IngagugiSithiPsekwephuzile

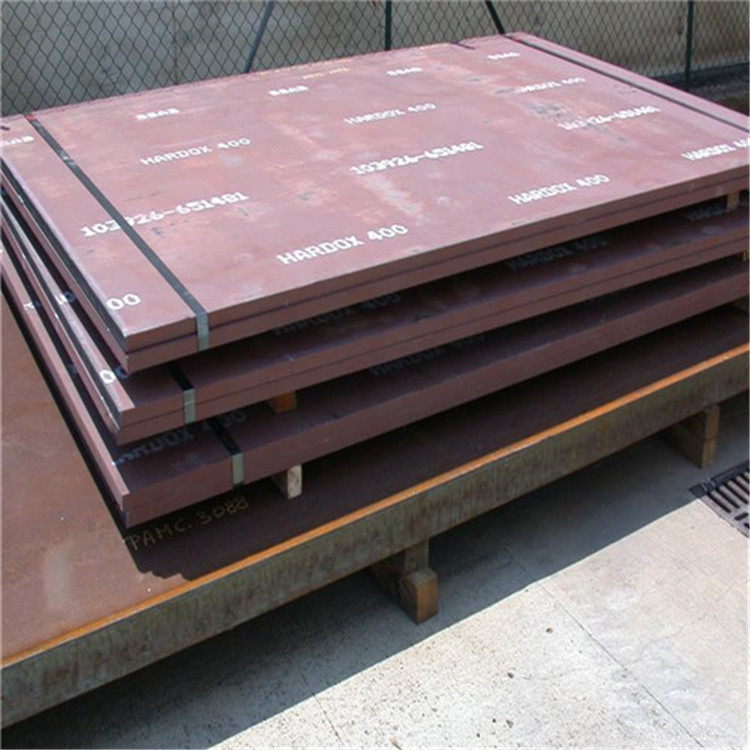

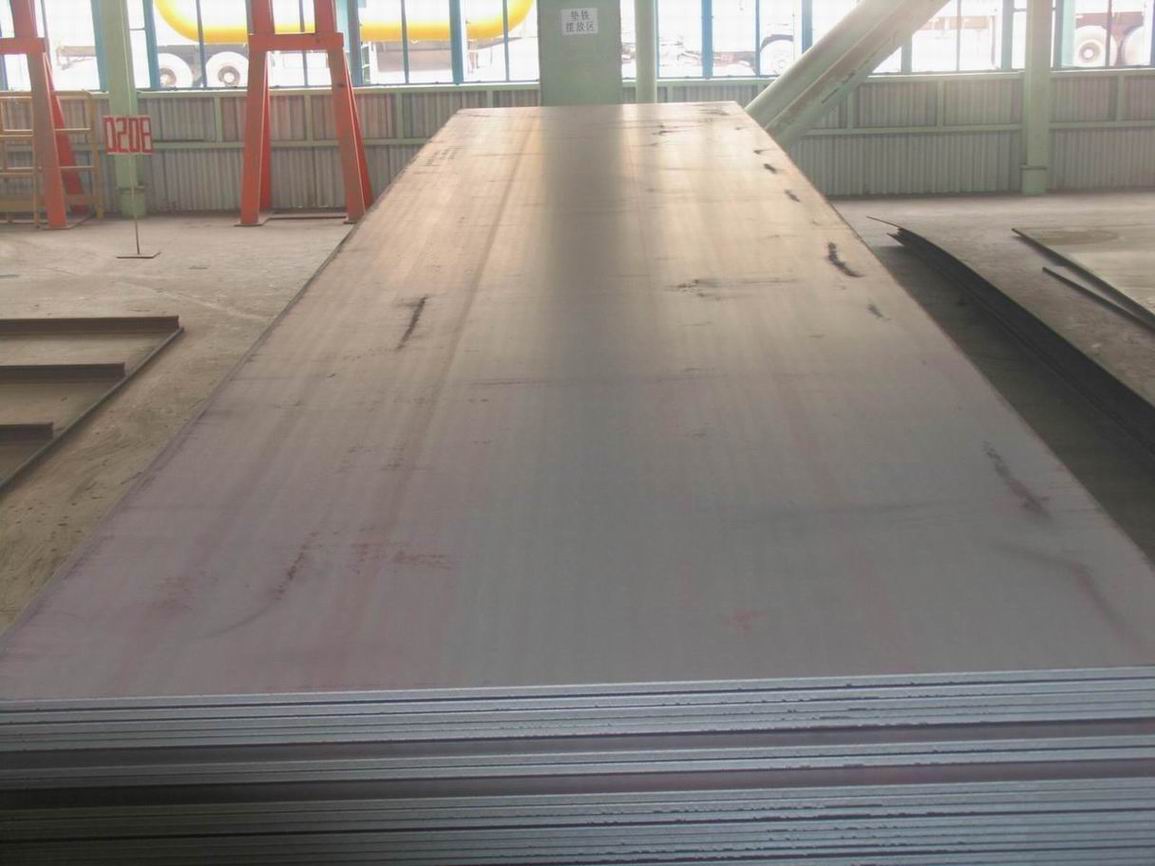

Ipuleti lensimbi elinezinsimbi ezigqoke kabili ezigqokekayo umkhiqizo wepuleti osetshenziselwa ngokukhethekile izimo zokugqokwa kwendawo enkulu.Yenziwe ngensimbi ye-low-carbon steel evamile noma i-low-alloy steel enokuqina okuhle kanye nepulasitiki.Umkhiqizo wepuleti owenziwe ngongqimba olungagugi olunokuqina okuhle kakhulu.

Ipuleti lensimbi elikwazi ukumelana nokugqokwa kwe-bimetal lakhiwa ipuleti lensimbi elinekhabhoni ephansi kanye nongqimba olumelana nokufakwa kwe-alloy.Ungqimba olungagugi ngokuvamile lubalelwa ku-1/3-1/2 wogqinsi oluphelele.Lapho isebenza, i-matrix inikeza izici eziphelele ezifana namandla, ukuqina kanye nepulasitiki ngokumelene namandla angaphandle, futhi ungqimba olumelana nokugqoka luhlinzeka ngezakhiwo ezingagugi ezihlangabezana nezidingo zezimo zokusebenza ezicacisiwe.

Isendlalelo esingagugi ngokuyinhloko sakhiwe ingxubevange ye-chromium, nezinye izakhi ze-alloy ezifana ne-manganese, i-molybdenum, i-niobium, ne-nickel yengezwa ngesikhathi esifanayo.Ama-carbides esakhiweni se-metallographic asatshalaliswa ngendlela ye-fiber, futhi isiqondiso se-fiber sibheke phezulu.I-carbide microhardness ingafinyelela ngaphezu kwe-HV1700-2000, futhi ubulukhuni bobuso bungafinyelela ku-HRc58-62.I-alloy carbides inokuqina okuqinile emazingeni okushisa aphezulu, igcina ubulukhuni obukhulu, futhi inokumelana okuhle ne-oxidation, futhi ingasetshenziswa ngokujwayelekile ngaphakathi kwama-500.°C.

