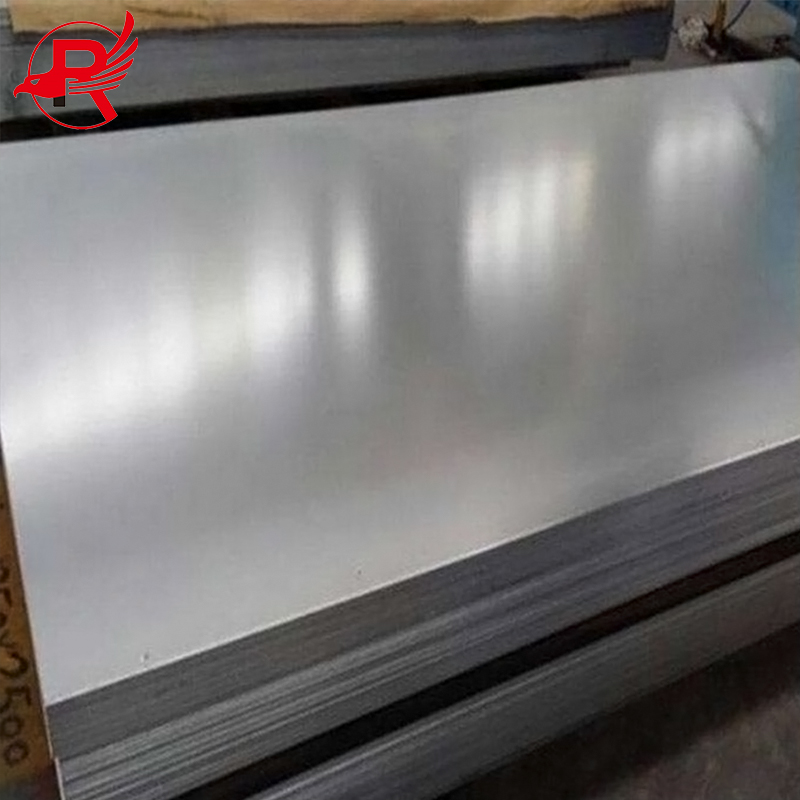

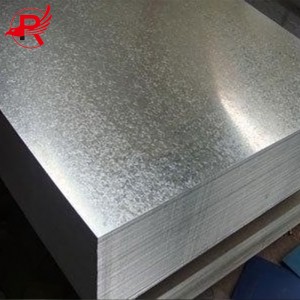

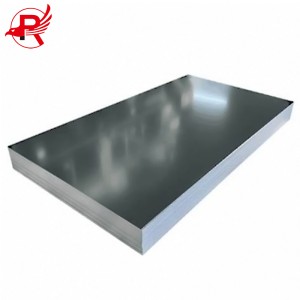

Ishidi Lensimbi Eligayiwe le-SGCE 1mm 3mm 5mm 6mm Ipuleti Lensimbi Elisezingeni Elihle

Amashidi ensimbi e-GI angamashidi enziwe ngensimbi ehlanganisiwe (GI). I-Galvanization inqubo yokumboza insimbi noma insimbi ngesendlalelo se-zinc ukuvimbela ukugqwala. Amashidi e-GI avame ukusetshenziswa ekufuleni, ekubiyeleni, nasekusetshenzisweni kwangaphandle ngenxa yokuqina kwawo kanye nokumelana nokugqwala nokugqwala.

Ubukhulu bamashidi e-GI bulinganiswa nge-gauge, kanti i-gauge ephansi ibonisa ishidi elijiyile. Ama-gauge avame kakhulu amashidi e-GI asukela ku-18 kuya ku-24. Ububanzi bamashidi e-GI buvame ukusuka ku-600mm kuya ku-1500mm.

Ipuleti Lensimbi Elakhiwe Nge-GalvanizedAtholakala ngezinhlobo ezimbili zokumboza: i-spangle ejwayelekile kanye ne-zero spangle. Amashidi e-GI ajwayelekile e-spangle anephethini ebonakalayo efana ne-spangle ebusweni, edalwa ngesikhathi senqubo yokugaya i-galvanizing. Amashidi e-GI angenayo i-spangle, ngakolunye uhlangothi, anobuso obubushelelezi futhi awanawo iphethini ebonakalayo ye-spangle.

