Ishubhu Yensimbi Yensimbi Eyikhwalithi Ephezulu ye-Gi Iyathengiswa

Ipayipi elishisayo lokucwilisayenziwe ngensimbi encibilikisiwe nensimbi matrix ukusabela ukukhiqiza ingxubevange ungqimba, ukuze matrix kanye enamathela inhlanganisela ezimbili.I-Hot dip galvanizing ukuqala ukukha ishubhu lensimbi.Ukuze kukhishwe i-iron oxide ebusweni beshubhu lensimbi, ngemva kokukhetha, ihlanzwa ethangini le-ammonium chloride noma isixazululo se-zinc chloride noma isixazululo esinamanzi esixubile se-ammonium chloride ne-zinc chloride, bese sithunyelwa ediphini elishisayo. ithangi.I-hot dip galvanizing inezinzuzo zokuhlanganisa iyunifomu, ukunamathela okuqinile nempilo ende yesevisi.Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwesisekelo seshubhu lensimbi kanye nokugeza okuncibilikisiwe ukuze kwakhe ungqimba oluhlangene lwengxube ye-zinc-iron olumelana nokugqwala.Isendlalelo se-alloy sihlanganiswe nesendlalelo se-zinc ehlanzekile kanye ne-steel tube matrix.Ngakho-ke, ukumelana kwayo nokugqwala kunamandla.