Ipuleti lensimbi elingagqoki linokumelana nokugqokwa okuphezulu nokusebenza okuhle komthelela, futhi lingasikwa, ligobe, lishiselwe, njll., futhi lingaxhunywa nezinye izakhiwo ngokushisela, ukushisela ipulaki, ukuxhunywa kwebhawodi, njll., okonga isikhathi inqubo yokulungisa indawo , lula kanye nezinye izici, esetshenziswa kabanzi kwezensimbi, amalahle, usimende, amandla kagesi, ingilazi, izimayini, izinto zokwakha, izitini namathayili nezinye izimboni, uma kuqhathaniswa nezinye izinto zokwakha, inezindleko eziphakeme zokusebenza, iye yathandwa izimboni nabakhiqizi abaningi ngokwengeziwe.

UokwangempelaFi-ormat

| Okubalulekile | Ubukhulu | Ububanzi | Ubude |

| I-NM360 | 8 | 2200 | 8000 |

| I-NM360 | 10 | 2200 | 8000 |

| I-NM360 | 15 | 2200 | 8000 |

| I-NM400 | 12 | 2200 | 8000 |

| NM500 | 16 | 2200 | 8000 |

| I-NM360 | 20 | 2200 | 10300 |

| I-NM450 | 25 | 2200 | 12050 |

| I-NM400 | 30 | 2200 | 8000 |

| I-NM360 | 35 | 2090 | 10160 |

| I-NM400 | 40 | 2200 | 8000 |

| I-NM400 | 45 | 2200 | 8000 |

| I-NM400 | 50 | 2200 | 8000 |

| I-NM360 | 60 | 2200 | 7000 |

| I-NM360 | 135 | 0635 | 2645 |

| I-NM400 | 70 | 2200 | 9500 |

| I-NM400 | 80 | 2200 | 8000 |

Aisicelo

1) Isikhungo samandla ashisayo: isigayo samalahle esinesivinini esiphakathi, i-fan impeller casing, i-dust collector inlet flue, ipayipi lomlotha, umugqa womshini wamabhakede, ipayipi lokuxhuma isihlukanisi, i-coal crusher liner, i-coal crusher liner, i-machine liner, i-burner burner, amalahle. lahla i-hopper kanye ne-funnel liner, ithayela lokusekela i-air preheater, i-vane ye-separator guide.Izingxenye ezibalulwe ngenhla azinazo izidingo eziphakeme kakhulu kubunzima nokumelana nokugqoka kwepuleti lensimbi elingagugi, futhi ipuleti lensimbi elingagugi elinogqinsi lwe-6-10mm lwe-NM360/400 lingasetshenziswa.