Ishidi Lensimbi Eligayiwezingahlukaniswa futhi ngokusekelwe ekusetshenzisweni kwazo. Ezinye zezinhlobo ezivamile zamashidi e-GI zifaka:

1. Amashidi e-GI ane-corrugated - asetshenziselwa ukufulela, amaphaneli odonga, kanye nokubiyela.

2. Amashidi e-GI alula - asetshenziselwa izinhlelo zangaphakathi ezifana nokufaka ipayipi, amaphaneli kagesi, kanye nefenisha.

3. Amashidi e-Galvalume GI - inhlanganisela yamashidi e-GI ambozwe nge-aluminium kanye ne-zinc anikeza ukumelana okuhle kokugqwala.

4. Amashidi e-GI apendwe ngaphambilini - amashidi e-GI ambozwe ngesendlalelo sopende, avame ukusetshenziswa ekufakeni uphahla kanye nokufakwa kwe-cladding.

Amashidi e-GI atholakala ngamamaki ahlukahlukene ngokusekelwe emandleni awo nokuqina kwawo. Amamaki asetshenziswa kakhulu kumashidi e-GI yi-SGCC, SGHC, kanye ne-DX51D.

1. Ukumelana nokugqwala, ukupendwa kalula, ukwakheka kahle kanye nokushiselwa kwamabala.

2. Inezindlela eziningi zokusebenzisa, ikakhulukazi ezisetshenziselwa izingxenye zezinto zasekhaya ezincane ezidinga ukubukeka okuhle, kodwa ibiza kakhulu kune-SECC, ngakho abakhiqizi abaningi bashintshela ku-SECC ukuze bonge izindleko.

3. Ihlukaniswe yi-zinc: ubukhulu be-span kanye nobukhulu besendlalelo se-zinc kungabonisa ikhwalithi ye-galvanizing, uma incane futhi ikhulu kakhulu kungcono. Abakhiqizi bangangeza nokwelashwa okulwa nokunyathelisa iminwe. Ngaphezu kwalokho, ingahlukaniswa ngesendlalelo sayo, njenge-Z12, okusho ukuthi inani eliphelele lesendlalelo kuzo zombili izinhlangothi lingu-120g/mm.

Amashidi e-GI anezindlela ezahlukahlukene zokusetshenziswa ezimbonini nasemikhakha ehlukene. Ezinye zezindlela ezivamile zokusetshenziswa kwamashidi e-GI yilezi:

1. Uphahla kanye Nokumbozwa:Ipuleti Lensimbi Elishisayo Eligayiweziyinketho ethandwayo yokusetshenziswa kophahla kanye nokufakwa kwendwangu ngenxa yokuqina kwazo, ukumelana nokugqwala, kanye nokuqina. Zivame ukusetshenziswa ezakhiweni zokuhlala, zezentengiselwano, kanye nezezimboni.

2. Uthango: Amashidi e-GI asetshenziselwa ukwakha uthango kanye nodonga ngenxa yamandla awo kanye nezakhiwo zokumelana nokugqwala. Asetshenziswa futhi njengezindonga zomngcele ngezinjongo zokuphepha.

3. Izimoto: Amashidi e-GI asetshenziselwa ukukhiqiza izingxenye zezimoto ezifana namaphaneli omzimba, uphahla, kanye ne-chassis ngenxa yamandla nokuqina kwawo.

4. I-HVAC: Amashidi e-GI asetshenziswa embonini yokushisa, ukungenisa umoya, kanye ne-air conditioner (i-HVAC) kuma-ducting, amayunithi okupholisa umoya, kanye nezinhlelo zokungenisa umoya.

5. Ukwenziwa: Amashidi e-GI asetshenziswa embonini yokwenziwa ukukhiqiza imikhiqizo ehlukahlukene efana namakhabethe, amashalofu, ifenisha, neminye imikhiqizo yensimbi.

6. Ugesi: Amashidi e-GI asetshenziselwa ukukhiqiza amaphaneli okuvala kagesi ngenxa yokuqina kwawo, amandla, kanye nokumelana nokugqwala.

7. Ezolimo: Amashidi e-GI asetshenziswa kwezolimo ekwakheni amashede ezinkukhu, izindawo zokugcina izithombo, kanye nezindawo zokugcina.