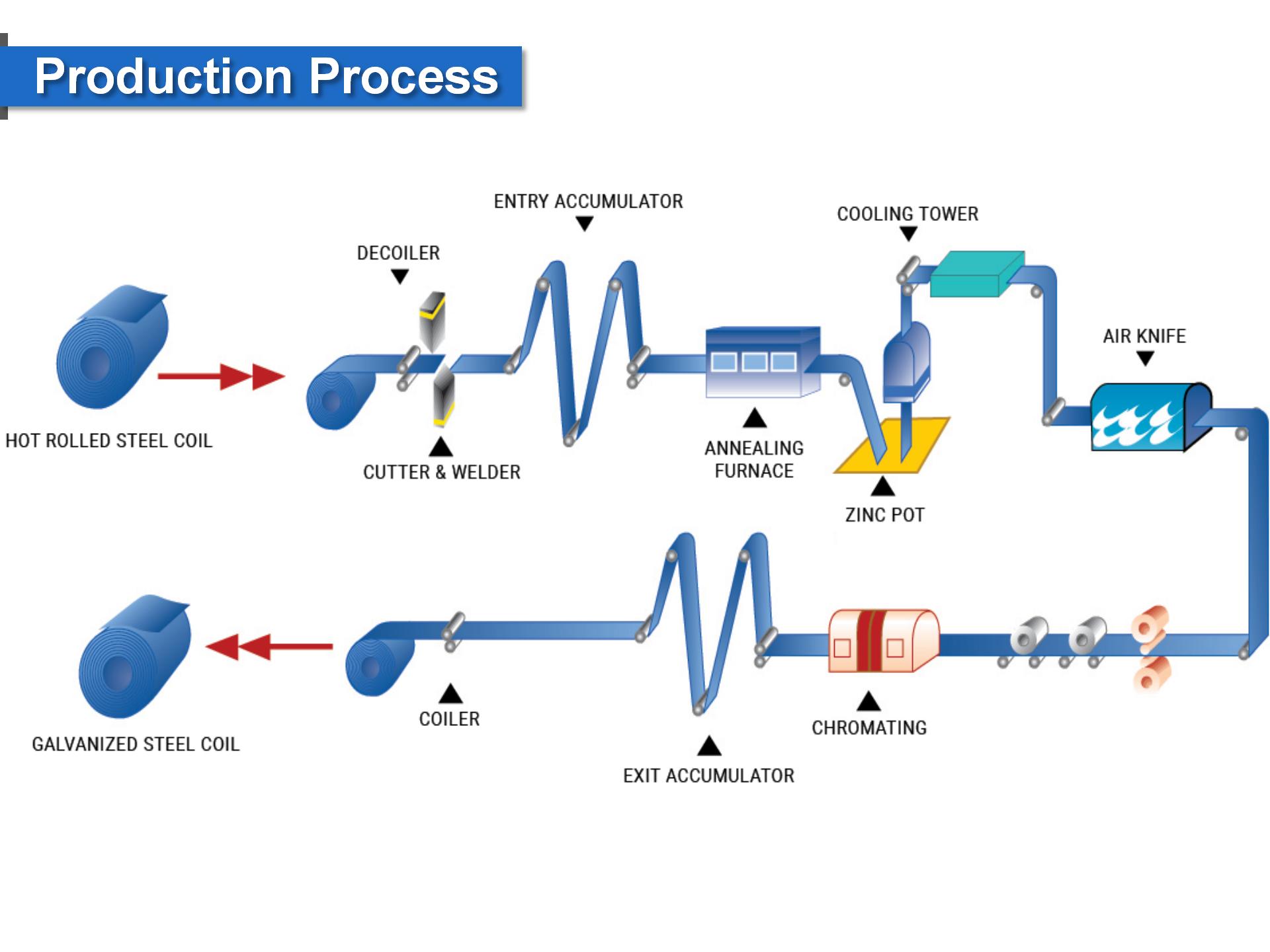

Iinqubo yokukhiqizaipayipi lensimbi ebilisiwe kuhlanganisa lezi zinyathelo ezilandelayo:

1. Amakhoyili ensimbi: Amapayipi ensimbi akhiwe ngamakhoyili ensimbi asezingeni eliphezulu ashiswayo afinyelele ubukhulu obufunayo kanye nokuma.

2. Ukuhlanza: Ikhoyili yensimbi iyahlanzwa ukuze kukhishwe noma yikuphi ukugqwala, uwoyela noma okunye ukungcola okungase kuphazamise ikhwalithi yomkhiqizo wokugcina.

3. I-Flux: Ikhoyili idluliswa kubhavu we-flux oqukethe ingxube ye-zinc ammonium chloride.Lesi sixazululo sisiza ukususa noma yikuphi ukungcola okusele futhi silungiselela indawo yensimbi yesinyathelo esilandelayo.

4. I-galvanizing: Gcobhoza ikhoyili ku-zinc encibilikisiwe ukuze uvale ngokuphelele ingaphezulu lensimbi.Le nqubo ngezinye izikhathi ibizwa ngokuthi i-hot dip galvanizing.

5. Ukupholisa: Pholisa ikhoyili ngemva kokuvuthela ukuze uqine ungqimba lwezinki.

6. Ukusika nokwakha: Ikhoyili iyasikwa ibe yibude obufunayo bese yenziwa ishubhu.

7. Ukuhlola: Amashubhu ayahlolwa ukuze kuqinisekiswe ukuthi ahlangabezana nezindinganiso ezidingekayo zamandla, ukuqina nokumelana nokugqwala.

8. Isitoreji nokusabalalisa: Amashubhu abe esegcinwa futhi asatshalaliswe kumakhasimende.

Inqubo yokukhiqiza ipayipi yensimbi enama-galvanized ilula futhi ikhiqiza izinga eliphezulu, umkhiqizo oqinile ofanele ukusetshenziswa okubanzi.

Izici

1. Ukumelana nokugqwala: Ukugalela kuyindlela yokuvikela ukugqwala kwezomnotho nephumelelayo evame ukusetshenziswa.Cishe ingxenye yomkhiqizo we-zinc emhlabeni isetshenziswa kule nqubo.Akukhona nje ukuthi i-zinc yakha isendlalelo esiqinile sokuzivikela endaweni yensimbi, kodwa futhi inomphumela wokuvikela we-cathodic.Lapho i-zinc enamathelayo ilimele, isengakwazi ukuvimbela ukugqwala kwesisekelo sensimbi ngokuvikelwa kwe-cathodic.

2. Ukugoba okuhle okubandayo nokusebenza kokushisela: ikakhulukazi esetshenziswa ibanga eliphansi le-carbon steel, izidingo zinokugoba okuhle okubandayo nokusebenza kokushisela, kanye nokusebenza okuthile kokugxiviza.

3. I-Reflectivity: Inokubonakala okuphezulu, okuyenza ibe isithiyo ngokumelene nokushisa

I-4, ukuqina kokugqoka kunamandla, ungqimba olunamanzi lwakha isakhiwo esikhethekile se-metallurgical, lesi sakhiwo singakwazi ukumelana nokulimala komshini ekuthuthweni nasekusetshenzisweni.