2) Igceke lamalahle: i-chute yokudla kanye nolayini lwefaneli, i-hopper bushing, i-fan blade, ipuleti elingaphansi, i-cyclone dust collector, i-coke guide liner, i-ball mill liner, i-drill bit stabilizer, i-screw feeder bell kanye nesihlalo esiyisisekelo, i-kneader ibhakede lining, i-ring feeder. , indawo yokulahla iloli.Indawo yokusebenza yegceke lamalahle inokhahlo, futhi kunezidingo ezithile zokumelana nokugqwala nokumelana nokugqokwa kwepuleti lensimbi elingagugi.Kunconywa ukusebenzisa ipuleti lensimbi elingagugi elinento engu-NM400/450 HARDOX400 nogqinsi luka-8-26mm.

3) Imboni kasimende: i-chute lining, i-end bushing, inqola uthuli lwe-cyclone, ama-classifier blades nama-guide blades, ama-fan blades nolayini, ulayini webhakede lokutakula, ipuleti elingaphansi le-screw conveyor, izingxenye zamapayipi, i-frit cooling plate Lining, i-conveyor trough lining.Lezi zingxenye zidinga futhi amapuleti ensimbi angagugi anokumelana kangcono nokugqokwa kanye nokumelana nokugqwala.Amapuleti ensimbi angagqoki anento engu-NM360/400 HARDOX400 nogqinsi luka-8-30mmd angasetshenziswa.

4) Imishini yokulayisha: ipuleti le-mill chain plate, ipuleti le-hopper lining, ipuleti lokubamba, ipuleti lokulahla iloli elizenzakalelayo, umzimba weloli lokulahla.Lokhu kudinga ipuleti lensimbi elingagugi elinokumelana nokugqokwa okuphezulu kakhulu kanye nokuqina.Kunconywa ukusebenzisa ipuleti lensimbi elingagugi elinento engu-NM500 HARDOX450/500 nogqinsi luka-25-45MM.

5) Imishini yezimayini: impahla yamaminerali, i-crusher liner yamatshe, i-blade, i-conveyor liner, i-baffle.Izingxenye ezinjalo zidinga ukumelana nokugqokwa okuphezulu kakhulu, futhi impahla etholakalayo yi-NM450/500 HARDOX450/500 ipuleti lensimbi elingagqoki elinogqinsi luka-10-30mm.

I-6) Imishini yokwakha: ipuleti lezinyo le-cement pusher, isakhiwo sokuxuba ukhonkolo, i-mixer liner, umshini wokuqoqa uthuli, ipuleti lokubumba lomshini wezitini.Kunconywa ukusebenzisa i-NM360/400 yensimbi engagqoki enogqinsi luka-10-30mm.

7) Imishini yokwakha: isilayishi, ugandaganda, ipuleti lebhakede le-excavator, ipuleti lonqenqema oluseceleni, ipuleti elingaphansi kwebhakede, i-blade, ipayipi lokubhola elijikelezayo.Lolu hlobo lwemishini ludinga amapuleti ensimbi angagugi aqine ngokukhethekile futhi amelane ngokwedlulele.Izinto ezitholakalayo yi-NM500 HARDOX500/550/600 amapuleti ensimbi aqinile angagugi anogqinsi luka-20-60mm.

I-8) Imishini ye-Metallurgical: umshini we-iron ore sintering, indololwane yokudlulisa, i-lining plate yomshini we-iron ore sintering, i-lining plate yomshini we-scraper.Ngoba lolu hlobo lwemishini ludinga ukumelana nokushisa okuphezulu, amapuleti ensimbi aqinile kakhulu angagugi.Ngakho-ke, kunconywa ukusebenzisa i-HARDOX600HARDOXHiTuf uchungechunge lwamapuleti ensimbi angagugi.

9) Amapuleti ensimbi angagugi angasetshenziswa futhi kumasilinda okugaya isihlabathi, izindwani, amayadi ezimpahla ahlukahlukene, izingxenye zemishini ye-wharf, izingxenye zesakhiwo, izingxenye zesakhiwo samasondo wesitimela, imiqulu, njll.

Isikhathi sokuthumela: Jul-04-2023