu i-ultrasonic flaw detector ukuhlola ukuthi ipayipi lensimbi liqhekekile ngaphakathi noma ngaphandle; ukucindezeleka kwamanzi, ingcindezi yomoya ukusebenzisa umshini we-hydraulic kanye nomshini wokucindezela umoya ukuthola ukuthi ipayipi lensimbi livuza amanzi noma umoya, ukuqinisekisa ukuthi ipayipi lensimbi lisesimweni esihle.

17. Ukupakisha kanye nokugcina impahla: Amapayipi ensimbi aphumelele ukuhlolwa angena endaweni yokupakisha umkhiqizo oqediwe ukuze apakishwe. Izinto ezisetshenziselwa ukupakisha zifaka phakathi izimbobo zemigodi, izikhwama zepulasitiki, indwangu yesikhumba senyoka, amabhodi ezinkuni, amabhande ensimbi angagqwali, njll. Ubuso bangaphandle bomabili amaphethelo epayipi lensimbi eligoqiwe limbozwe ngamabhodi amancane ezinkuni, kanti ubuso bangaphandle buboshwe ngamabhande ensimbi angagqwali ukuvimbela ukuthintana phakathi kwamapayipi ensimbi ngesikhathi sokuthuthwa futhi kubangele ukushayisana. Amapayipi ensimbi apakishiwe angena endaweni yokubeka umkhiqizo oqediwe.

Ukupakisha ngokuvamile akunalutho, kubopha ucingo lwensimbi, kuqinile kakhulu.

Uma unezidingo ezikhethekile, ungasebenzisa ukupakisha okuvikela ukugqwala, futhi kube kuhle kakhulu.

Ezokuthutha:Ukuthunyelwa Okusheshayo (Ukulethwa Kwesampula), Umoya, Isitimela, Umhlaba, Ukuthunyelwa Kwasolwandle (i-FCL noma i-LCL noma i-Bulk)

Ikhasimende Lethu

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi bamashubhu ensimbi ejikelezayo edolobhaneni laseDaqiuzhuang, edolobheni laseTianjin, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

U: Ingabe unezinga eliphezulu lokukhokha?

A: Nge-oda elikhulu, izinsuku ezingama-30-90 L/C zingamukeleka.

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Singumhlinzeki weminyaka eyisikhombisa obandayo futhi samukela isiqinisekiso sokuhweba.