Isicelo

Imikhiqizo yamakhoyili enziwe ngamagalani isetshenziswa kakhulu kwezokwakha, ezimbonini ezilula, ezezimoto, ezolimo, ezemfuyo, ezokudoba kanye nezimboni zezohwebo.Imboni yezokwakha isetshenziselwa ikakhulukazi ukwakha amaphaneli ophahla lwezimboni ezilwa nokugqwala, amagridi ophahleni, njll. Imboni yokukhanya iyisebenzisela ukwakha amagobolondo ezinto zasendlini, ushimula womphakathi, izitsha zasekhishini, njll., futhi imboni yezimoto esetshenziswa kakhulu ukwenza izingxenye zezimoto ezingagqwali.Ezolimo, ukufuywa kwezilwane kanye nezokudotshwa kwezinhlanzi kusetshenziswa kakhulu njengendawo yokugcina ukudla kanye nokuthutha, inyama nemikhiqizo yasemanzini okokusebenza okuqandisiwe, njll. Izentengiso zisetshenziswa kakhulu njengendawo yokugcina impahla kanye nezinto zokuhamba, amathuluzi okupakisha,

Amapharamitha

| Igama lomkhiqizo | Ipayipi Elivunyiwe |

| Ibanga | Q235B, SS400, ST37, SS41, A36 njll |

| Ubude | I-6m ejwayelekile kanye ne-12m noma njengemfuneko yekhasimende |

| Ububanzi | 600mm-1500mm, ngokuvumelana nemfuneko yekhasimende |

| Ezobuchwepheshe | Okushisayo Okucwiliswe Ngamagalaniipayipi |

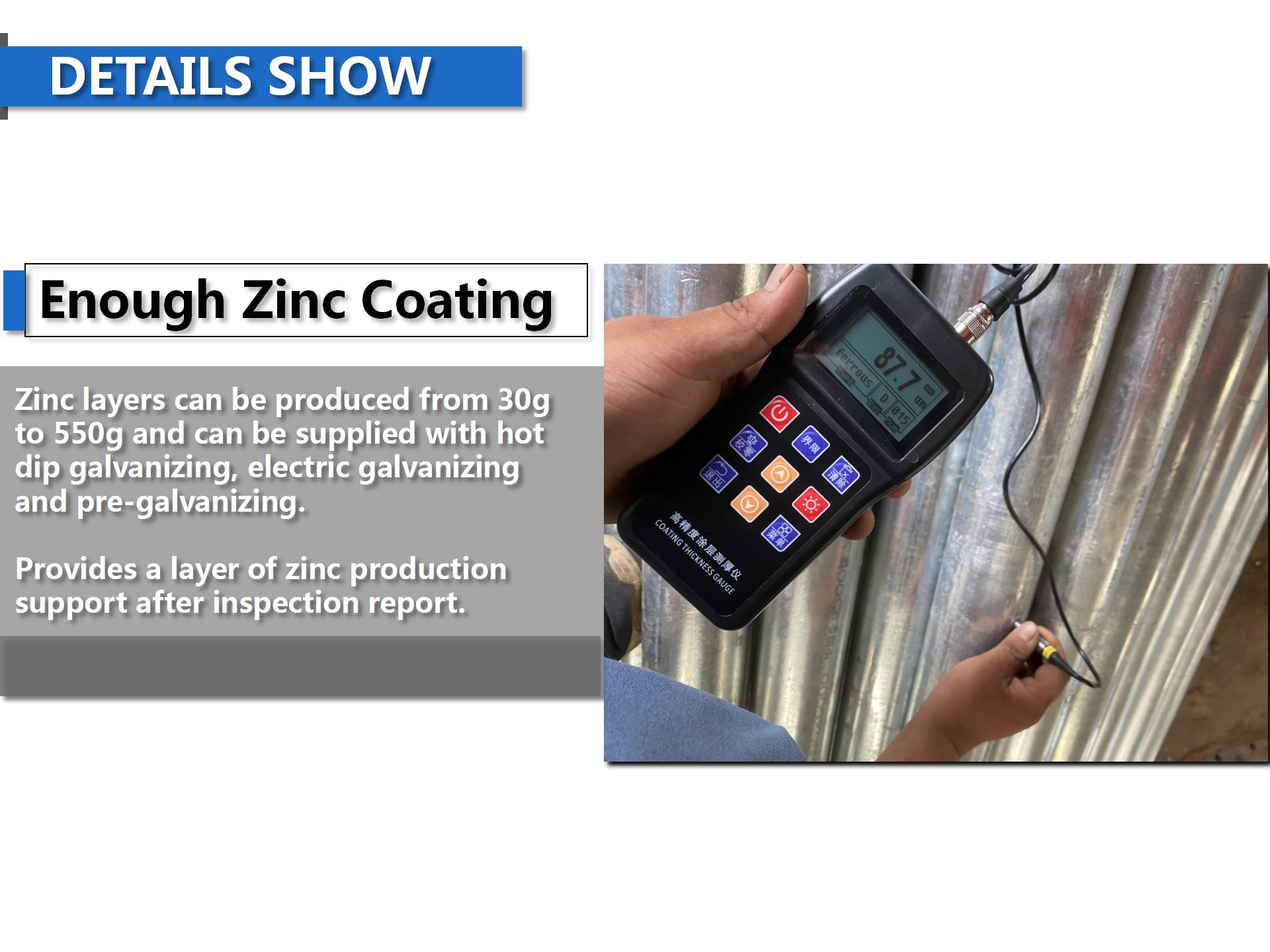

| I-Zinc Coating | 30-275g/m2 |

| Isicelo | Isetshenziswa kabanzi ezakhiweni ezahlukahlukene zokwakha, amabhuloho, izimoto, ama-bracker, imishini njll. |