Sekukonke, amashidi e-GI anikeza ikhambi elithembekile nelingabizi kakhulu lezinhlelo zokusebenza eziningi futhi asetshenziswa kabanzi ezimbonini nasemikhakha eminingi.

| Izinga Lobuchwepheshe | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga Lensimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); noma kwamakhasimende Isidingo |

| Ubukhulu | imfuneko yekhasimende |

| Ububanzi | ngokwezidingo zekhasimende |

| Uhlobo Lokumboza | Insimbi Eshisayo Ecwiliswe Ngogesi (HDGI) |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa (C), Ukufaka uwoyela (O), Ukuvala i-Lacquer (L), Ukuphosphating (P), Okungaphathwanga (U) |

| Isakhiwo Somphezulu | Ukugqoka okujwayelekile kwe-spangle (NS), ukugqoka okuncishisiwe kwe-spangle (MS), okungena-spangle (FS) |

| Ikhwalithi | Kuvunywe yi-SGS, ISO |

| ID | 508mm/610mm |

| Isisindo sekhoyili | I-metric ton engu-3-20 nge-coil ngayinye |

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Imakethe yokuthumela ngaphandle | IYurophu, i-Afrika, i-Asia Ephakathi, iNingizimu-mpumalanga ye-Asia, iMpumalanga Ephakathi, iNingizimu Melika, iNyakatho Melika, njll. |

| Ithebula Lokuqhathanisa Ubukhulu Begeji | ||||

| Igeyiji | Okuncane | I-Aluminium | I-Galvanised | Insimbi Engagqwali |

| Igeyiji 3 | 6.08mm | 5.83mm | 6.35mm | |

| Igeyiji 4 | 5.7mm | 5.19mm | 5.95mm | |

| Igeyiji 5 | 5.32mm | 4.62mm | 5.55mm | |

| Igeyiji 6 | 4.94mm | 4.11mm | 5.16mm | |

| Igeyiji 7 | 4.56mm | 3.67mm | 4.76mm | |

| Igeyiji 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Igeyiji 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Igeyiji 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Igeyiji 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Igeyiji 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Igeyiji 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Igeyiji 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Igeyiji 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Igeyiji 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Igeyiji 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Igeyiji 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Igeyiji 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Igeyiji 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Igeyiji 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Igeyiji 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Igeyiji 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Igeyiji 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Igeyiji 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Igeyiji 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Igeyiji 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Igeyiji 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Igeyiji 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Igeyiji 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Igeyiji 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Igeyiji 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Igeyiji 33 | 0.22mm | 0.18mm | 0.24mm | |

| Igeyiji 34 | 0.20mm | 0.16mm | 0.22mm | |

1. Angakanani amanani akho?

Amanani ethu angashintsha kuye ngokuthi ukunikezwa kwempahla kuyatholakala yini kanye nezinye izici zemakethe. Sizokuthumelela uhlu lwamanani olubuyekeziwe ngemuva kokuxhumana nenkampani yakho.

nathi ukuze uthole ulwazi olwengeziwe.

2. Ingabe unenani elincane kakhulu le-oda?

Yebo, sidinga ukuthi wonke ama-oda aphesheya abe nenani elincane eliqhubekayo le-oda. Uma ufuna ukuthengisa kabusha kodwa ngamanani amancane kakhulu, sincoma ukuthi uhlole iwebhusayithi yethu.

3. Ungakwazi yini ukunikeza amadokhumenti afanele?

Yebo, singanikeza imibhalo eminingi kufaka phakathi Izitifiketi Zokuhlaziya/Ukuhambisana; Umshwalense; Umsuka, kanye neminye imibhalo yokuthumela ngaphandle lapho kudingeka khona.

4. Singakanani isikhathi esimaphakathi sokuhola?

Kumasampula, isikhathi sokuhola cishe siyizinsuku eziyi-7. Ekukhiqizweni ngobuningi, isikhathi sokuhola siyizinsuku ezi-5-20 ngemuva kokuthola inkokhelo yediphozithi. Izikhathi zokuhola ziqala ukusebenza uma

(1) sesiyitholile idiphozithi yakho, futhi (2) sinemvume yakho yokugcina yemikhiqizo yakho. Uma izikhathi zethu zokukhokha zingasebenzi ngesikhathi sakho sokugcina, sicela ubuyekeze izidingo zakho ngokuthengisa kwakho. Kuzo zonke izimo sizozama ukuhlangabezana nezidingo zakho. Ezimweni eziningi siyakwazi ukwenza kanjalo.

5. Yiziphi izinhlobo zezindlela zokukhokha ozamukelayo?

U-30% kusengaphambili nge-T/T, u-70% uzoba ngaphambi kokuthunyelwa okuyisisekelo ku-FOB; u-30% kusengaphambili nge-T/T, u-70% uma kuqhathaniswa nekhophi ye-BL eyisisekelo ku-CIF.