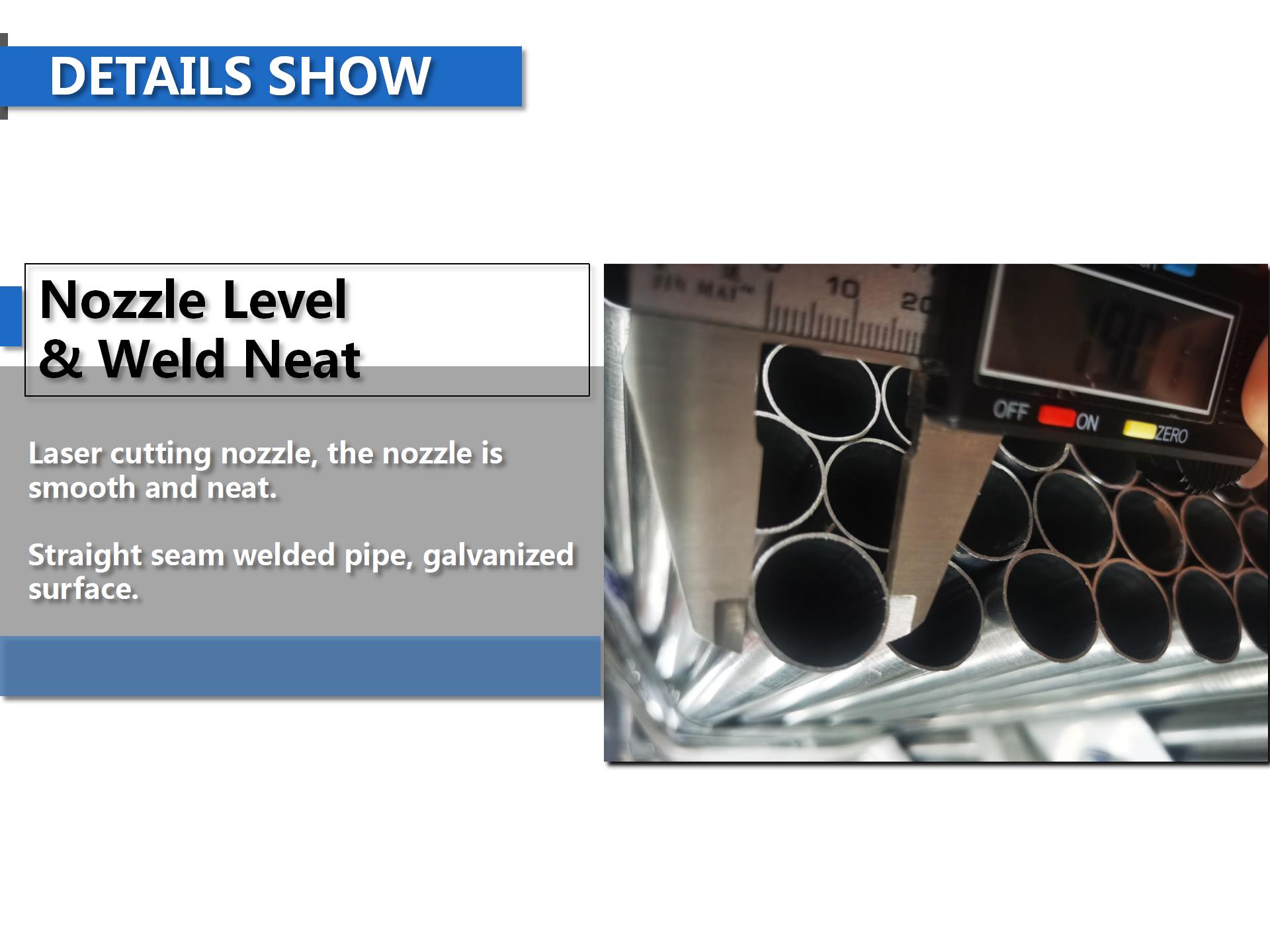

Imininingwane

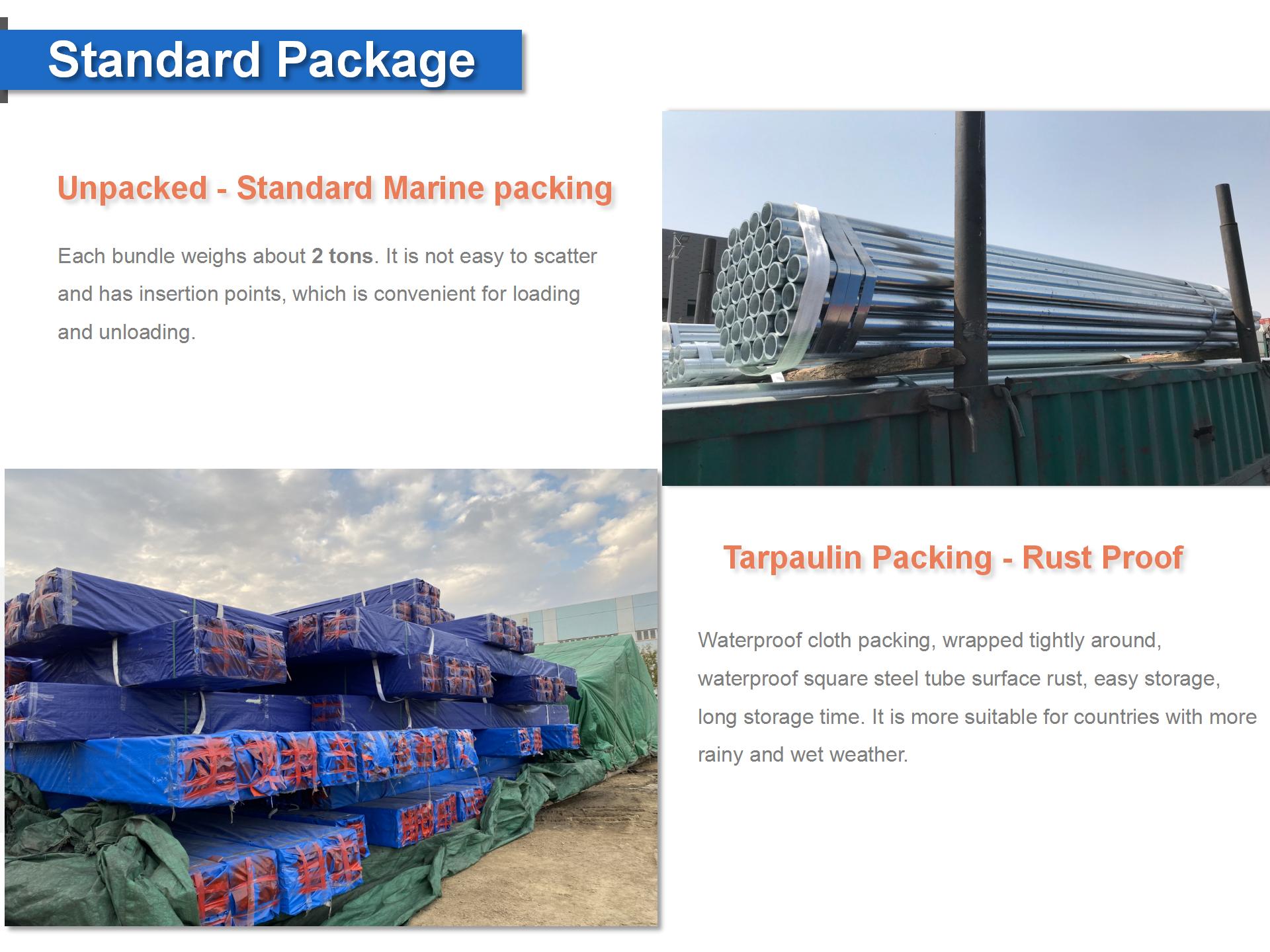

Ithubhu eyindilinga yensimbi egayiweukupakisha kuvame ukufaka izinyathelo ezilandelayo:

1. Amapayipi ayindilinga ensimbi aphehlwayo ayahlolwa ukuthi awakho yini amaphutha noma umonakalo ngaphambi kokupakisha.

2. Bese usebenzisa amabhande ensimbi noma epulasitiki ukuze ubophe amashubhu ndawonye ukuze uwabambe aqine endaweni yawo.

3. Bese ubeka amashubhu ahlanganisiwe phezu kwephalethi noma ekhreyithi, bese wengeza amakhadibhodi noma izikhala zokhuni phakathi kongqimba lwamashubhu ukuvimbela ukungqubuzana phakathi kokuhamba.

4. Iphalethi noma ikhreyithi libe seligoqwa ngefilimu yepulasitiki evikelayo ukuze kuqhutshekwe nokuvikela ishubhu futhi kuvinjwe noma yimuphi umswakama noma imfucumfucu ukuthi ingangeni ngaphakathi.

5. Okokugcina, ishubhu linamathiselwe ngolwazi olunjengosayizi, ubuningi kanye nanoma yimiphi eminye imininingwane efanele ukuze kusize isitoreji kanye nokuhlonza lapho uya khona.

Ukupakishwa ngendlela efanele kwamapayipi ayindilinga ensimbi kubaluleke kakhulu ukuze kuqinisekiswe ukuthi afika lapho aya khona esesimweni esihle ngaphandle komonakalo omncane noma ukugqwala.

1. Athini amanani akho?

Izintengo zethu zingashintsha kuye ngokuhlinzekwa nezinye izici zemakethe.Sizokuthumelela uhlu lwamanani olubuyekeziwe ngemuva kokuxhumana nenkampani yakho

nathi ukuze uthole ulwazi olwengeziwe.

2. Ingabe unenani elincane le-oda?

Yebo, sidinga wonke ama-oda wamazwe ngamazwe ukuthi abe nenani eliqhubekayo le-oda elincane.Uma ufuna ukuthengisa kabusha kodwa ngamanani amancane kakhulu, sincoma ukuthi uhlole iwebhusayithi yethu

3. Ungakwazi yini ukunikeza imibhalo efanele?

Yebo, singanikeza imibhalo eminingi ehlanganisa Izitifiketi Zokuhlaziya / Ukuvumelana;Umshwalense;Umsuka, namanye amadokhumenti okuthekelisa lapho kudingeka.

4. Singakanani isikhathi sokuhola esimaphakathi?

Kumasampuli, isikhathi sokuhola cishe yizinsuku eziyi-7.Ngokukhiqizwa okukhulu, isikhathi sokuhola siyizinsuku ezingu-5-20 ngemuva kokuthola inkokhelo yediphozithi.Izikhathi zokuhola zisebenza kahle uma

(1) siyitholile idiphozithi yakho, futhi (2) sinemvume yakho yokugcina yemikhiqizo yakho.Uma izikhathi zethu zokuhola zingasebenzi nomnqamulajuqu wakho, sicela uhlole izidingo zakho ngokuthengisa kwakho.Kuzo zonke izimo sizozama ukwanelisa izidingo zakho.Ezimweni eziningi siyakwazi ukwenza kanjalo.

5. Yiziphi izinhlobo zezindlela zokukhokha ozamukelayo?

U-30% kusengaphambili nge-T/T, u-70% uzoba ngaphambi kokuthunyelwa okuyisisekelo ku-FOB;30% kusengaphambili nge-T/T, 70% uma kuqhathaniswa nekhophi ye-BL eyisisekelo ku-CIF.